Gas-solid mixed heat carrier quick pulverized coal pyrolysis process and device

A technology of gas-solid mixing and pulverized coal, which is applied in the petroleum industry, special forms of dry distillation, coking ovens, etc., can solve the problems of small processing scale, difficulty in recycling coal tar, short operation period, etc., and achieve stable pyrolysis reaction temperature and The effect of pyrolysis oil gas temperature, ensuring smooth operation of the process, and reducing dust content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

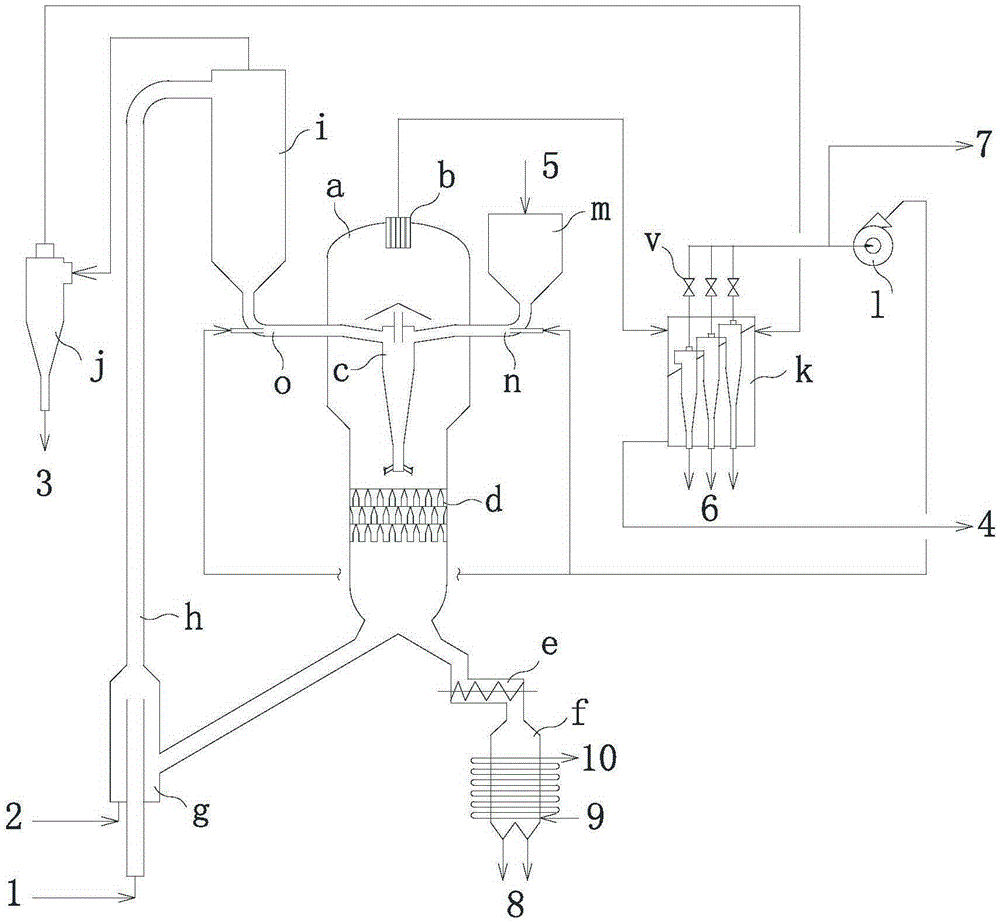

[0069] see figure 1 , a gas-solid mixed heat carrier rapid pulverized coal pyrolysis process based on the device, comprising the following steps:

[0070] (1) Send the dried raw coal 5 with a particle size of 0.2 to 8mm and a temperature of 150°C into the dry raw coal bunker m, and the dried pulverized coal in the dried raw coal bunker m enters the L-shaped coal from the bottom outlet. The dry raw coal control valve merges with the pyrolysis oil and gas at 600°C from the high-temperature centrifugal fan 1, and enters the swirl mixer built in the middle of the pyrolysis reactor, and adjusts the drying with the flow rate of the pyrolysis oil and gas. Raw coal 5 flow rate.

[0071] (2) The high-temperature semi-coke from the simple separator i enters the L-shaped high-temperature semi-coke control valve o from the bottom discharge port and merges with the pyrolysis oil gas with a temperature of 600 ° C from the high-temperature centrifugal fan l, and the pyrolysis oil gas Under...

Embodiment 2

[0079] see figure 1 , a gas-solid mixed heat carrier rapid pulverized coal pyrolysis process, comprising the following process steps:

[0080] (1) Dry and sieve the mined or purchased raw pulverized coal, or select the pulverized coal washed in the coal washing plant for drying. The dried raw coal 5 has a particle diameter of 0.2-8 mm and a temperature of 130° C., and is sent into the dry raw coal bunker m. The dry pulverized coal in the dry raw coal bunker m enters the L-shaped dry raw coal control valve n from the bottom outlet, and merges with the pyrolysis oil and gas at 400°C from the high-temperature centrifugal fan l, and the drying is adjusted by the flow rate of the pyrolysis oil and gas. The flow rate of the raw coal 5 enters the swirl mixer c built in the middle of the pyrolysis reactor a.

[0081] (2) The high-temperature semi-coke from the simple separator i enters the L-shaped high-temperature semi-coke control valve o from the bottom outlet, and merges with th...

Embodiment 3

[0089] Select Shenmu coal, 0.2-8mm, 140°C dry pulverized coal 5 treated by a vibrating fluidized bed dryer as raw material, and send it into the dry raw material coal bunker m. The dry pulverized coal 5 in the dry raw coal bunker m enters the L-shaped dry raw coal control valve n from the bottom outlet, and merges with the 450°C pyrolysis oil and gas from the high-temperature centrifugal fan l, and is adjusted by the flow rate of the pyrolysis oil and gas The flow of dry raw coal 5 enters the swirl mixer c built in the middle of the pyrolysis reactor a. The high-temperature semi-coke from the simple separator i enters the L-shaped high-temperature semi-coke control valve o from the bottom outlet, and merges with the pyrolysis oil gas from the high-temperature centrifugal fan l, and adjusts the flow rate of the high-temperature semi-coke according to the flow rate of the pyrolysis oil gas flow, and enter the swirl mixer c built in the middle of the pyrolysis reactor a. Dry pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com