An environment-friendly efficient flue gas spraying and dust removing device

A dust removal device and flue gas technology, which is applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems that dust particles are easy to cause smog, affect respiratory safety and physical health, etc., and improve the efficiency and effectiveness of employees , improve work efficiency and effect, and facilitate the effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

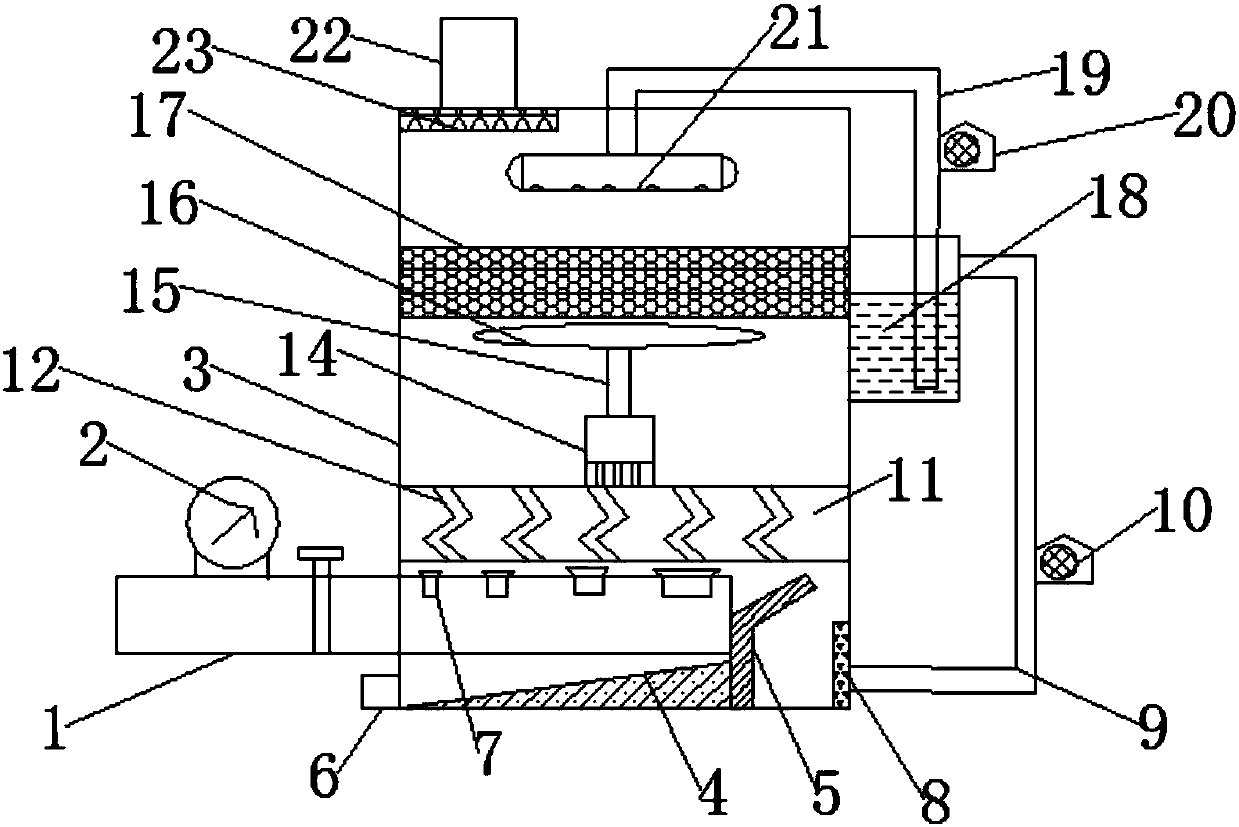

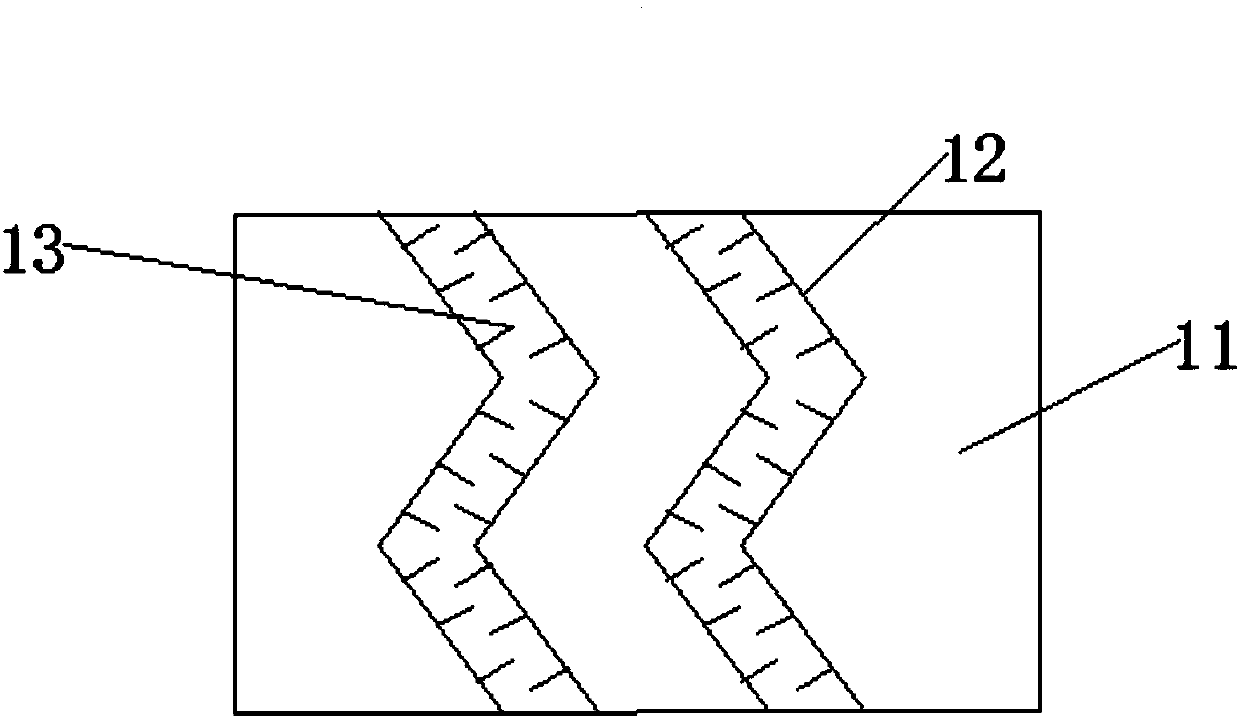

[0017] see Figure 1-2 , an environment-friendly flue gas high-efficiency spraying and dust removal device, comprising an intake pipe 1, a treatment box 3, a partition 5, a sewage pipe 6, a return pipe 9, an air filter plate 11, vent holes 12, bristles 13, a rotating shaft 15, and stirring blades 16. Active carbon filter plate group 17, water tank 18, water spray pipe 19, spray discharge 21 and air outlet pipe 22, the bottom side wall of the treatment box 3 is communicated with the intake pipe 1, and the gas flow meter 2 is installed on the intake pipe 1, One end of the intake pipe 1 is connected to the external flue gas pipe, and the upper side wall of the other end of the intake pipe 1 is uniformly provided with a plurality of one-way valves 7, and the one-way valves 7 are arranged inside the processing box 3, and the apertures of the one-way val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com