Pressure-resistant injection head

An injection head, pressure-resistant technology, applied in the direction of pipes/pipe joints/fittings, damage protection, pipeline anti-corrosion/rust protection, etc. The effect of sealing and improving sealing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention provides a pressure-resistant injection head to solve the technical problem that the injection head is not resistant to high pressure in the prior art.

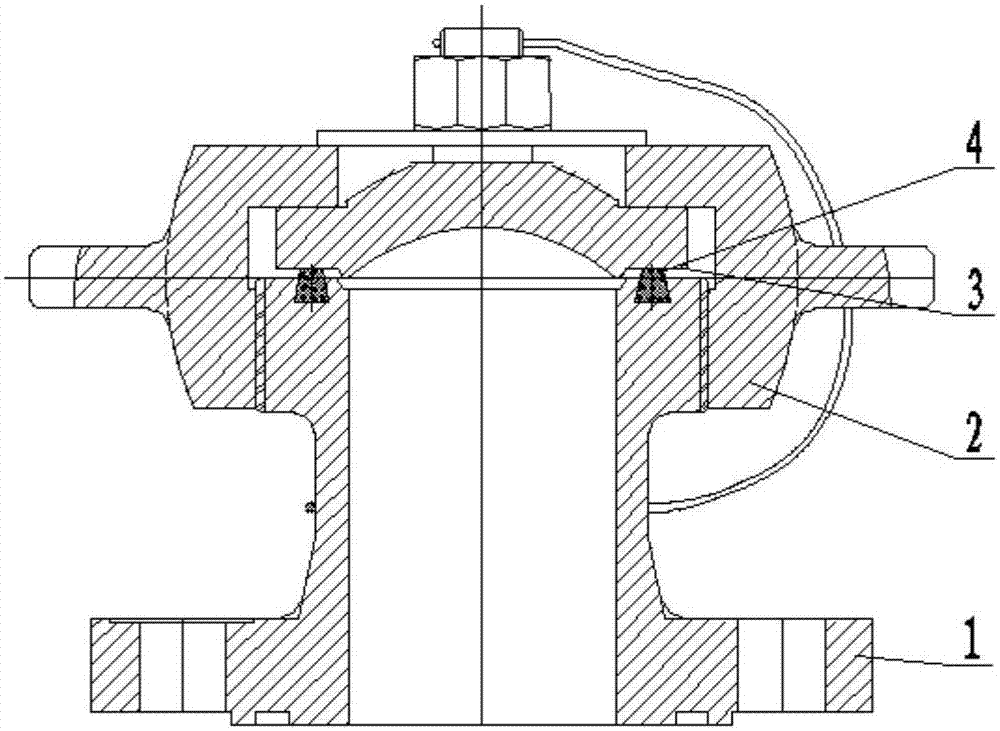

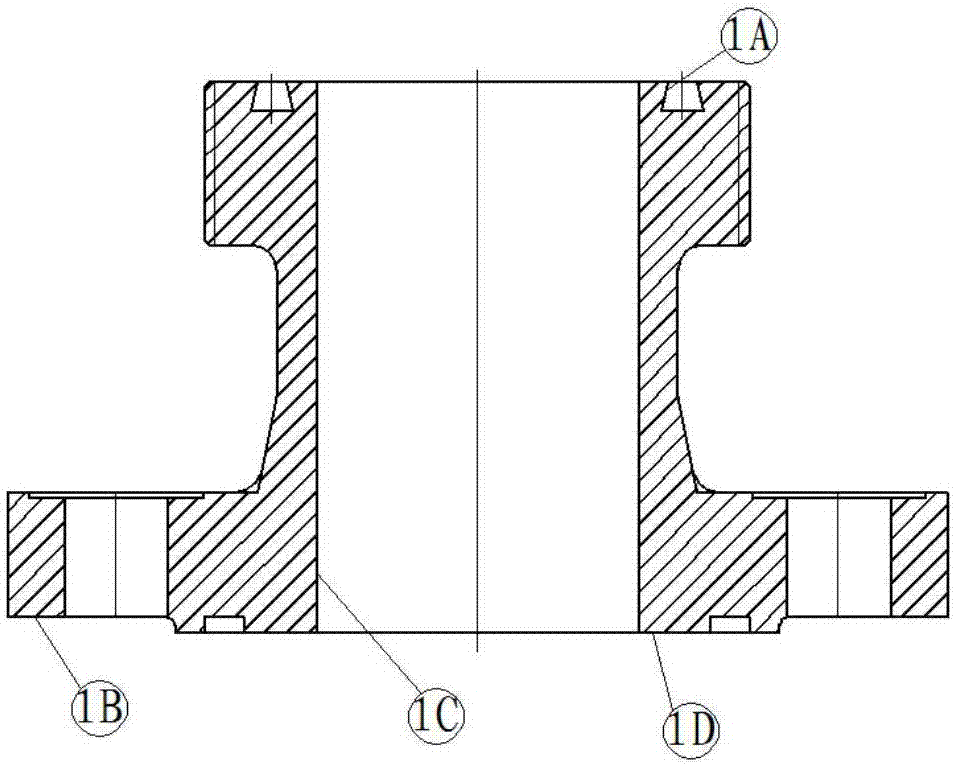

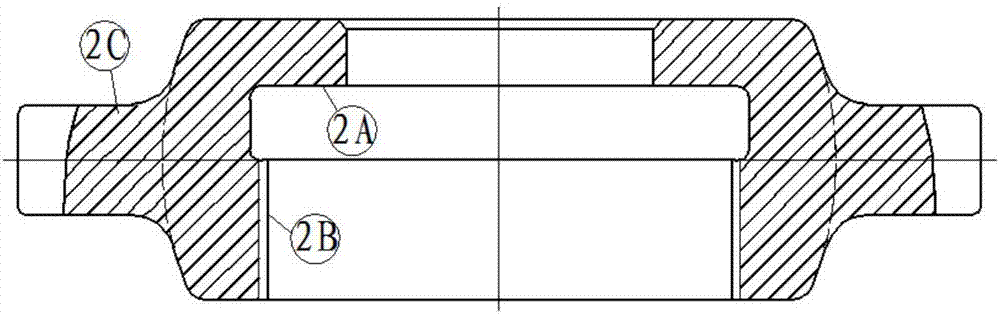

[0021] The general idea of the technical solution of the present invention is to provide a new pressure-resistant injection head with high pressure resistance, corrosion resistance, high sealing reliability and long life. The pressure-resistant injection head adopts a flat soft-sealed structure, which is composed of a body 1, a gland nut 2, a plug core 3 and a sealing washer 4. It has a simple structure, tight connection, and strong pressure resistance.

[0022] In order to better understand the technical solution of the present invention, the technical solution of the present invention will be described in detail below through the accompanying drawings and specific examples. It should be understood that the embodiments of the present invention and the specific features in the examples are detailed descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com