A kind of gluing method and gluing mechanism

A technology of gluing and priming, which is applied in coatings, devices for coating liquid on the surface, and surface pretreatment, etc. It can solve problems such as low work efficiency, manual operation, and serious physical injury, and achieve the improvement of gluing quality, Reasonable structure setting and the effect of optimizing the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

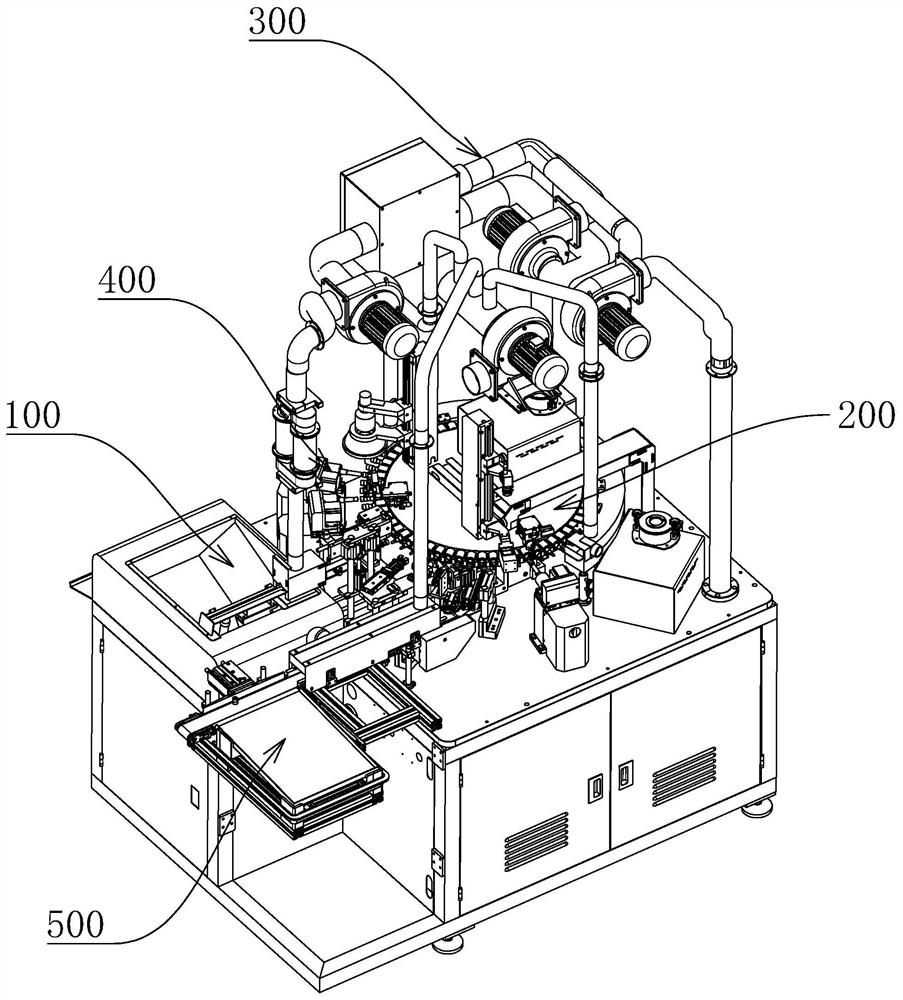

[0073] Such as Figure 1 to Figure 31 as shown,

[0074] The gluing mechanism includes:

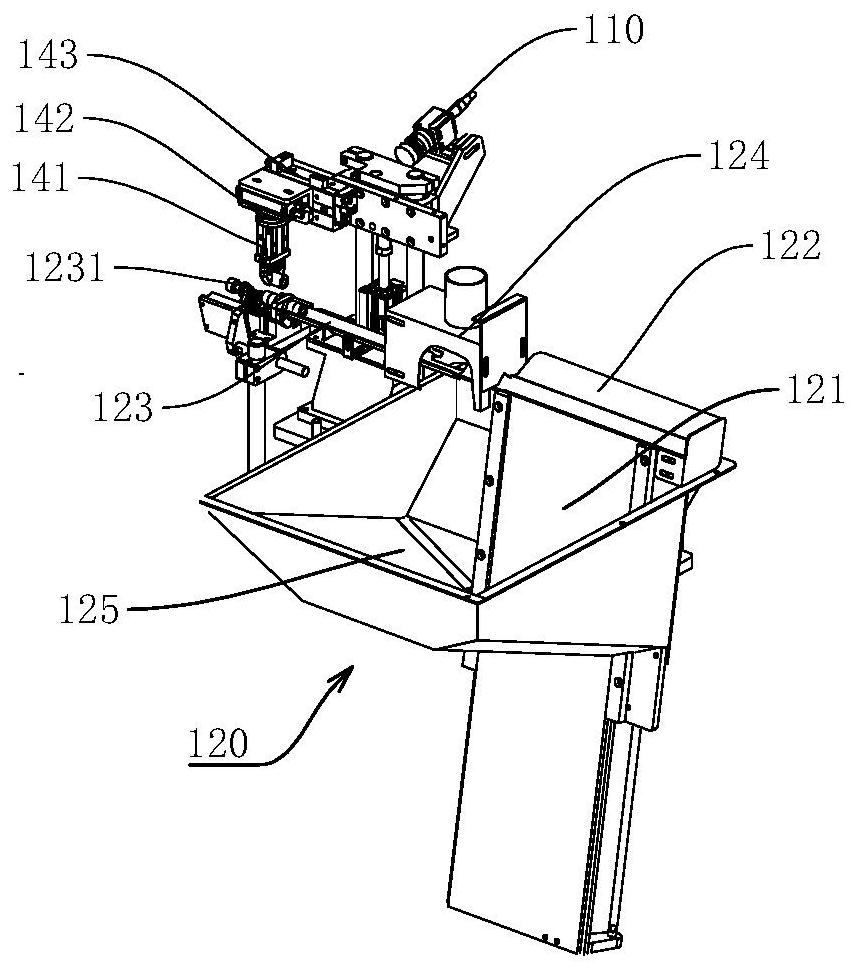

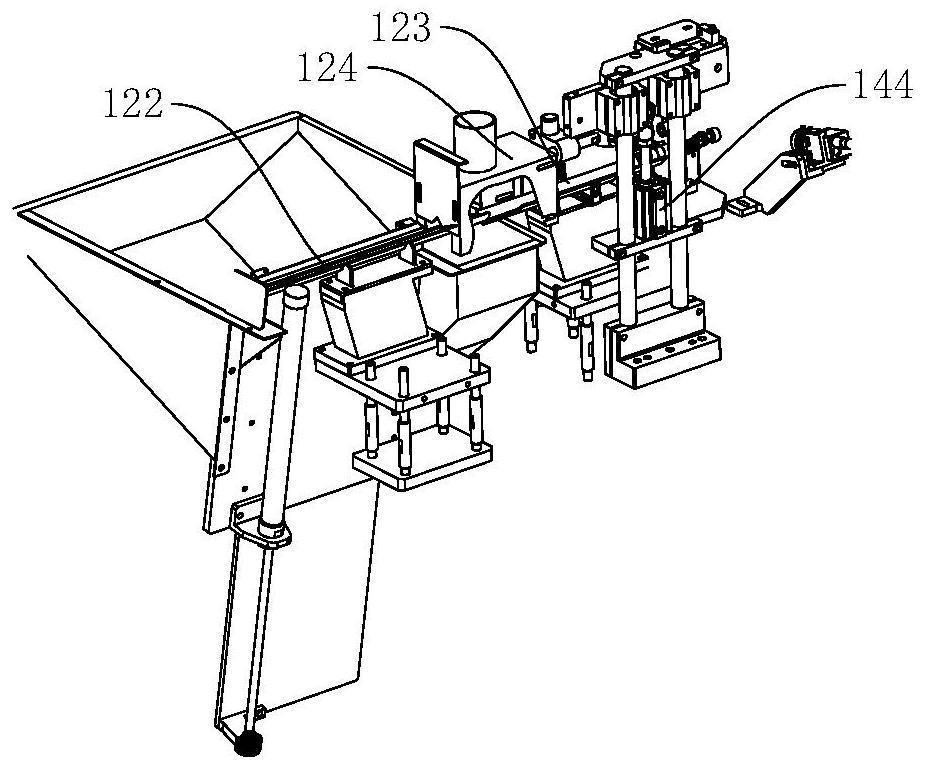

[0075] The feeding device 100 is used for the gluing mechanism, and the feeder 125 side of the feeder mechanism 120 is provided with a pusher plate 121, and the top of the pusher plate 121 is provided with a direct-vibration feeding guide rail 1 122 and a direct-vibration feeding guide rail 2 123. One end of feeding guide rail two 123 close to direct vibration feeding guide rail one 122 is provided with preheating box 124, and this preheating box 124 is used for the preheating of ring-shaped perforated parts, also includes being located at the top of direct vibration feeding guide rail two 123 The grabbing mechanism 140 for workpieces to be glued, the grabbing mechanism 140 for workpieces to be glued includes a jaw cylinder 141, a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com