Venturi mixer with drainage function

A Venturi mixer and function technology, applied in fluid mixers, mixers, mixing methods, etc., can solve the problems of air intake blockage, poor gas intake, affecting air-fuel ratio control of in-cylinder combustion, etc. Reduced airflow collision loss, reduced impact, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

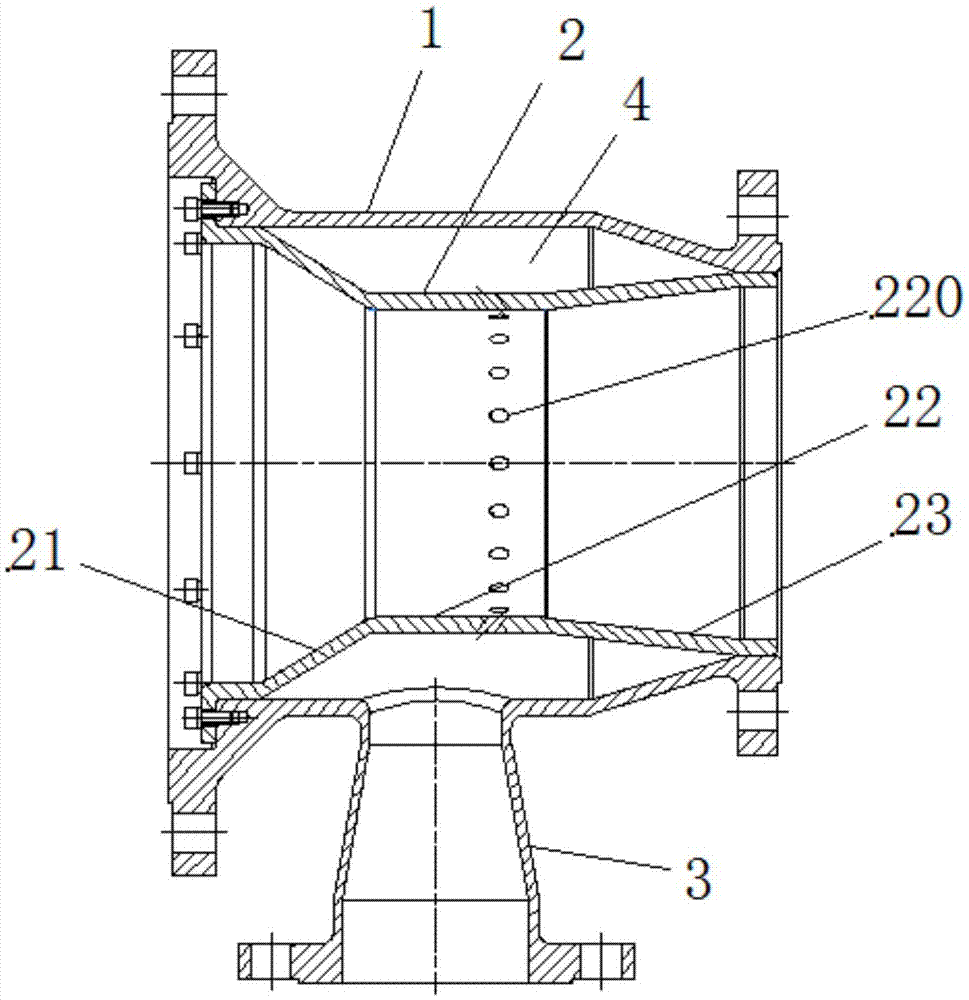

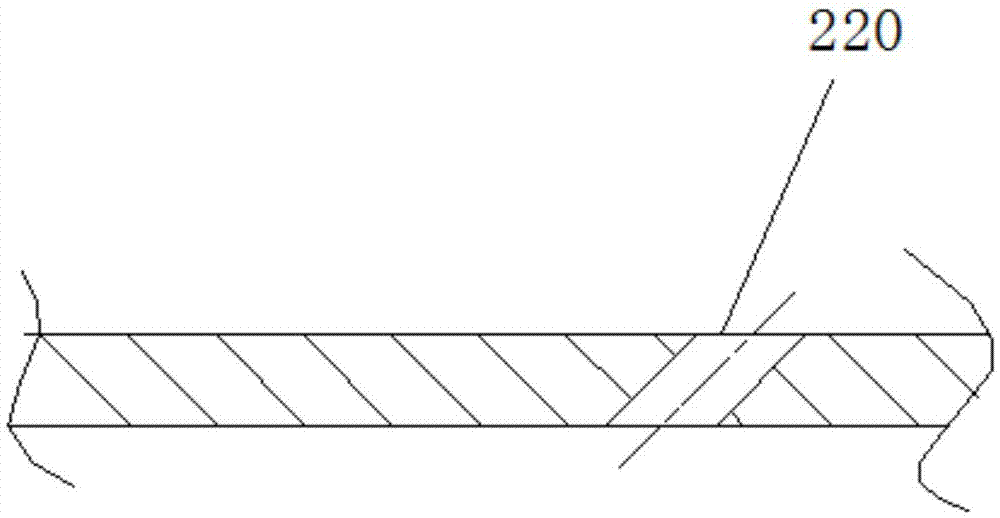

[0022] Such as figure 1 and figure 2 The shown Venturi mixer with drainage effect includes an outer pipe 1, an inner pipe 2 and an air inlet 3 vertically arranged on the outer pipe 1, the inner pipe 2 is arranged inside the outer pipe 1, and the inner pipe 2 includes a constriction The mouth section 21, the throat section 22 and the flaring section 23, the necking section 21, the throat section 22 and the flaring section 23 are smooth circular arc transition connections, and the necking angle of the necking section 21 is 25° ~35°, the flaring angle of the flaring section 23 is 10°-25°, the flaring angle is smaller than the shrinking angle, which can ensure that the air passes through the throat section 22 to accelerate to form a negative pressure zone, which can drain the gas effect.

[0023] The inlet end of the outer pipe 1 and the inner pipe 2 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com