Gas distributor for uniform gas emission

A gas distributor and gas distribution technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the uneven distribution of gas flow field and temperature field of CVD reactor, which is difficult to meet the needs of film growth, Increased design requirements for uniform temperature field, etc., to achieve the effects of easy assembly and maintenance, uniform growth, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

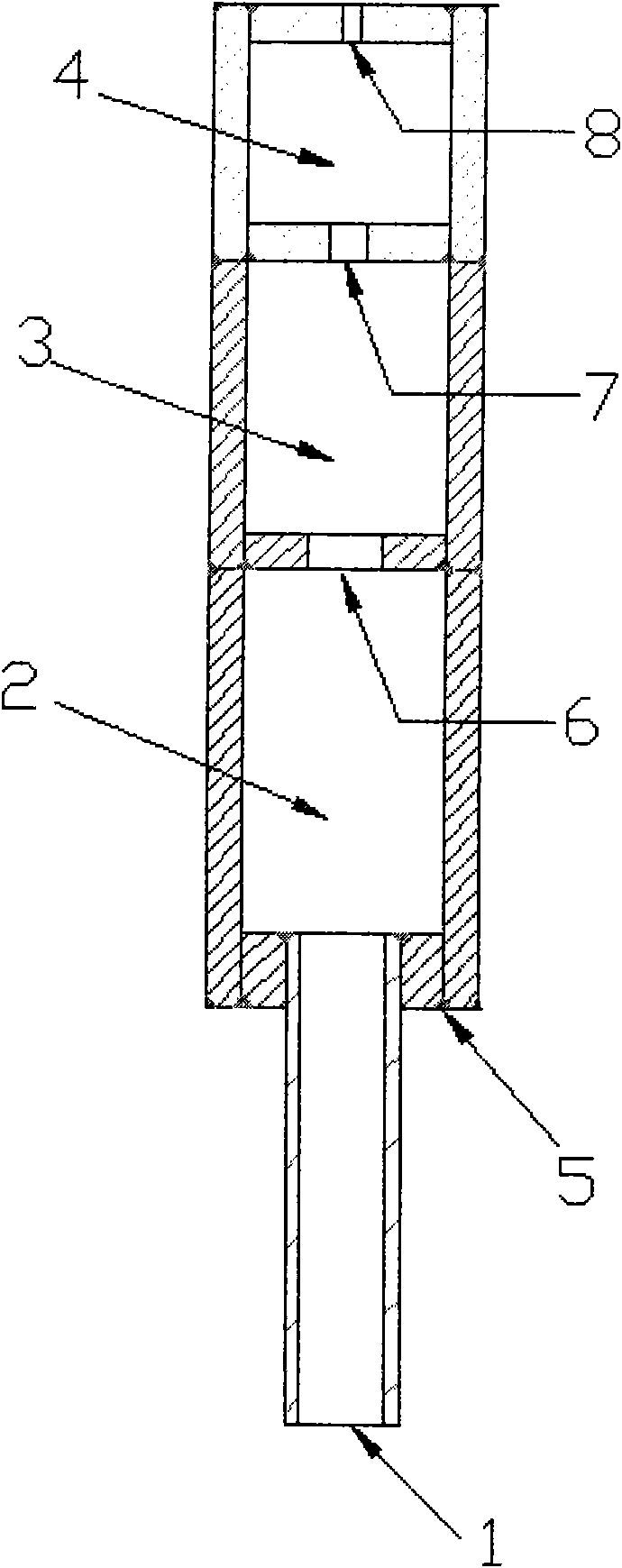

[0029] Example 1 The gas distributor with uniform gas outlet is mainly used in the reactor of metal-organic chemical vapor deposition, and its structure is as follows figure 1 As shown, that is, it is composed of a 1 / 4 standard air intake pipe 1 and three layers of gas distribution chambers 2, 3, 4 vertically welded, and several welding spots 5 are arranged between adjacent gas distribution chambers. The inscribed circle radii of the above-mentioned gas distribution chambers are all 150 mm, and the cavity heights of the first to third layers of gas distribution chambers 2, 3, and 4 are 20 mm, 15 mm, and 10 mm, respectively. 20 gas distribution holes 6 are evenly distributed on the connecting wall of the first layer between the first and second layers of gas distribution chambers 2 and 3, with a diameter of 4mm; the second layer between the second and third layers of gas distribution chambers There are 30 air distribution holes 7 evenly distributed on the connecting wall, with ...

Embodiment 2

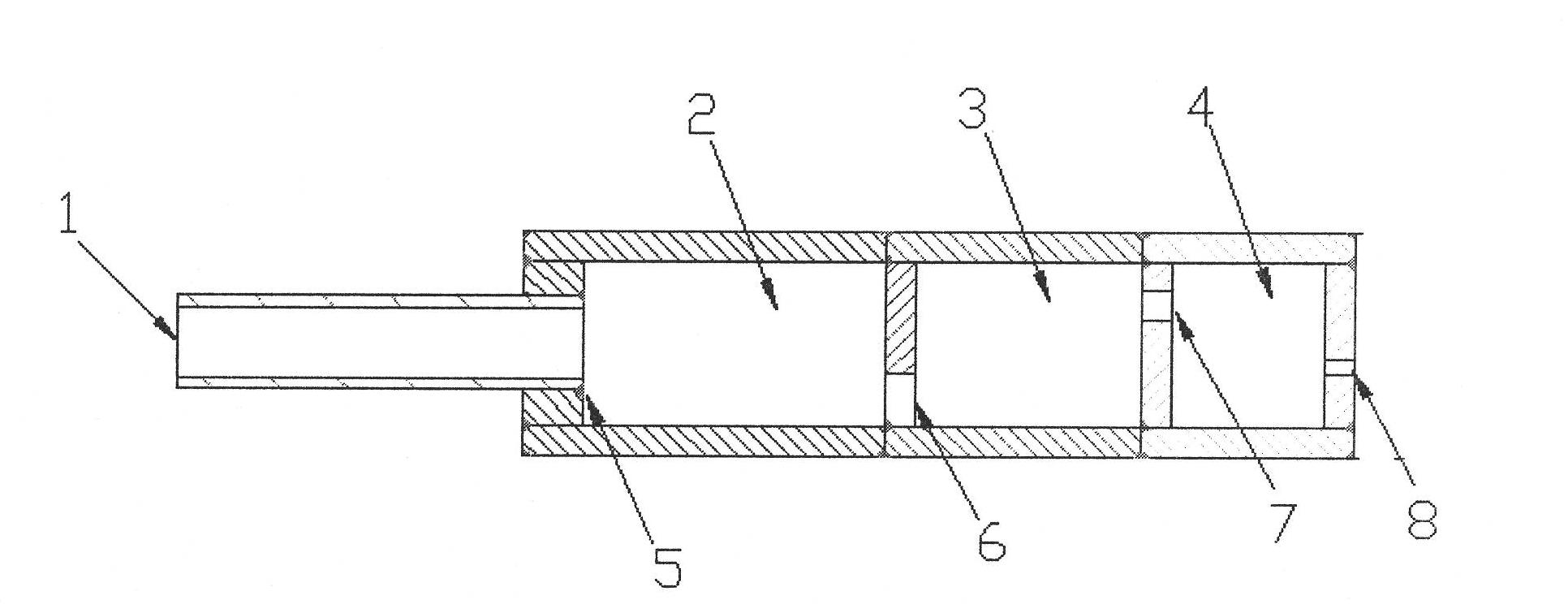

[0031] Example 2 as figure 2 As shown, the structure of the gas distributor for uniform gas outlet in this embodiment is similar to that of Embodiment 1, but it is mainly composed of an inlet pipe 1 and three layers of gas distribution chambers 2, 3, 4 welded in the horizontal direction, adjacent gas distribution Several welding spots 5 are arranged between the cavities. The calibers of the above-mentioned gas distribution chambers are the same, but the lengths of the gas distribution chambers 2, 3 and 4 in the first to third layers are successively reduced. A number of gas distribution holes 6 are distributed on the first layer connecting wall between the first and second layer gas distribution chambers 2 and 3; Air holes 7; a number of air distribution holes 8 are distributed on the connecting wall of the third layer; and the diameters of the air distribution holes 6-8 decrease in turn. In addition, in the direction of air flow, the air distribution holes 6, 7, and 8 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com