Pole piece adhesive tape pasting mechanism

A gluing mechanism and gluing technology, applied in labeling machines, labeling, labeling, etc., can solve problems affecting the quality of gluing and easy foaming, and achieve the effect of improving the quality of gluing and avoiding foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The preferred embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings of this specification.

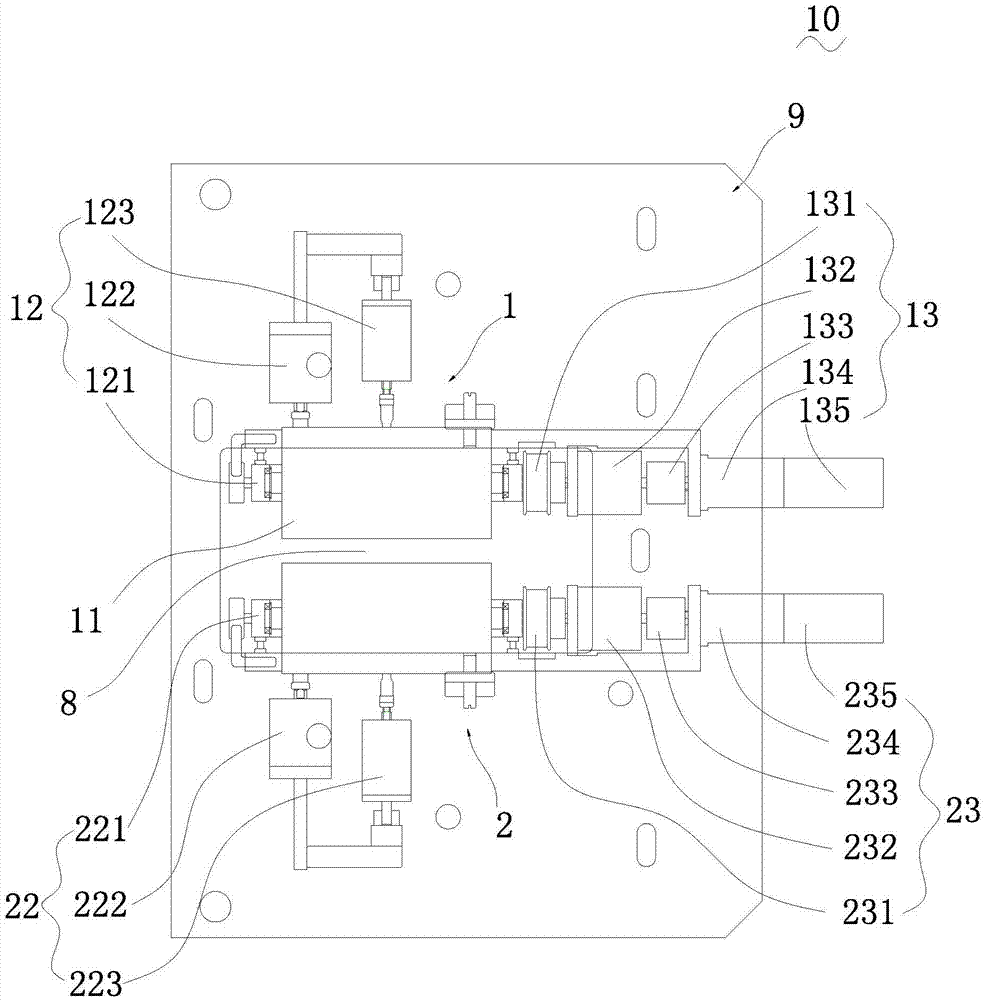

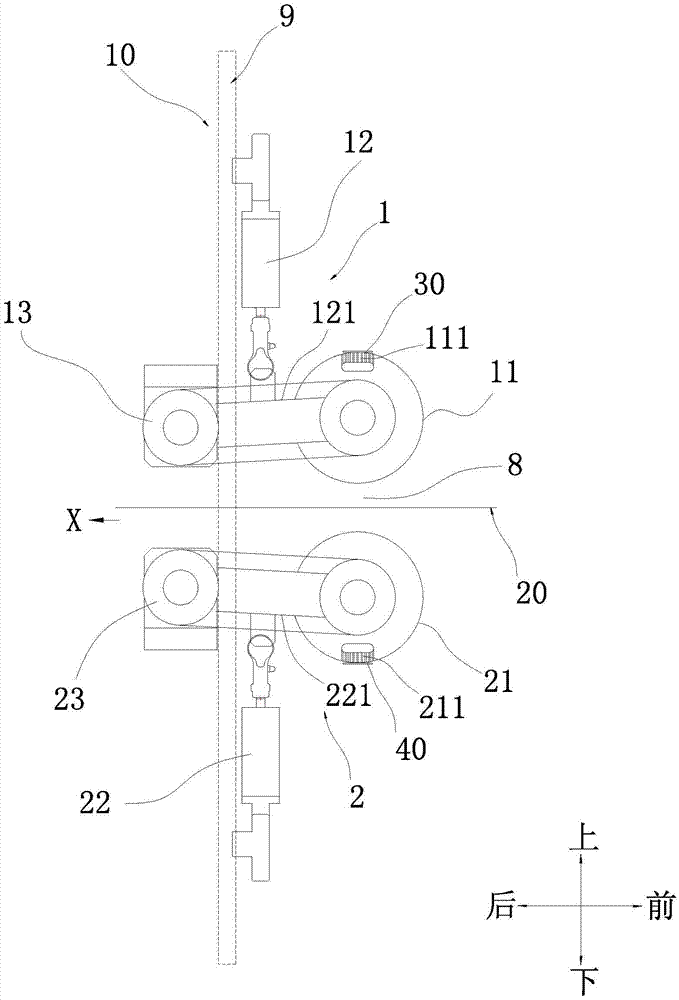

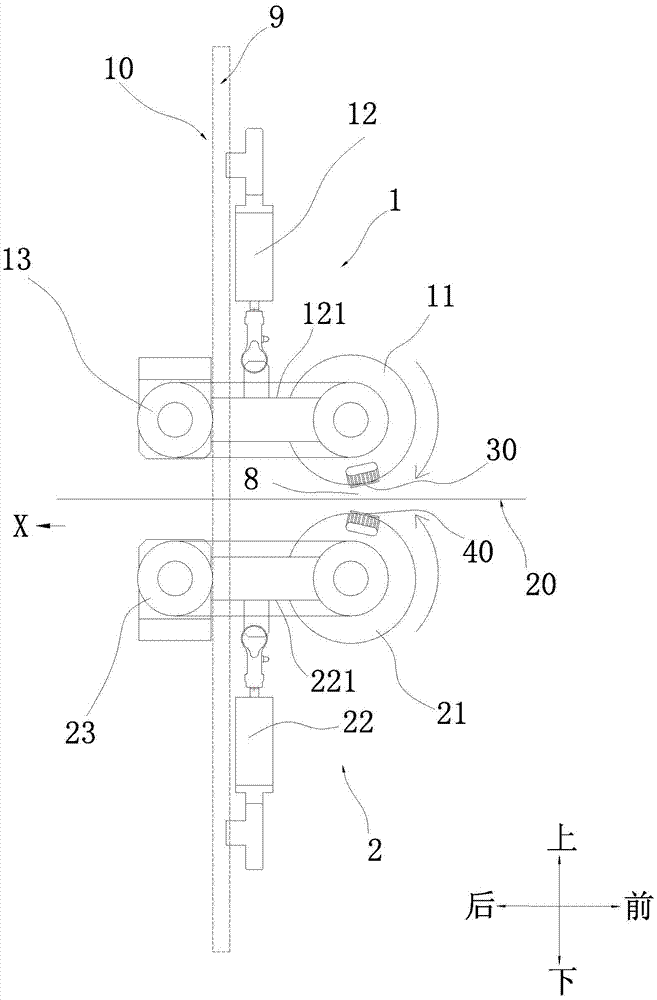

[0010] see Figures 1 to 2c , figure 1 It is a front view structural schematic diagram of an embodiment of the pole piece gluing mechanism of the present invention. Figures 2a to 2c It is a side-view structural schematic diagram of three working states of the pole piece gluing mechanism of the present invention, wherein Figure 2a It shows that the gluing roller is in the glue preparation position, Figure 2b It shows that the gluing roller is at the origin position, Figure 2c It shows that the gluing roller is in the gluing position. The present invention proposes a pole piece gluing mechanism 10 , which includes a first set of gluing unit 1 and a second set of gluing unit 2 that cooperate with each other. These two sets of gluing units 1 and 2 are installed on the same mounting plate 9 .

[0011] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com