Air inlet structure of electric propulsion engine

An air intake structure and engine technology, which is applied to machines/engines, mechanical equipment, thrust reversers, etc., can solve the problems of reduced engine body volume and complicated engine propellant supply, and achieve the effect of compact sealing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

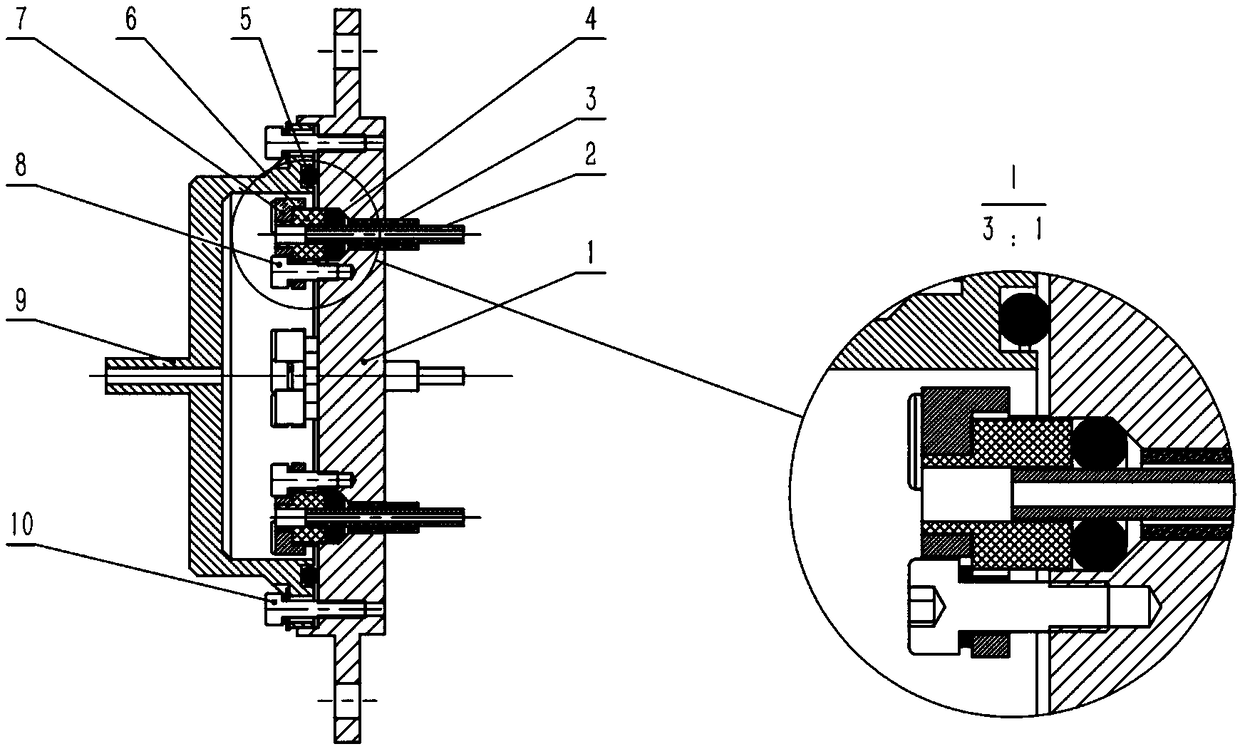

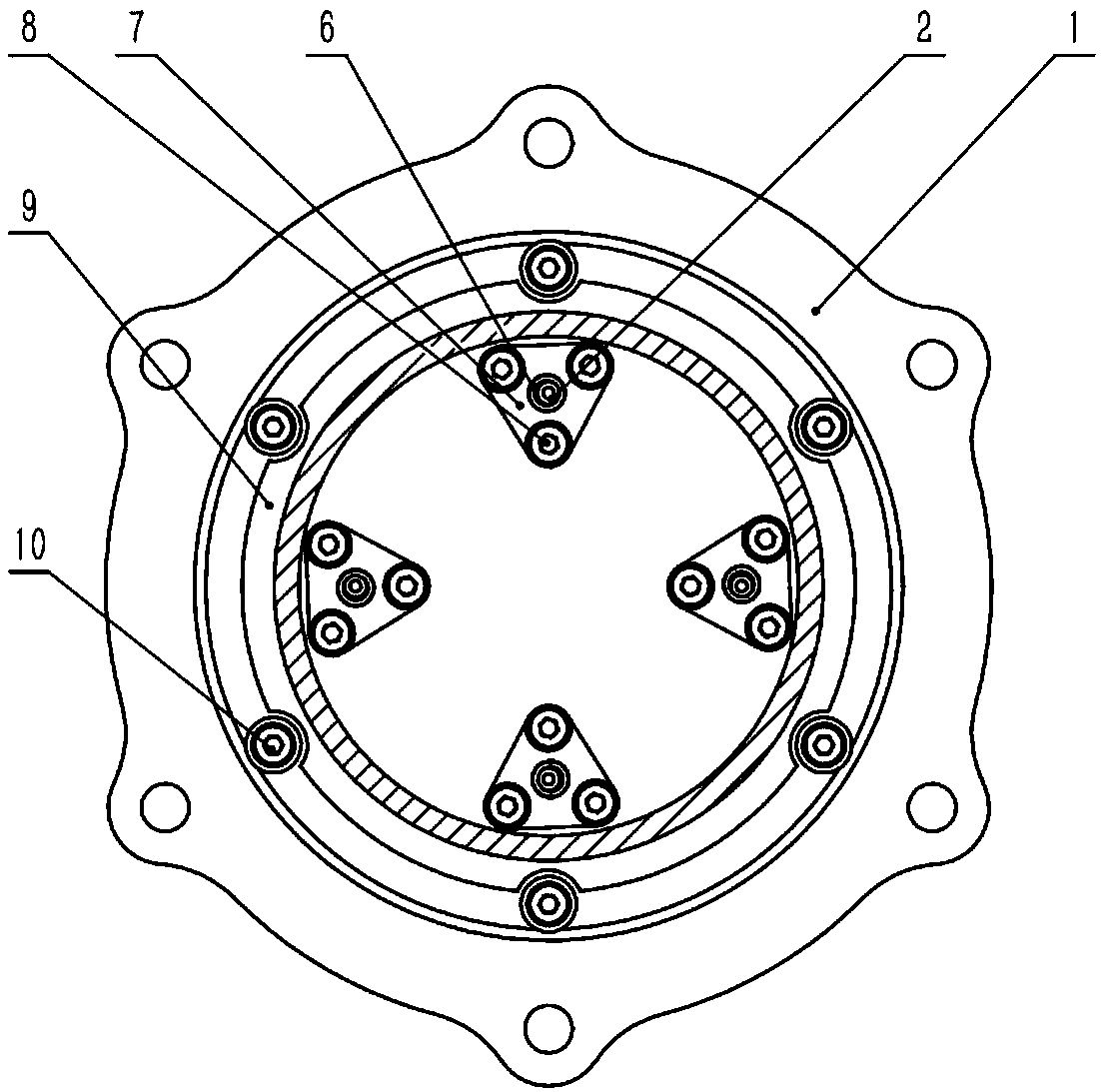

[0019] Attached below Figure 1~2 Specific embodiments of the present invention will be described.

[0020] The present invention is an electric propulsion engine air intake structure, the main components include engine body flange 1, gas distributor pipeline 2, insulating ceramic tube 3, gas distributor pipeline-sealing ring 4, air intake cavity-sealing ring 5. Gas distributor pipeline-ceramic terminal 6, gas distributor pipeline-press sheet 7, gas distributor pipeline-fastening bolt 8, inlet flange 9, connecting bolt 10.

[0021] combine figure 1 , taking the engine body flange 1 as a reference, insert four insulating ceramic tubes 3 from the right side into four 4mm small holes on the engine body flange 1, and the left end surface of the insulating ceramic tube 3 is connected to the engine body flange 1 Align the cone edges.

[0022] combine figure 1 , Insert the four gas distributor pipelines 2 into the four insulating ceramic tubes 3 from the right side, and the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com