Full-automatic screen printer

A screen printing machine, fully automatic technology, applied in screen printing machine, printing machine, rotary printing machine, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

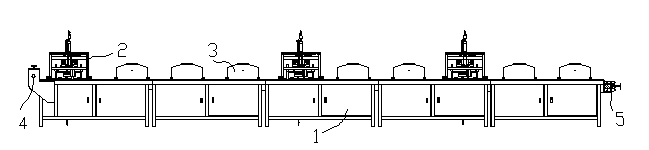

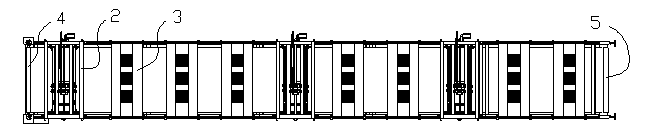

[0015] figure 1 , figure 2 with image 3 The structure of the preferred embodiment of the present invention is schematically shown. As shown in the figure, the preferred embodiment of the present invention includes a control system (not shown, which may be a data processing device such as a PLC), a workbench 1 and a workbench 1 Multiple printing systems 2, multiple ovens 3 for multi-color printing. The table top of the worktable 1 is preferably actinic glass. The control system is connected with a plurality of printing systems 2 to control its operation sequence. At least two ovens 3 are provided between two adjacent printing systems 2 to improve the baking efficiency. Between the lower part of the oven 3 and the workbench 1 There is a certain distance to facilitate the passage of the substrate.

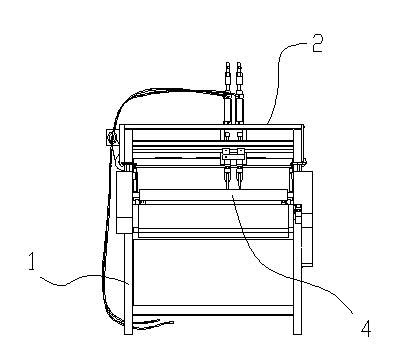

[0016] Such as Figure 4 with Figure 5 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com