Novel multifunctional three-dimensional conduction fabric, preparation method thereof and application of fabric

A conductive fabric, multi-functional technology, applied in the field of textiles, to achieve the effect of reducing transmittance, good space mesh overall effect, and reducing re-pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

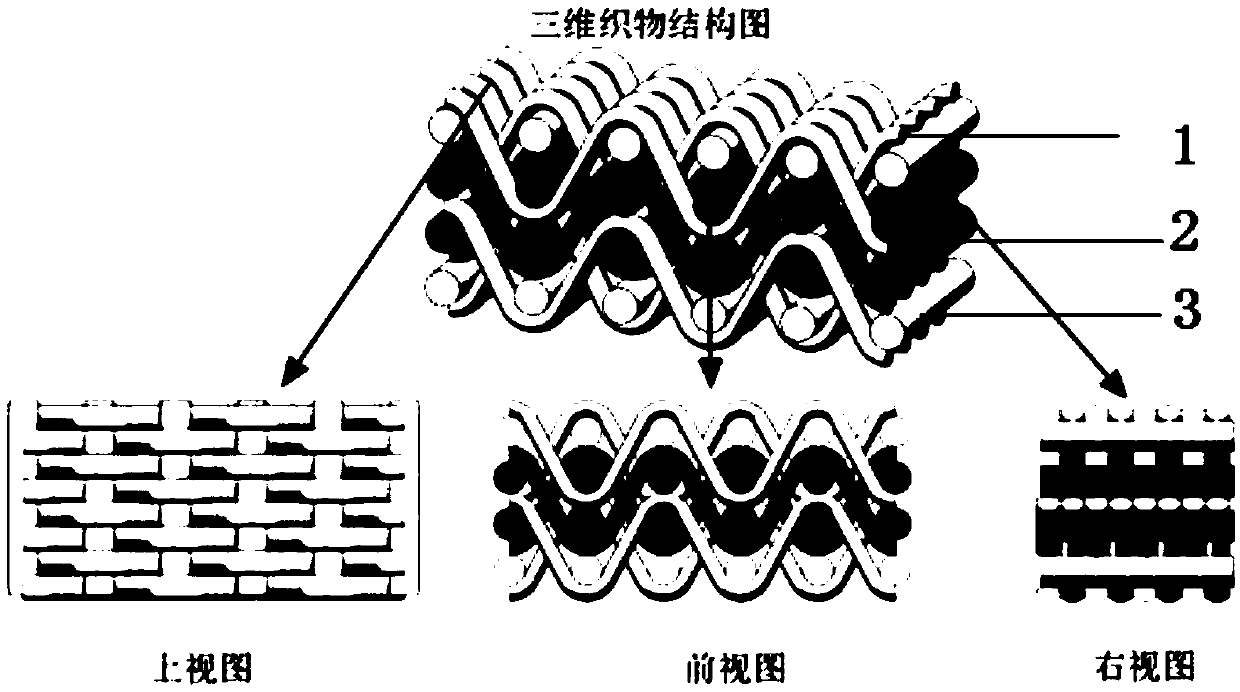

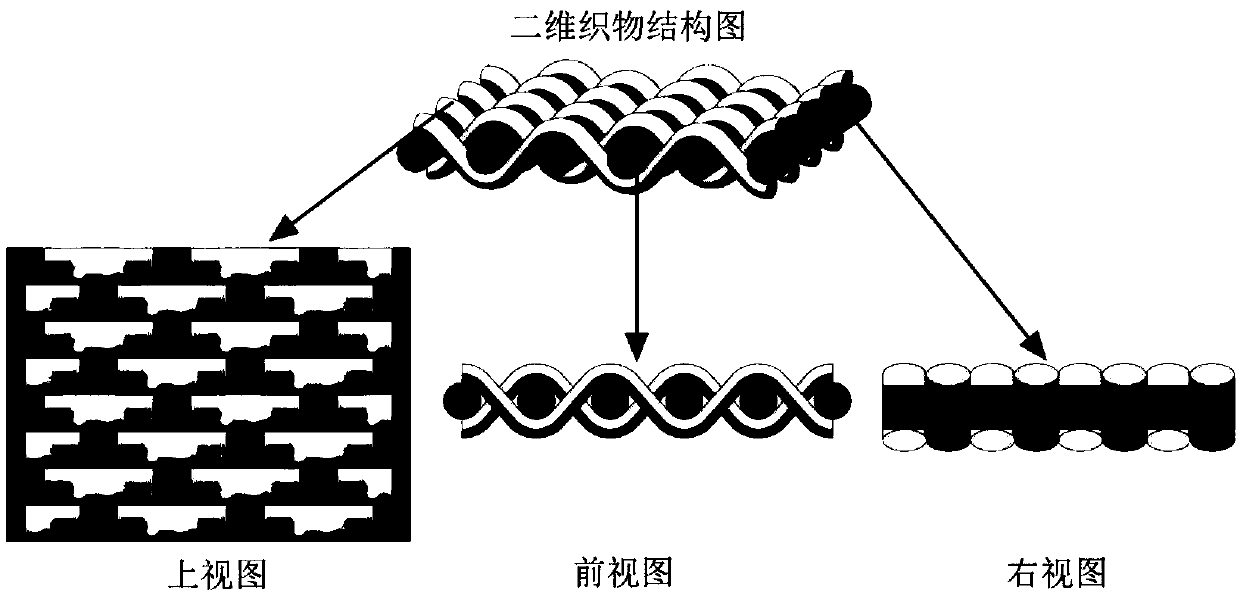

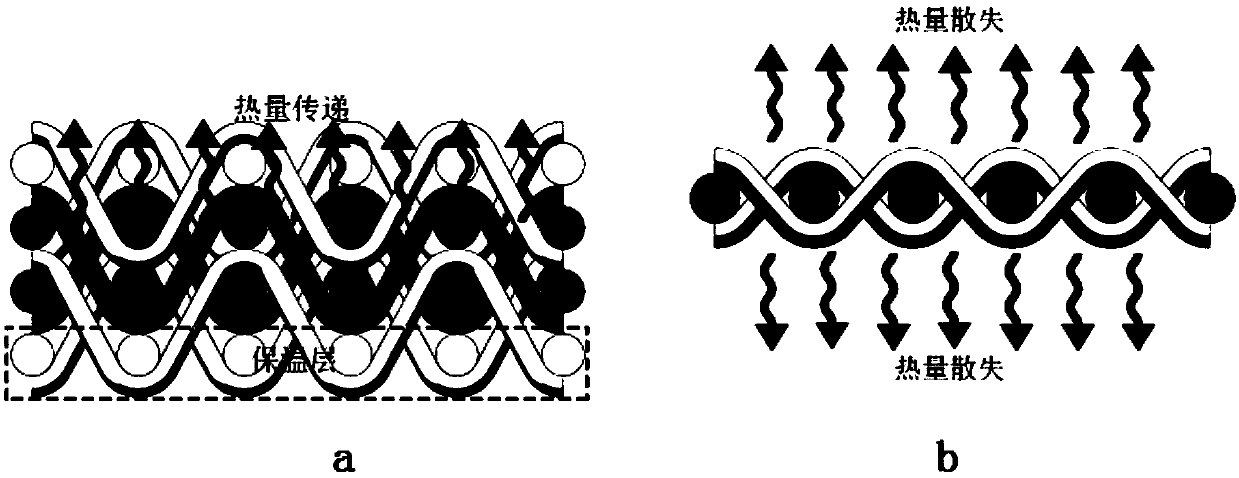

[0073] figure 1 As shown, a new multifunctional three-dimensional conductive fabric, from top to bottom is the appearance layer 1, the functional conductive layer 2 and the fabric protection layer 3, and the above three layers are formed by interweaving warp yarns and weft yarns or binding yarns. made. The appearance layer 1 is a fabric composed of one or more layers of warp yarns and one or more layers of weft yarns. The functional conductive layer 2 is a fabric composed of weft yarns and warp yarns, and the number of layers is adjusted according to application requirements. The fabric protection layer 3 is made of one or more layers of warp yarns and one or more layers of weft yarns.

[0074] The above-mentioned three layers are formed by laying the warp system in the thickness direction at a certain buckling change angle into the vertically arranged weft system, tying and weaving them into one body, or by binding and connecting the warp system and the weft system through...

Embodiment 2

[0086] A new multi-functional three-dimensional conductive fabric, from top to bottom is an appearance layer 1, a functional conductive layer 2 and a fabric protection layer 3, and the above three layers are formed by interweaving warp yarns and weft yarns or bundling yarns. The appearance layer 1 is a fabric composed of multiple layers of warp yarns and multiple layers of weft yarns. The functional conductive layer 2 is a fabric composed of weft yarns and warp yarns, and the number of layers is adjusted according to application requirements. The fabric protection layer 3 is made of multiple layers of warp yarns and multiple layers of weft yarns.

[0087] The above-mentioned three layers are formed by laying the warp system in the thickness direction at a certain buckling change angle into the vertically arranged weft system, tying and weaving them into one body, or by binding and connecting the warp system and the weft system through the binding yarn passing through the thick...

Embodiment 3

[0093] A new multi-functional three-dimensional conductive fabric, from top to bottom is an appearance layer 1, a functional conductive layer 2 and a fabric protection layer 3, and the above three layers are formed by interweaving warp yarns and weft yarns or bundling yarns. The appearance layer 1 is a fabric composed of multiple layers of warp yarns and multiple layers of weft yarns. The functional conductive layer 2 is a fabric composed of weft yarns and warp yarns, and the number of layers is adjusted according to application requirements. The fabric protection layer 3 is made of multiple layers of warp yarns and multiple layers of weft yarns.

[0094] The above-mentioned three layers are formed by laying the warp system in the thickness direction at a certain buckling change angle into the vertically arranged weft system, tying and weaving them into one body, or by binding and connecting the warp system and the weft system through the binding yarn passing through the thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com