Cloth hot stamping digital anti-counterfeiting mark and preparation method thereof

An anti-counterfeiting mark and digital technology, applied in the field of anti-counterfeiting marks, can solve the problems of easy falling off, poor folding resistance of anti-counterfeiting marks, and inability of anti-counterfeiting marks to be washed with water, etc., so as to improve the adhesion firmness, realize automatic labeling, and enhance folding resistance. and the effect of washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] 1 million customer orders

[0067] (1) Choose a single-sided corona PET with a thickness of 50 μm as the first PET layer.

[0068] (2) Coating silicone oil layer:

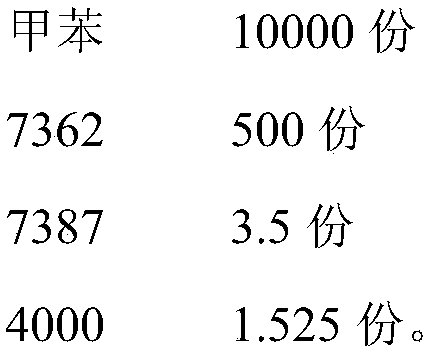

[0069] The composition of the silicone oil layer is as follows:

[0070]

[0071]Ingredients steps:

[0072] a. First weigh a certain amount of toluene, put it into a stainless steel bucket, calculate the required weight of 7362 according to the proportion, put it into the stainless steel bucket and stir it with a pneumatic mixer for 10 minutes.

[0073] b. Calculate the required weight of 7387 according to the proportion, put it into the ingredients stainless steel bucket, and stir for 20 minutes.

[0074] c. Calculate the required weight of 4000 according to the proportion, put it into the stainless steel bucket of ingredients, and stir for 10 minutes.

[0075] d. Coat the configured silicone oil on the corona surface of the first PET layer using a compound machine.

[0076] e. Production process p...

Embodiment 2

[0092] 2 million customer orders

[0093] (1) Choose a single-sided corona PET with a thickness of 50 μm as the first PET layer.

[0094] (2) Coating silicone oil layer:

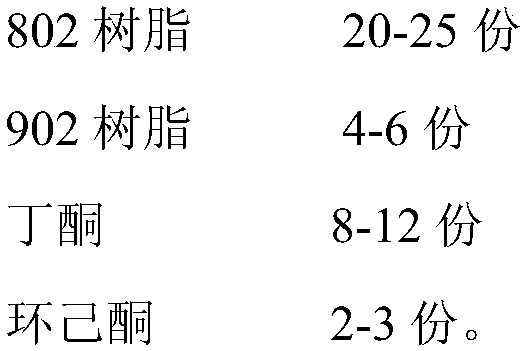

[0095] The composition of the silicone oil layer is as follows:

[0096]

[0097] Ingredients steps:

[0098] a. First weigh a certain amount of toluene, put it into a stainless steel bucket, calculate the required weight of 7362 according to the proportion, put it into the stainless steel bucket and stir it with a pneumatic mixer for 10 minutes.

[0099] b. Calculate the required weight of 7387 according to the proportion, put it into the ingredients stainless steel bucket, and stir for 20 minutes.

[0100] c. Calculate the required weight of 4000 according to the proportion, put it into the stainless steel bucket of ingredients, and stir for 10 minutes.

[0101] d. Coat the configured silicone oil on the corona surface of the first PET layer using a compound machine.

[0102] e. Production process ...

Embodiment 3

[0118] 3 million customer orders

[0119] (1) Choose a single-sided corona PET with a thickness of 50 μm as the first PET layer.

[0120] (2) Coating silicone oil layer:

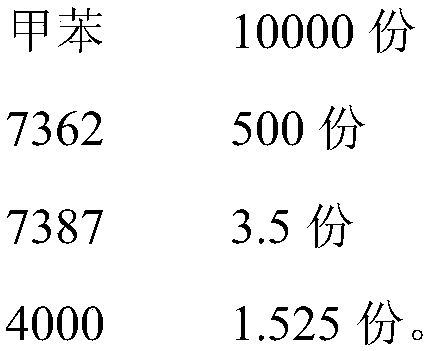

[0121] The composition of the silicone oil layer is as follows:

[0122]

[0123] Ingredients steps:

[0124] a. First weigh a certain amount of toluene, put it into a stainless steel bucket, calculate the required weight of 7362 according to the proportion, put it into the stainless steel bucket and stir it with a pneumatic mixer for 10 minutes.

[0125] b. Calculate the required weight of 7387 according to the proportion, put it into the ingredients stainless steel bucket, and stir for 20 minutes.

[0126] c. Calculate the required weight of 4000 according to the proportion, put it into the stainless steel bucket of ingredients, and stir for 10 minutes.

[0127] d. Coat the configured silicone oil on the corona surface of the first PET layer using a compound machine.

[0128] e. Production process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com