Device For Cleansing And Adding Adhesion To Board

A board and cleaning technology, applied in the direction of the device for coating liquid on the surface, the pretreatment surface, the coating, etc., to achieve the effect of lifting and improving the adhesion and firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

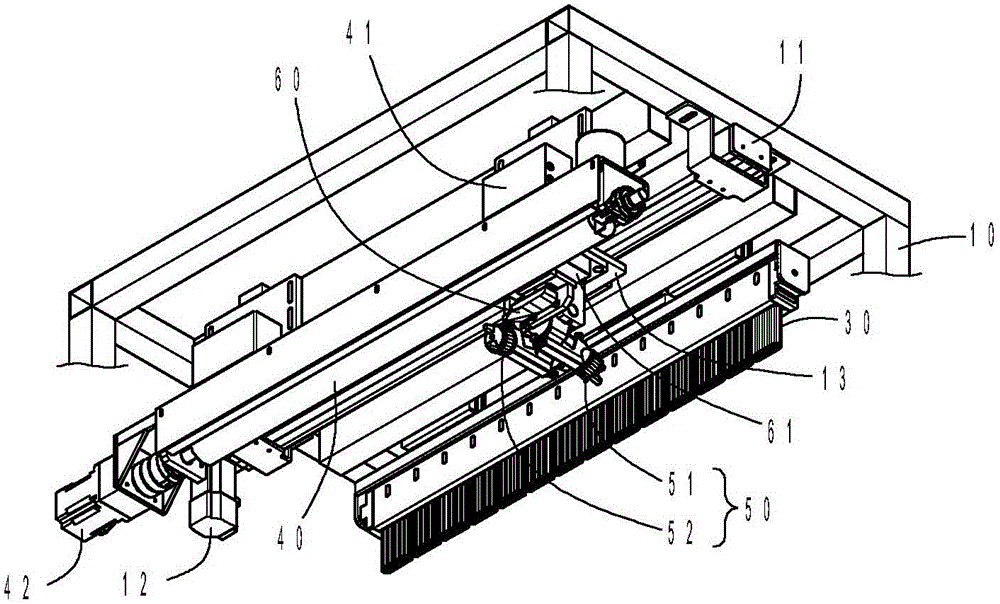

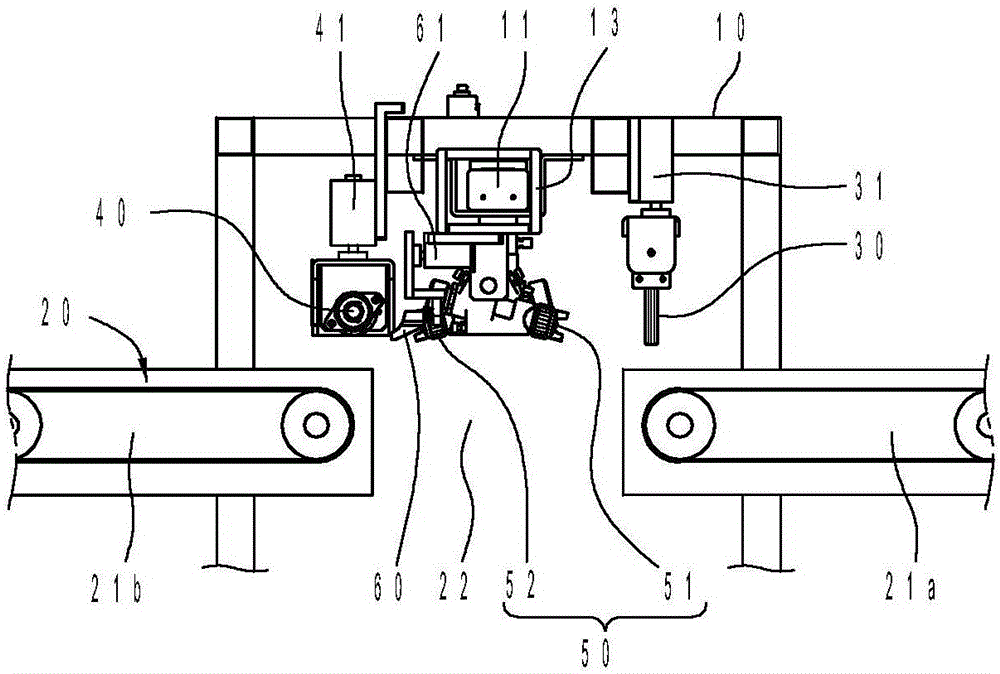

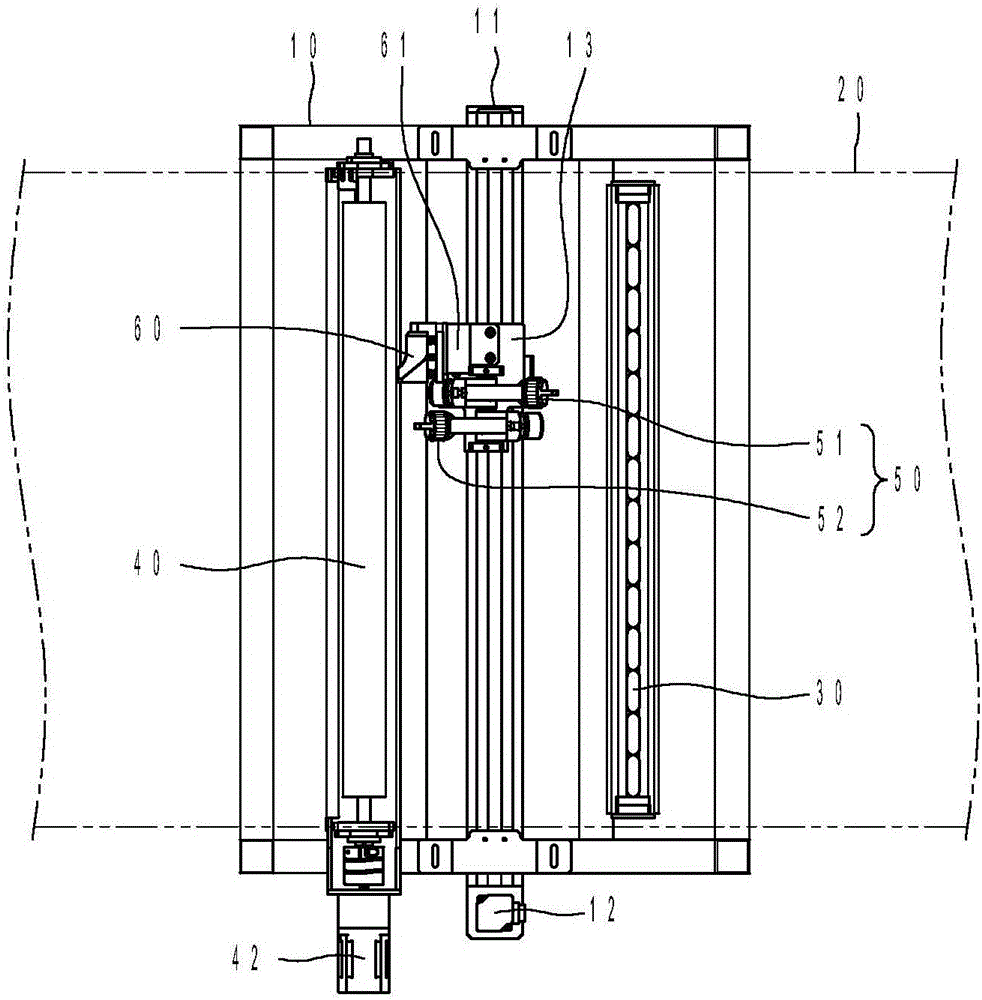

[0029] First, please incorporate the Figure 1 to Figure 3 , revealing the aspect of a preferred embodiment of the present invention, illustrating that the cleaning and adhesion-increasing device of the plate provided by the present invention includes a base 10, a conveying table 20, a brush 30, and a glue roller 40 And a nozzle group 50. in︰

[0030] The conveying table 20 can be constructed by rollers or belts in practice, and the conveying table 20 can be used to carry at least one or more boards 70 for movement, and the boards 70 can refer to LED light box assembly components cooling plate. Further speaking, the base platform 10 straddles the conveying platform 20 in an arched shape, so that the plates 70 carried by the conveying platform 20 can pass under the base platform 10 . In specific implementation, the conveying platform 20 is formed by connecting two roller or belt-type conveyor tables 21a, 21b in series, and a space 22 is formed between the two conveyor tables...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com