Clutch plate framework gluing system

A clutch and skeleton technology, applied in the coating, the device for coating liquid on the surface, the pretreatment surface, etc., can solve the problems of low work efficiency, uneven coating, etc., achieve simple structure, high coating efficiency, High quality glue application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Please refer to Figure 4 , A clutch sheet skeleton gluing system, including a clutch sheet skeleton gluing machine 1, a cooling conveyor belt 2 and a material receiving mechanism 3.

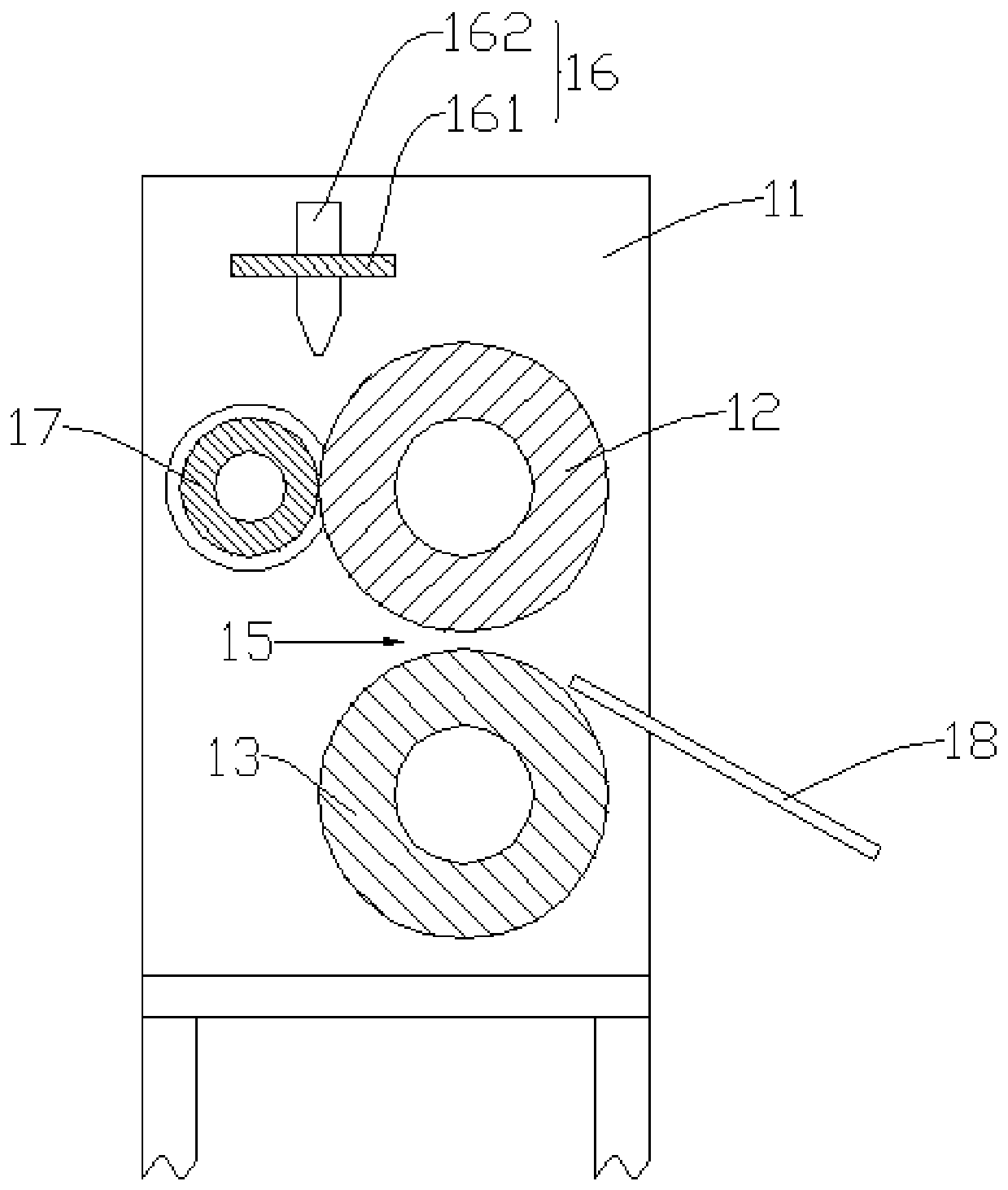

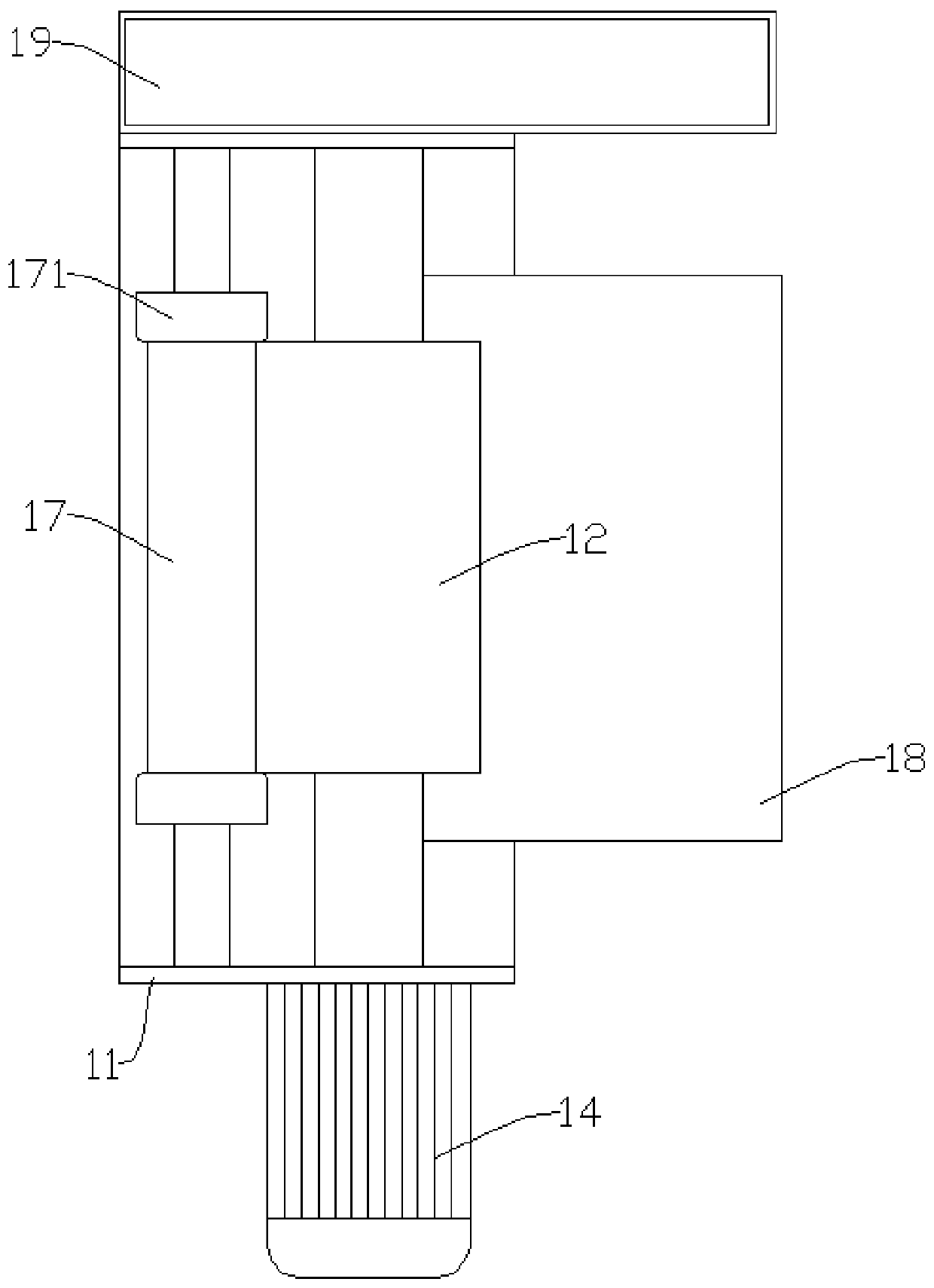

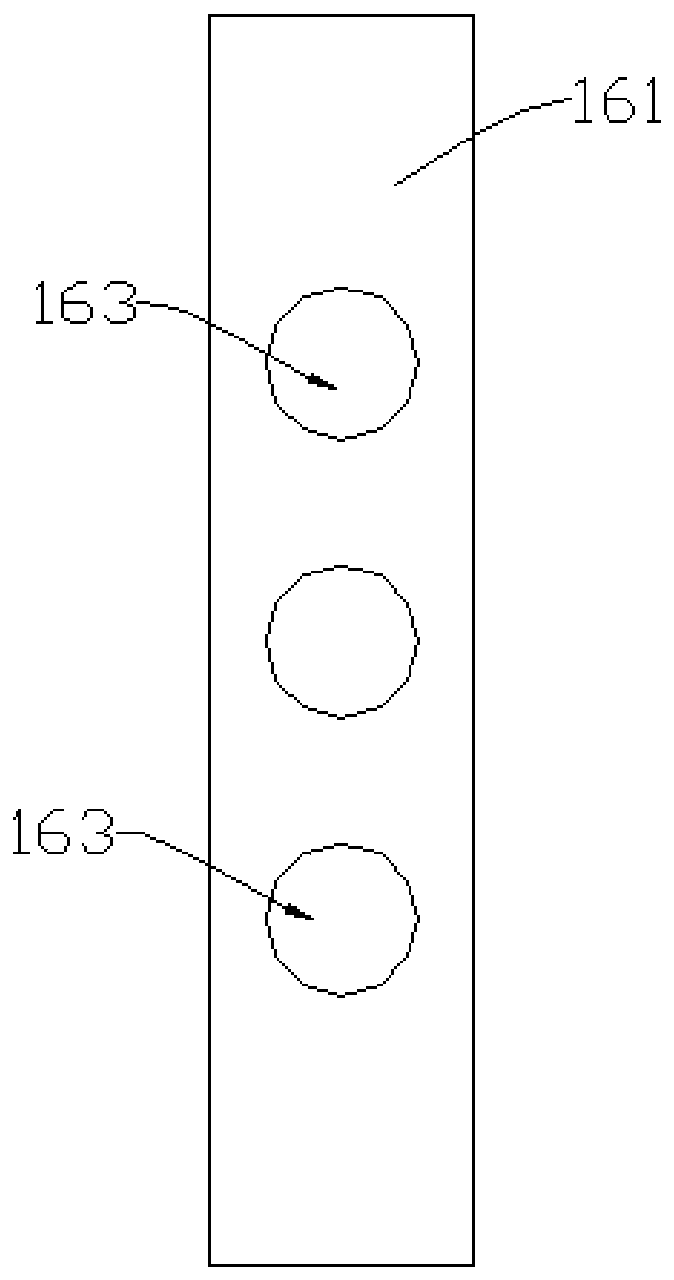

[0034] The clutch sheet skeleton gluing machine includes a frame 11, an upper roller 12 and a lower roller 13. The frame 11 is installed on a working platform. The upper roller 12 and the lower roller 13 are respectively mounted on the frame 11 and the upper roller can rotate around their central axis. 12 is located directly above the lower roller 13, the rotating power source of the upper roller 12 and the lower roller 13 is the rotary output mechanism 14. It should be noted that the rotary output mechanism 14 can be installed on the frame 11 or the work platform, and the output end of the rotary output mechanism 14 The upper roller 12 or the lower roller 13 can be connected, and the rotation speed of the rotating output mechanism 14 should be controlled within a reasonable range. It should ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com