Production material circulation technology of oil casing coupling

An oil casing and material technology, which is applied in the field of material flow in the production of oil casing couplings, can solve the problems of complex process flow, high labor intensity, and low degree of automation, and achieves low labor intensity, high degree of automation, and low labor intensity. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

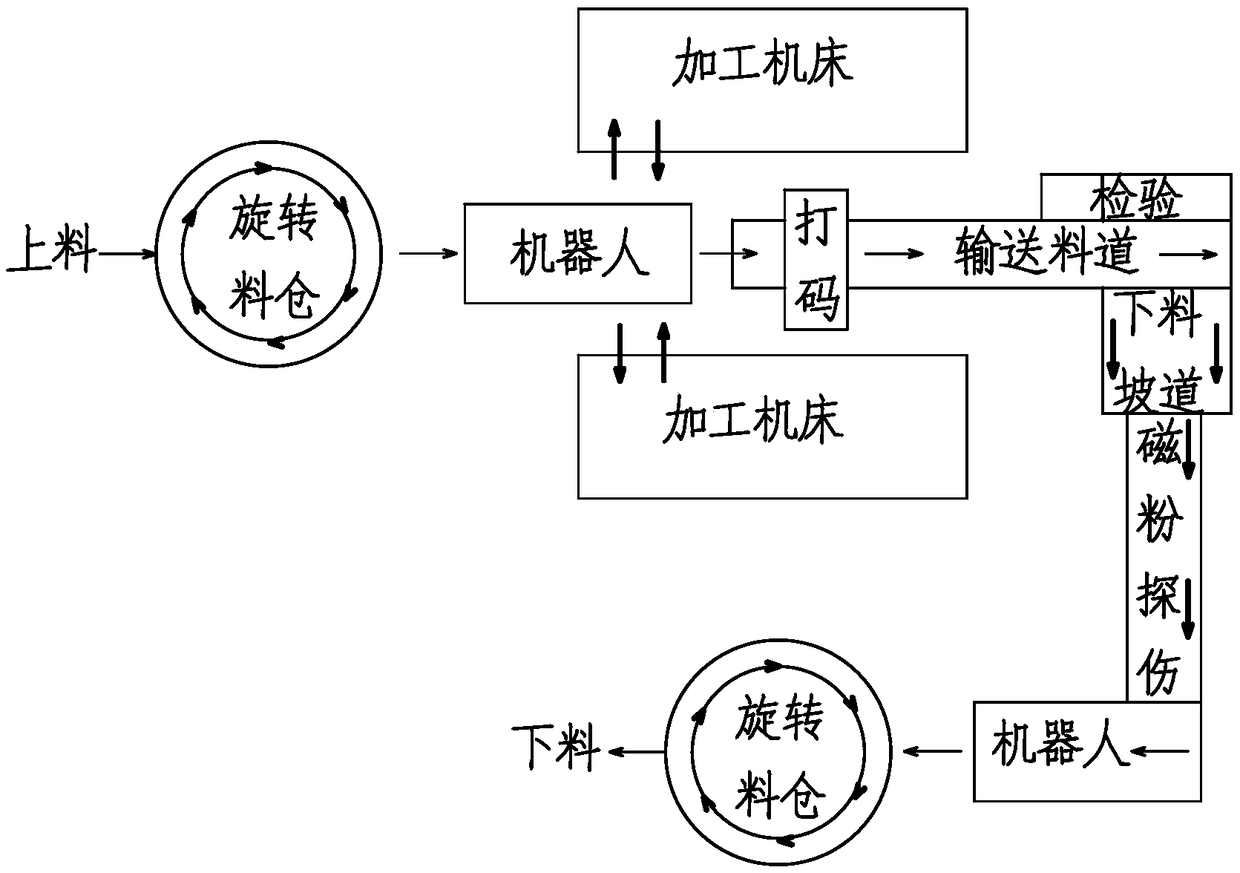

[0061] Please also refer to Figure 1 to Figure 4 , as a specific implementation of the material circulation process for the production of oil casing couplings provided by the present invention, the process of using a loading robot to load the blanks to the rotary silo at the loading level is as follows: The turnover basket with blanks is placed in the rotating silo, and the empty basket is unloaded by the loading forklift at the same time, and the other turnover basket with blanks is placed in the original empty basket position, and the two turnover baskets with blanks are kept on the top at the same time Material level on the rotating silo. The rotating silo can ensure that two baskets are online at the same time. When one basket is unloaded or loaded, the vacancy can be filled in time through the rotating silo to ensure continuous production.

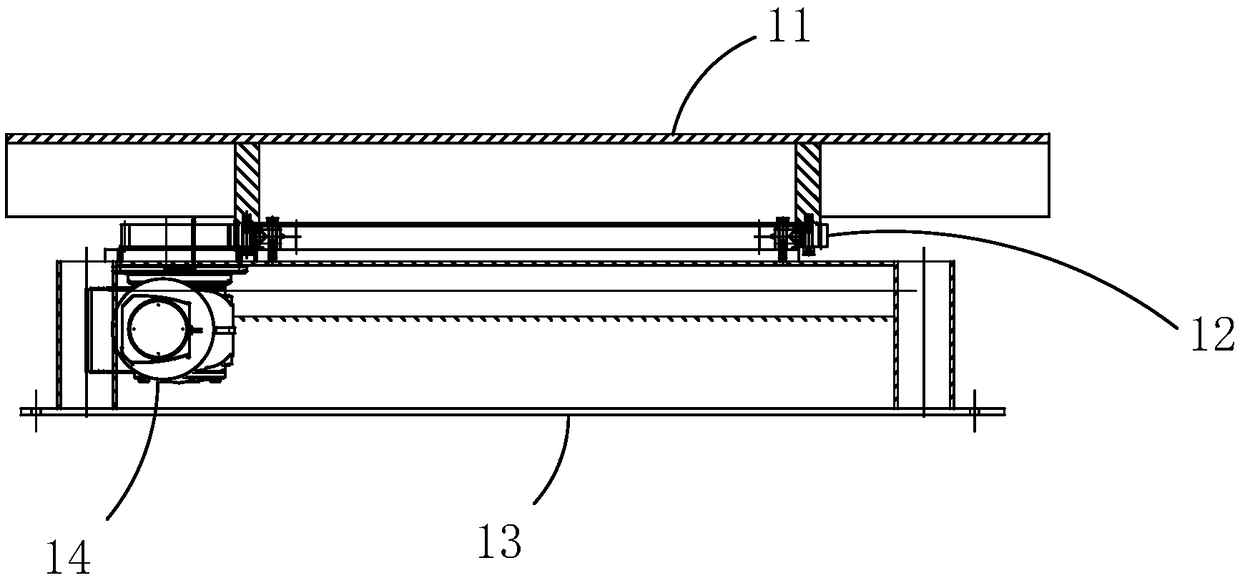

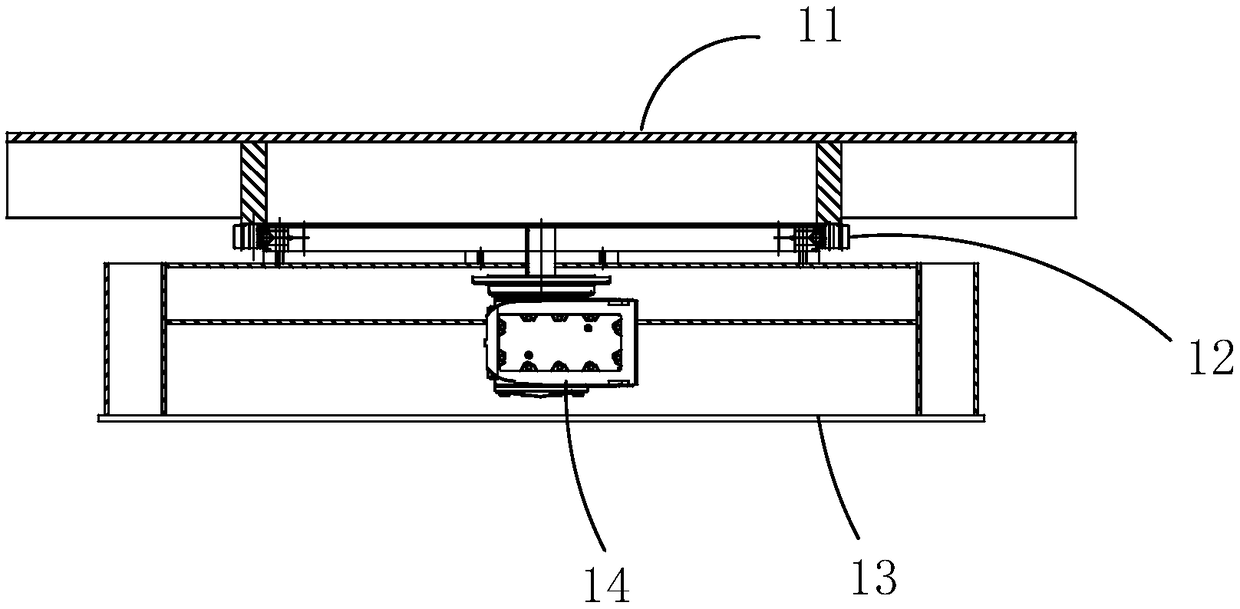

[0062] see Figure 1 to Figure 7 , as a specific embodiment of the material circulation process for the production of oil and cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com