Continuous sludge thermo-hydrolysis device and use method thereof

A technology for thermal hydrolysis and sludge, applied in chemical instruments and methods, mixers with rotary stirring devices, dewatering/drying/concentrating sludge treatment, etc., can solve the problem of large-scale application of sludge thermal hydrolysis process , insufficient stability, low treatment efficiency, etc., to achieve stable thermal hydrolysis effect of sludge, strong sludge adaptability, and sufficient sludge hydrolysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

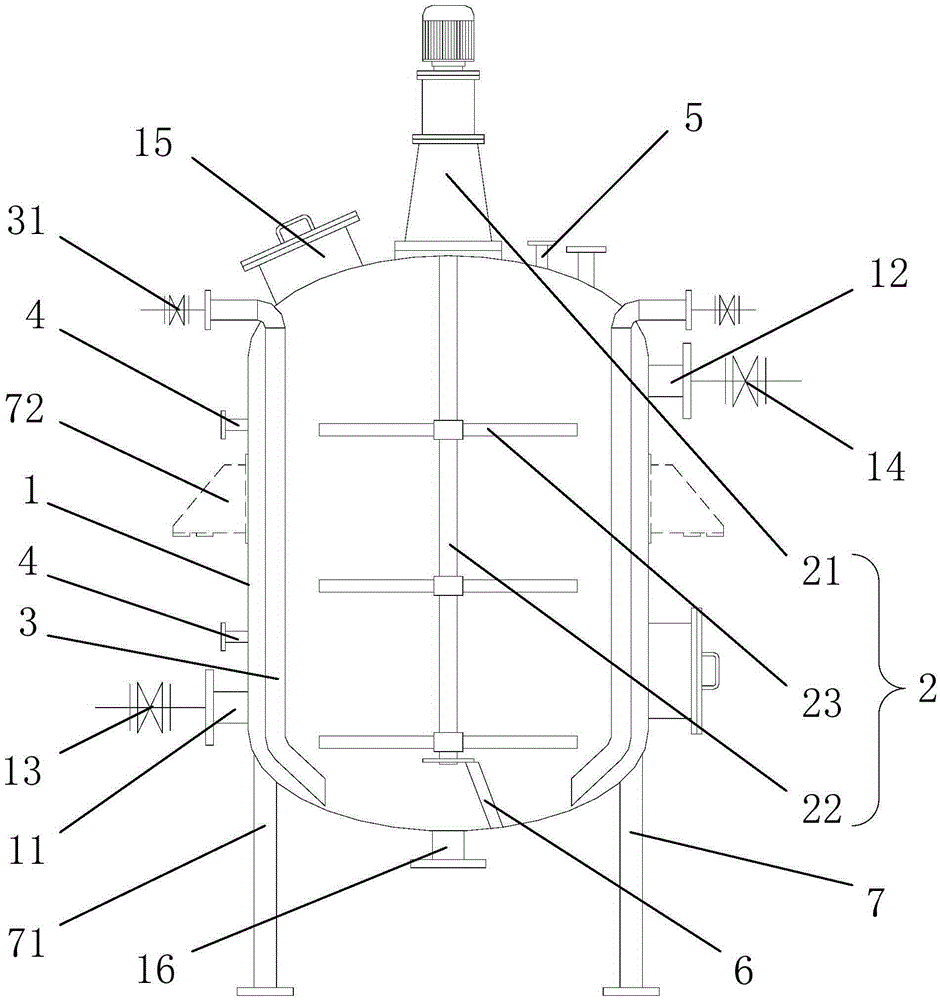

[0026] Such as figure 1 As shown, the continuous sludge thermal hydrolysis device provided in this embodiment includes a tank body 1, a stirring device 2, a steam pipeline 3, a temperature detection device 4 and a pressure detection device 5; wherein, the lower part of the side wall of the tank body 1 A feed port 11 is provided, a discharge port 12 is provided on the upper part of the side wall of the tank body 1, and a feed valve 13 and a discharge valve 14 are respectively provided at the feed port 11 and the discharge port 12; the stirring device 2 is arranged on In the tank body 1, it is used to mix the sludge and steam in the tank body 1 evenly; the steam pipe 3 penetrates into the tank body 1 from the top of the tank body 1, and extends down the inner wall of the tank body 1 to the bottom of the tank body 1 At the bottom, the entrance of the steam pipeline 3 is provided with a steam valve 31; the temperature detection device 4 is respectively arranged on the upper and lo...

Embodiment 2

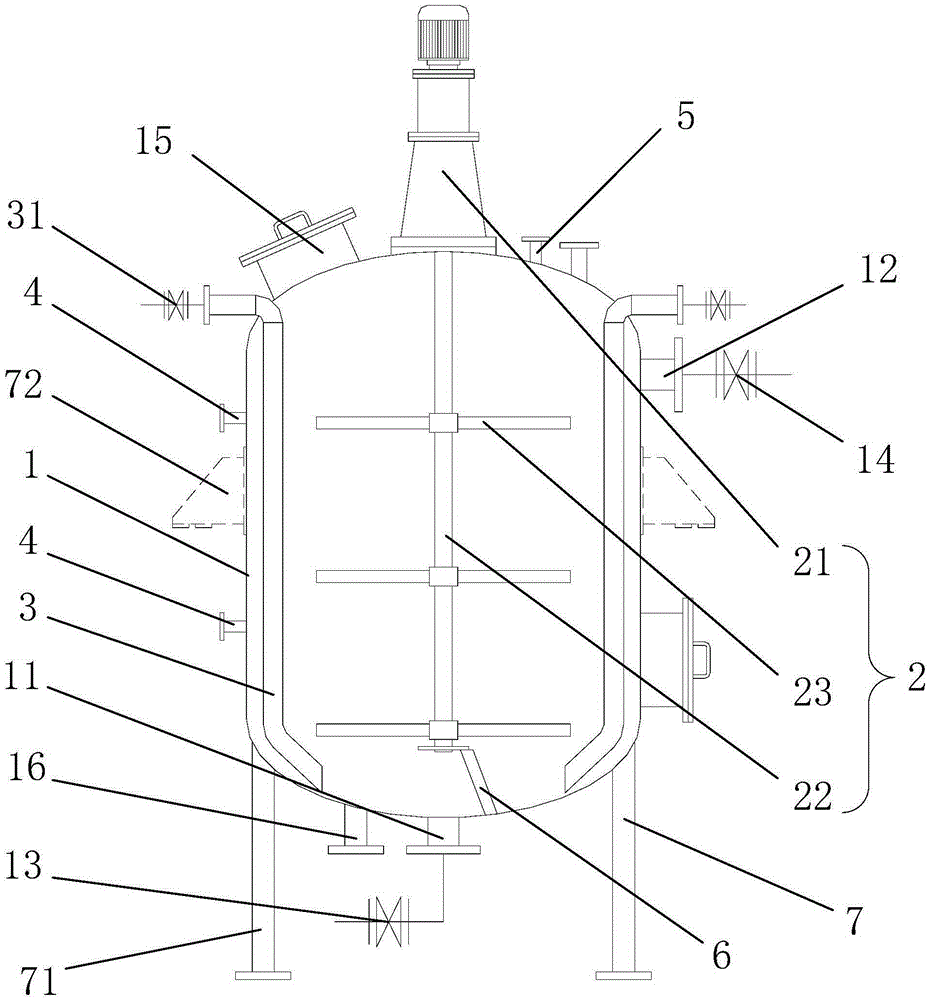

[0035] Such as figure 2 As shown, the structure of the continuous sludge thermal hydrolysis device provided in this embodiment is basically the same as that in Embodiment 1, the only difference being that the feed port 11 is arranged at the bottom of the tank body 1 in this embodiment.

Embodiment 3

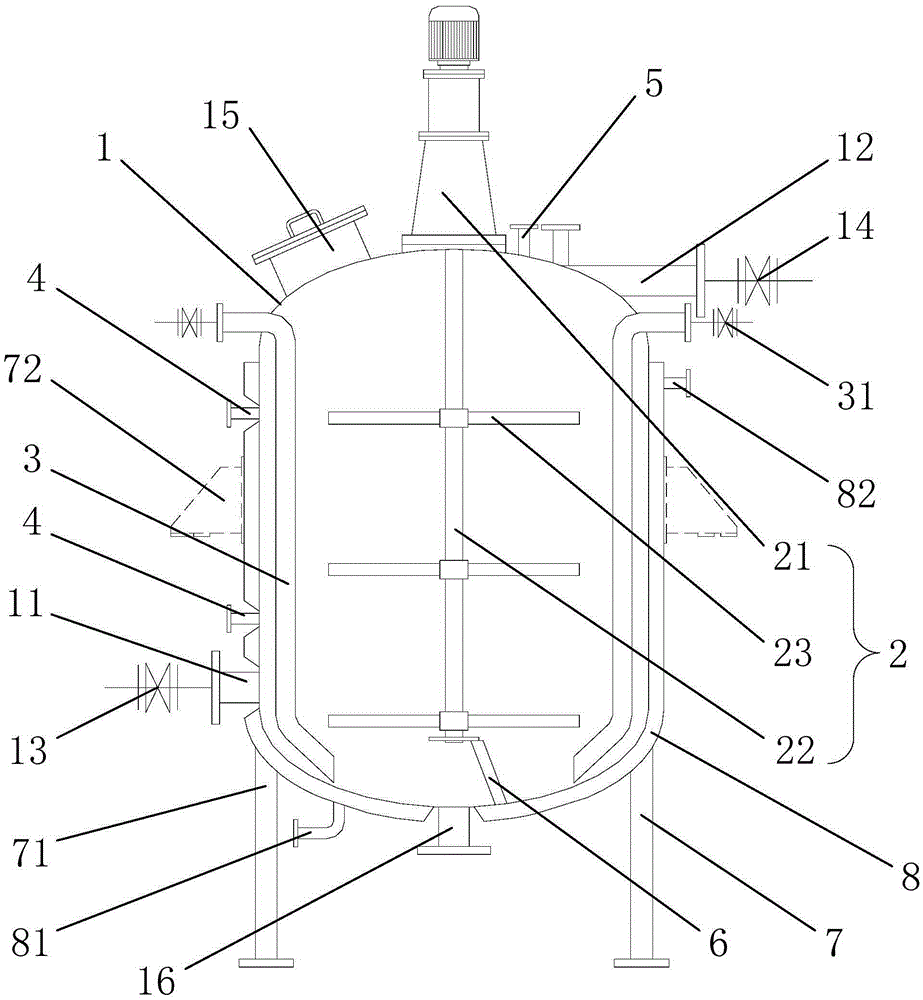

[0037] Such as image 3 As shown, the structure of the continuous sludge thermal hydrolysis device provided in this embodiment is basically the same as that of Embodiment 1, the only difference is that in this embodiment, a jacket 8 is provided outside the tank body 1, and the jacket 8 includes a steam inlet. 81 and steam outlet 82; when the temperature inside the tank body 1 does not reach the set temperature, high-temperature steam can be introduced into the jacket 8 to make the temperature inside the tank body 1 more stable and controllable. The whole process of hydrolysis provides a strong guarantee.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com