Shaft seal method of screw rotor automatic seal of impeller pump

A self-sealing, impeller-type technology, applied to non-variable pumps, components of pumping devices for elastic fluids, pumps, etc., can solve problems such as failure of dynamic sealing, complex manufacturing process, and various structural designs. To achieve the effect of compact sealing structure, reducing consumption cost and widening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

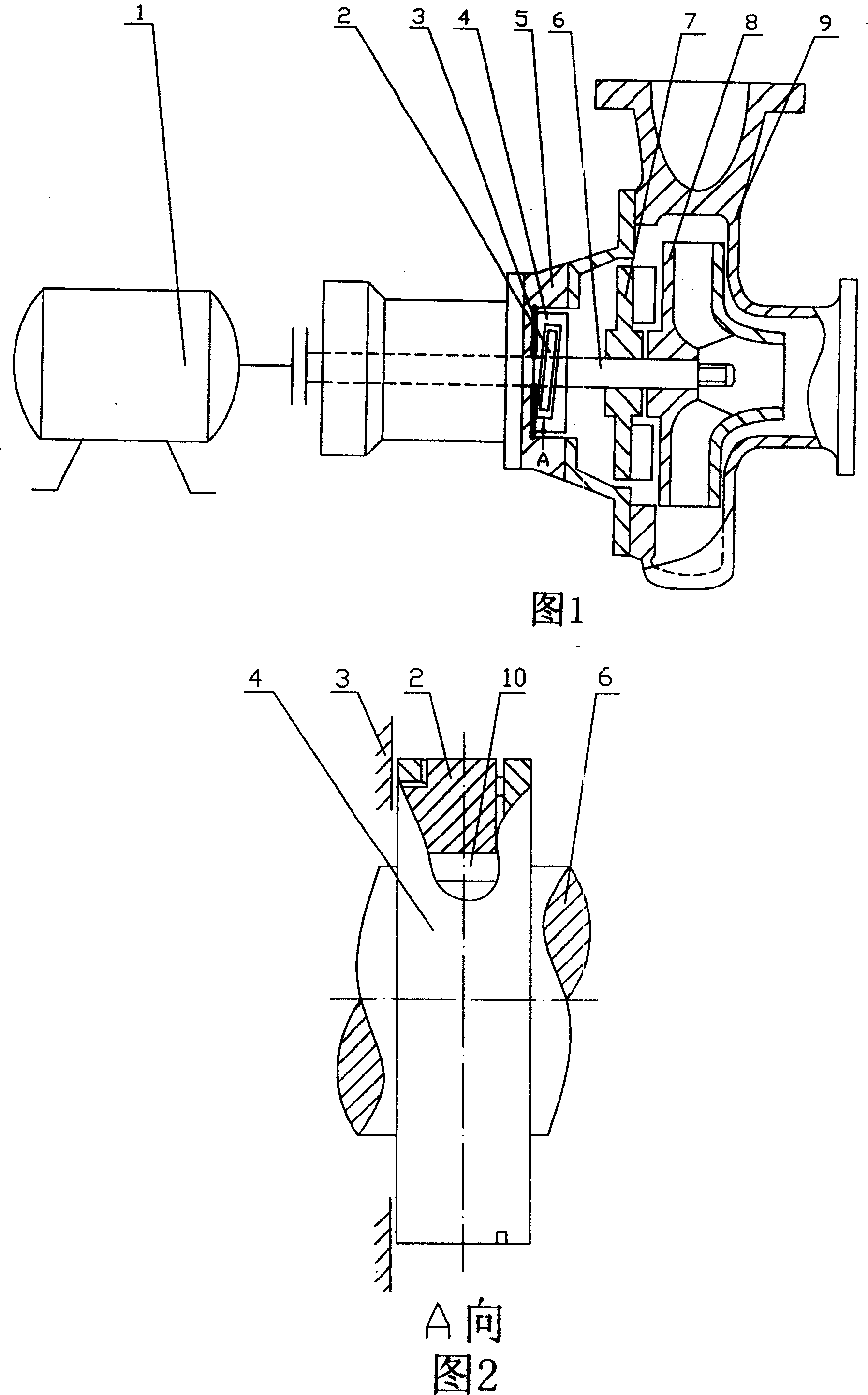

[0017] Shown in Fig. 1, 2 is one of embodiment of the present invention, is the impeller type centrifugal pump of application single suction port of the present invention, the impeller type centrifugal pump of the single suction port of a helical rotor automatic sealing device is housed on the pump shaft 6, comprises The impeller centrifugal pump composed of pump body 9, pump cover 5, pump shaft 6, main and auxiliary impellers 8 and 7 made of corrosion-resistant alloy steel, and motor 1 is characterized in that it is connected with the shaft sealing point in the impeller centrifugal pump 9 body Corresponding to the sealing end face 3, the screw rotor automatic sealing device composed of the active and driven screw rotors 2, 4 and key 10 made of corrosion-resistant alloy steel is installed on the 6th section of the pump shaft. Corroded rubber sealing layer, the automatic sealing device can rely on the generated inertia force during the whole process of centrifugal pump operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com