Built-in direct-discharge type vapor-liquid phase change nozzle combination module

A direct-discharge, nozzle technology, applied in steam traps, injection devices, injection devices, etc., can solve the problems of inability to adjust the displacement, increase maintenance costs, waste of steam resources, etc., to improve service life and drainage accuracy, Ensure the effect of process temperature and process pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

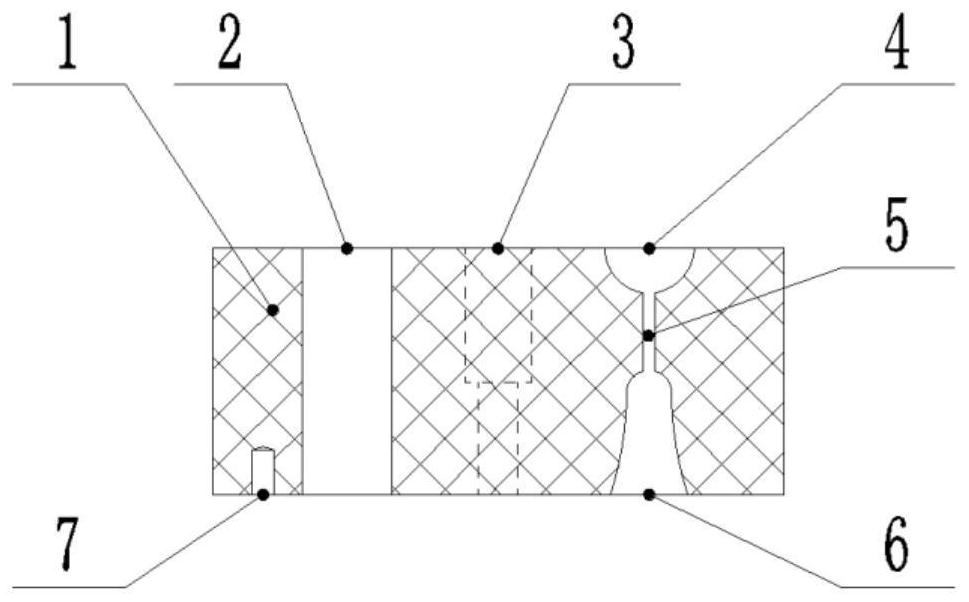

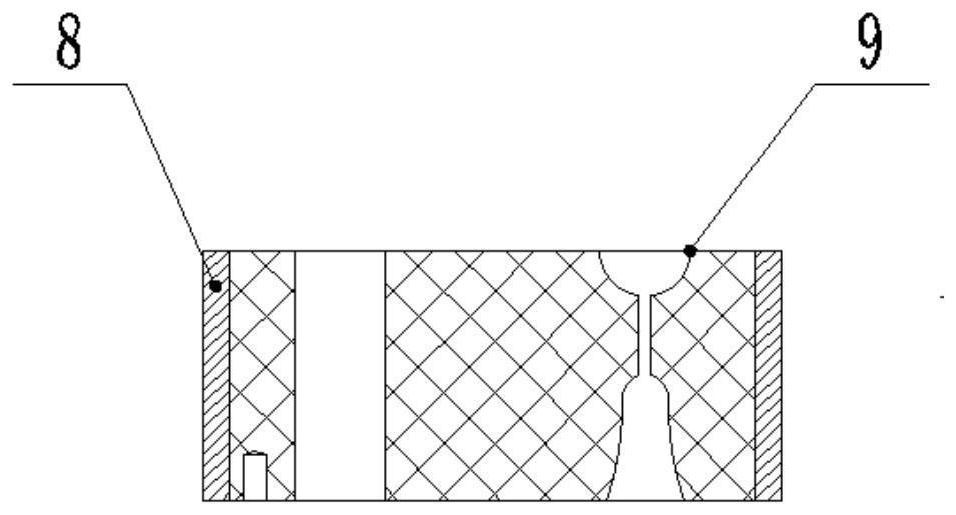

[0021] Such as Figure 1-Figure 2 As shown, the present invention provides a built-in in-line vapor-liquid phase change nozzle combination module, which includes a cylindrical module body 1 made of polymer material, and a through-hole structure with equal diameters is arranged on the module body 1. Straight through holes 2 and a plurality of nozzle through holes 9 arranged in the circumferential direction, and a plurality of module fixing screw holes 3 are provided on the edge of the module body 1 for positioning and connection between parts connected to the module body 1 ; The nozzle through hole 9 includes a bowl-shaped groove 4 of a hemispherical structure, a throat measuring hole 5, and a liquid outlet jet channel 6 of a conical structure with an open lower end in the vertical direction from top to bottom. The throat measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com