Patents

Literature

41results about How to "Achieve continuous printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

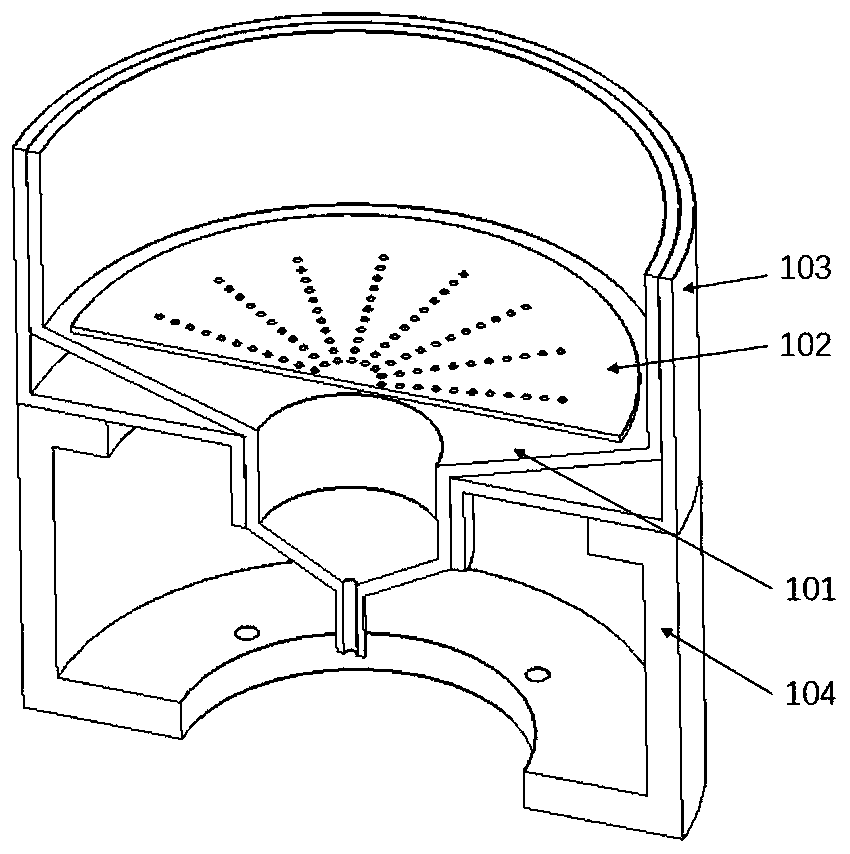

High-speed continuous photocuring type 3D printing device and working method thereof

ActiveCN106426915ALow costEfficient continuous printingManufacturing irradiation arrangementsManufacturing material handlingLiquid surfacesOxygen rich

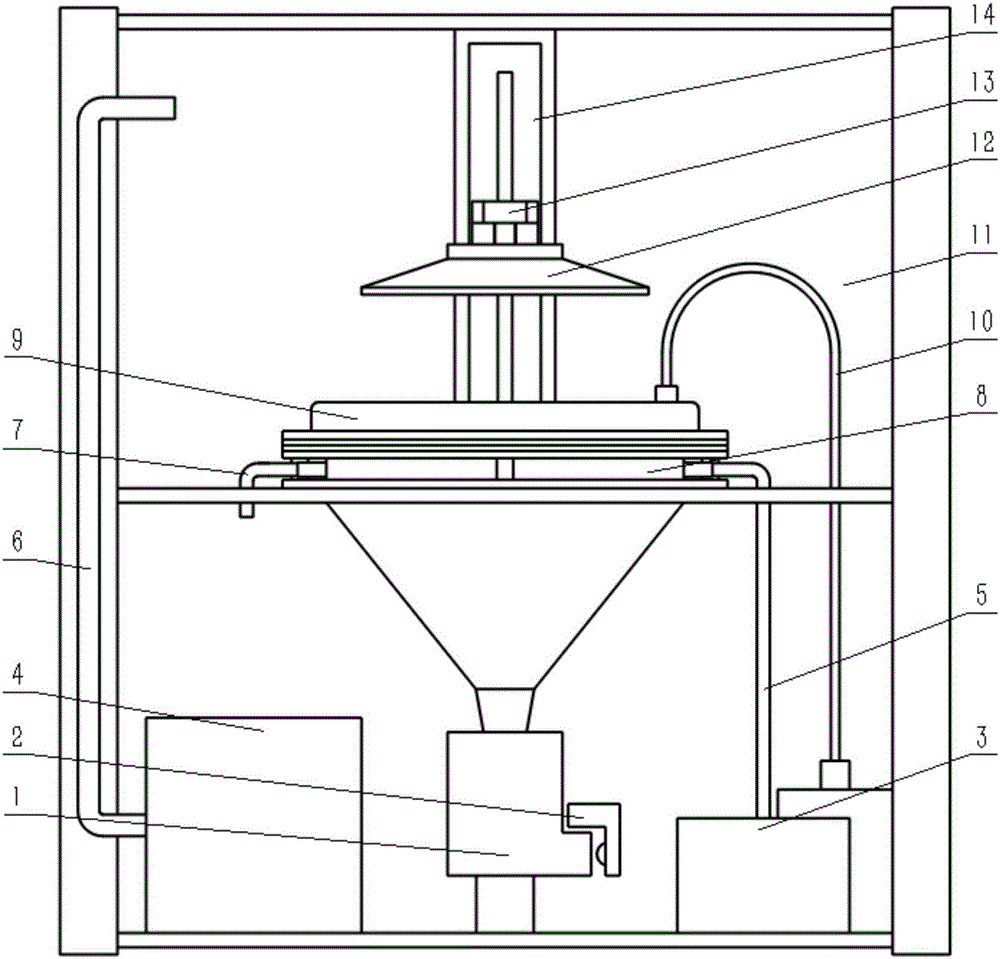

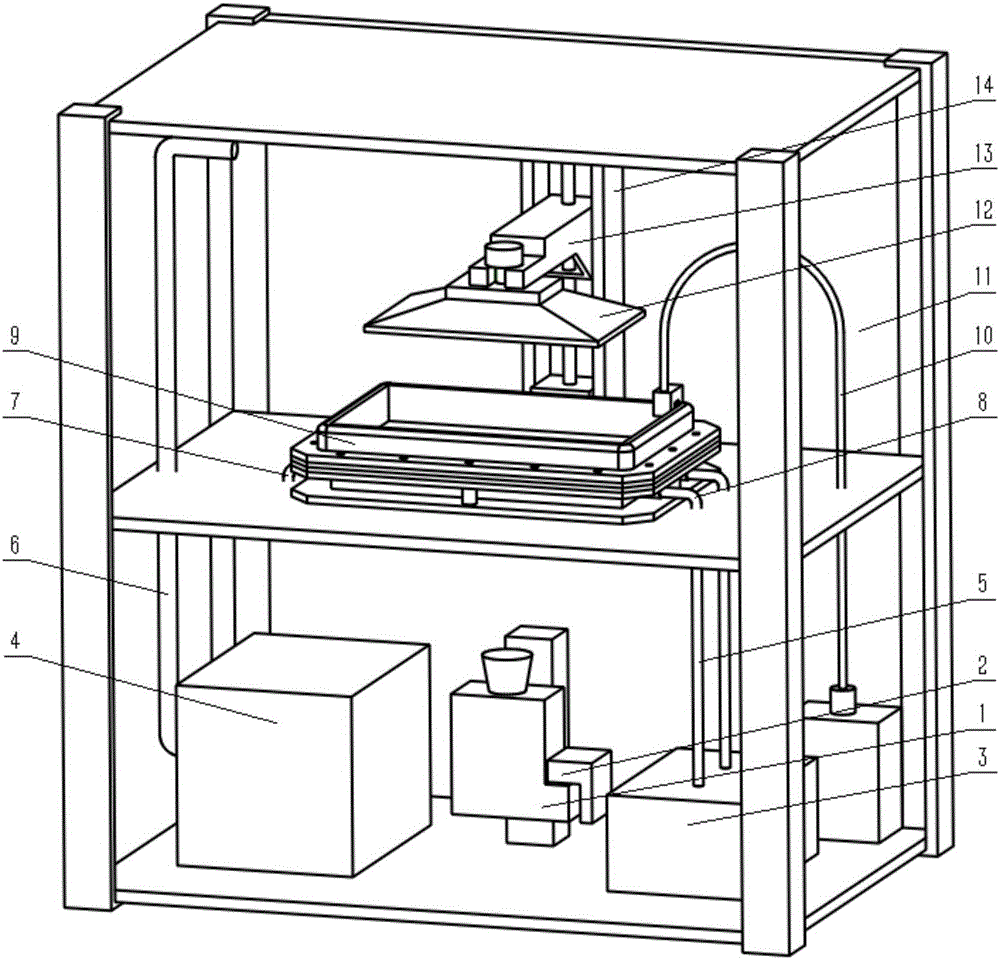

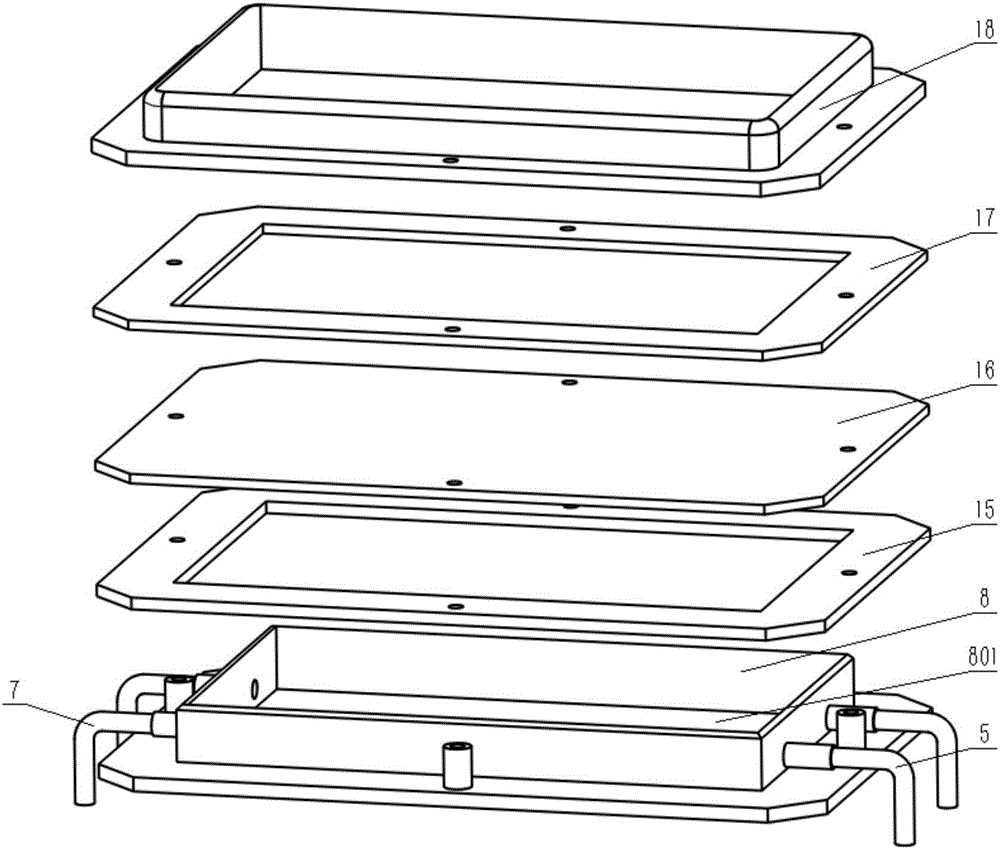

The invention discloses a high-speed continuous photocuring type 3D printing device and a working method thereof. The 3D printing device comprises a machine case body which is divided into an upper cavity and a lower cavity by a middle partition board, wherein an image forming module is arranged in the lower cavity, a window box and an oxygen supply cooling module are arranged in the upper cavity and are combined to be fixedly mounted on the middle partition board, the oxygen supply cooling module is arranged right below the window box, and the image forming module I is arranged right below the window box; a printing platform is arranged right above the window box and is mounted on a Z-direction worktable; and the window box is connected with a raw material feeding unit. The 3D printing device is integrated with the advantages of a compound oxygen-rich film, oxygen supply cooling and liquid surface auxiliary pressurization of the window box, so that the low-cost and efficient continuous printing of large-sized products with arbitrary shapes is realized, the range of applicable materials is wide, the printed products are high in precision and quality and good in uniformity, and the process is stable and reliable. An industrial-grade solution is provided for the high-speed continuous photocuring type 3D printing.

Owner:SHENZHEN ELEGOO TECH CO LTD

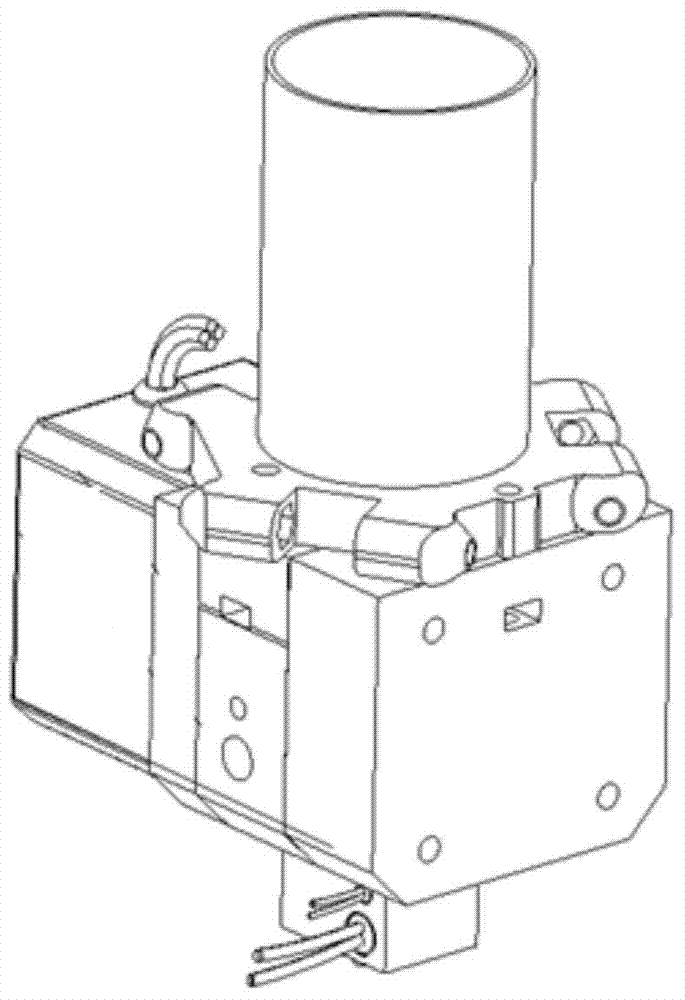

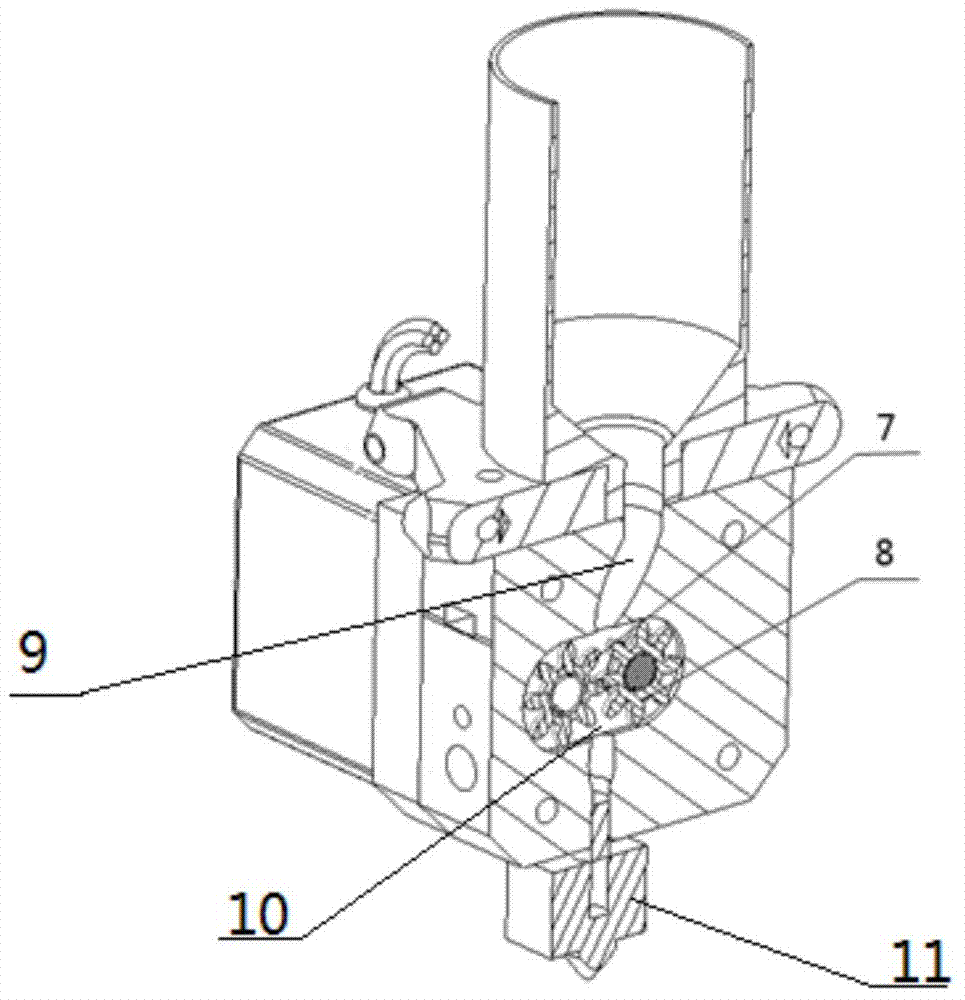

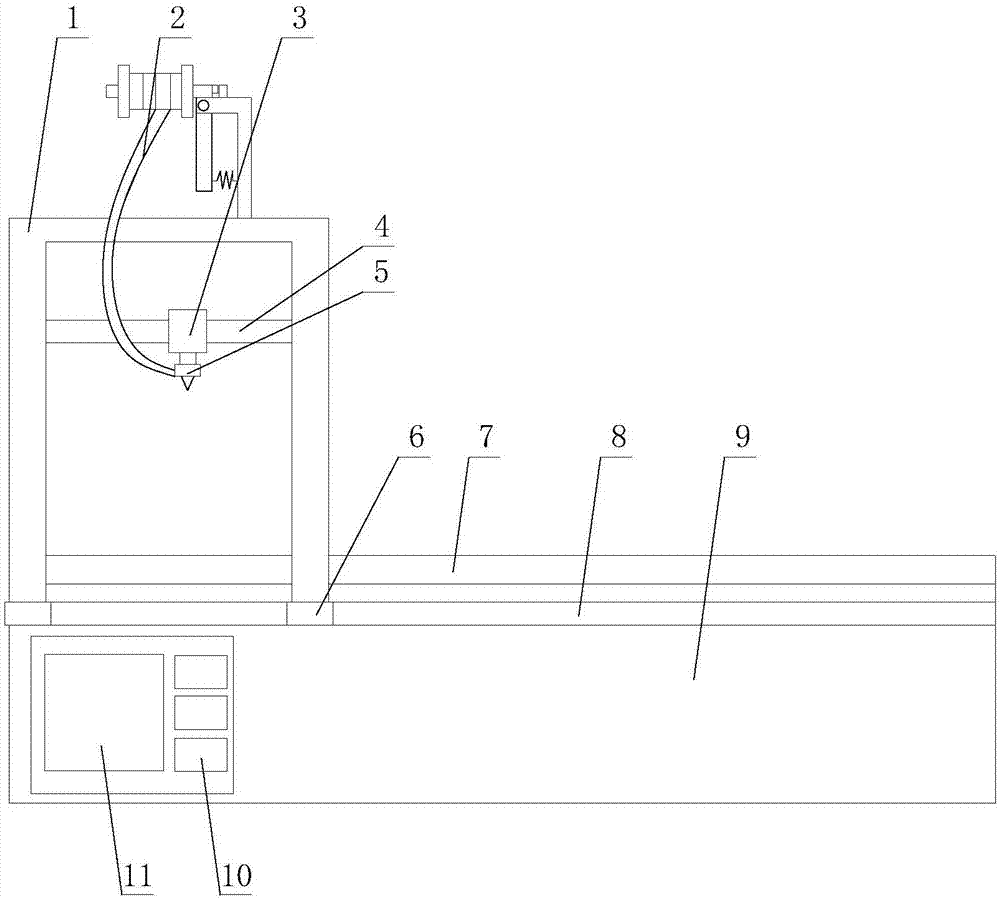

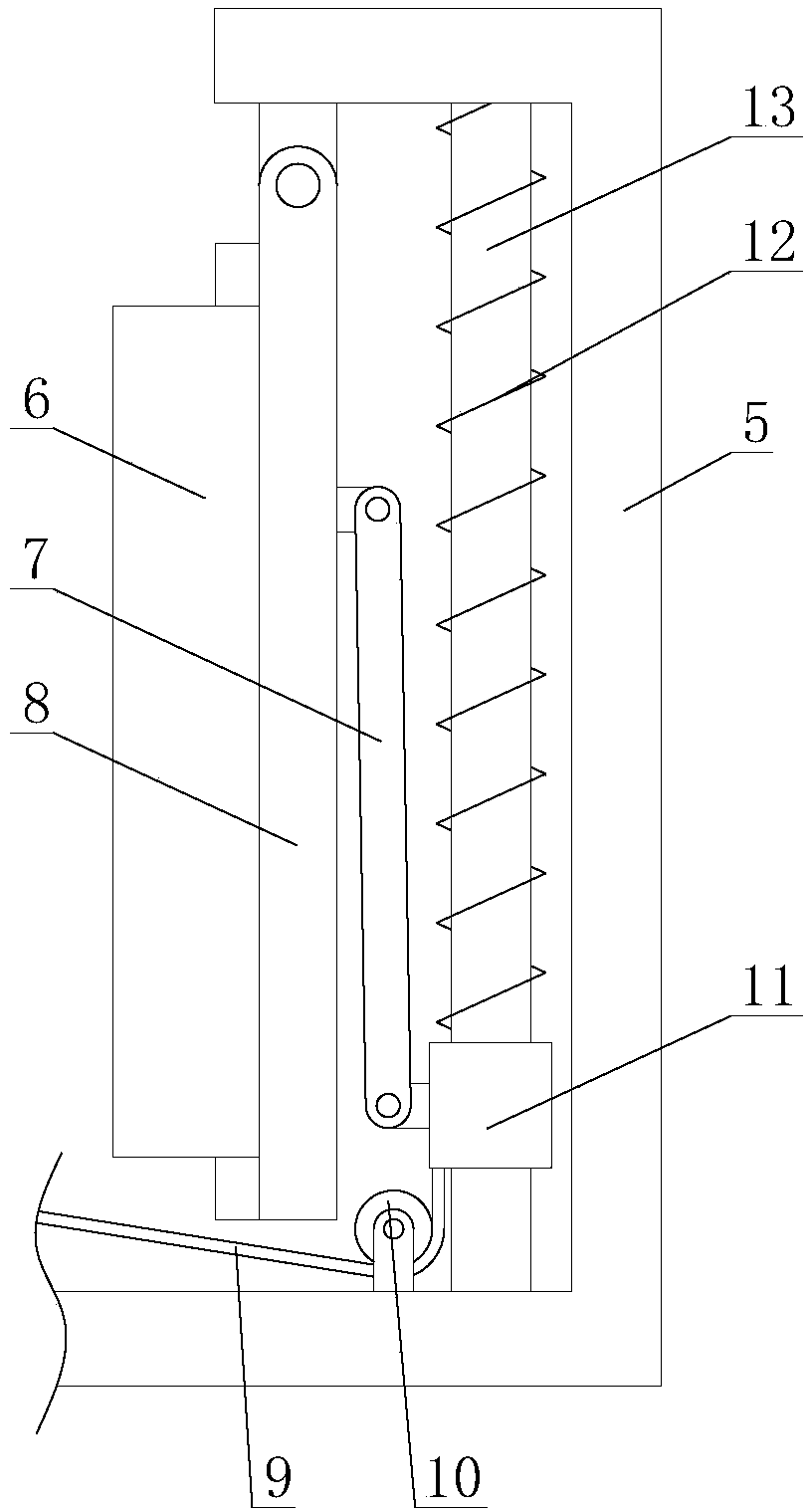

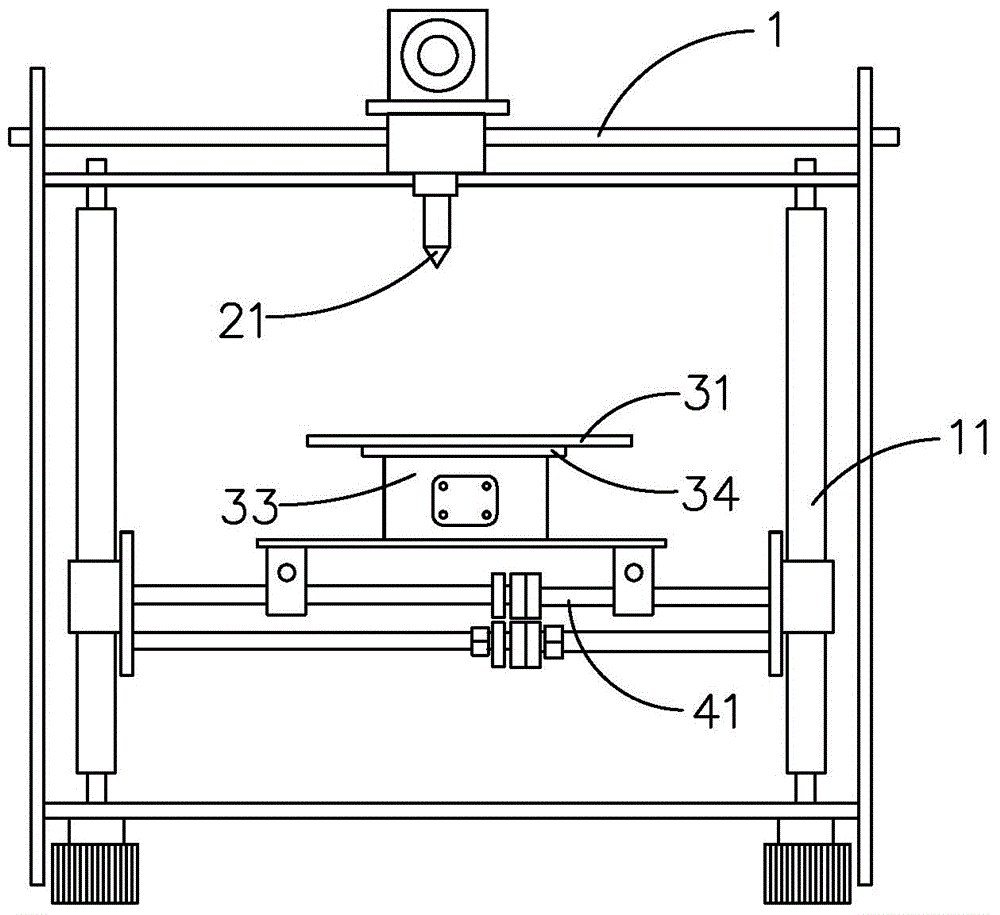

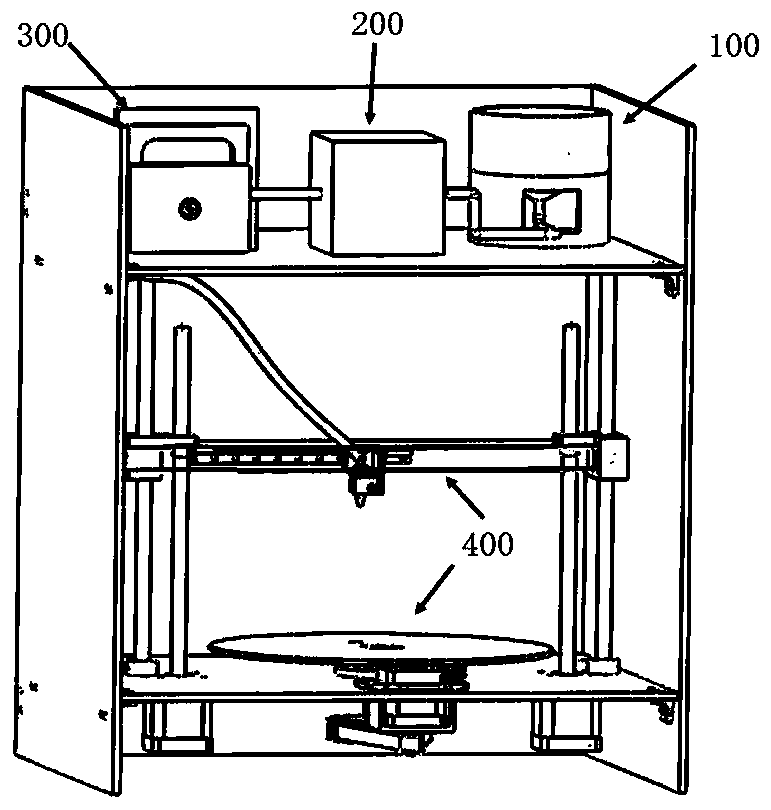

Three-dimensional printer

ActiveCN104723558AAchieve continuous printingGuaranteed accuracyAdditive manufacturing apparatusSpray nozzleEngineering

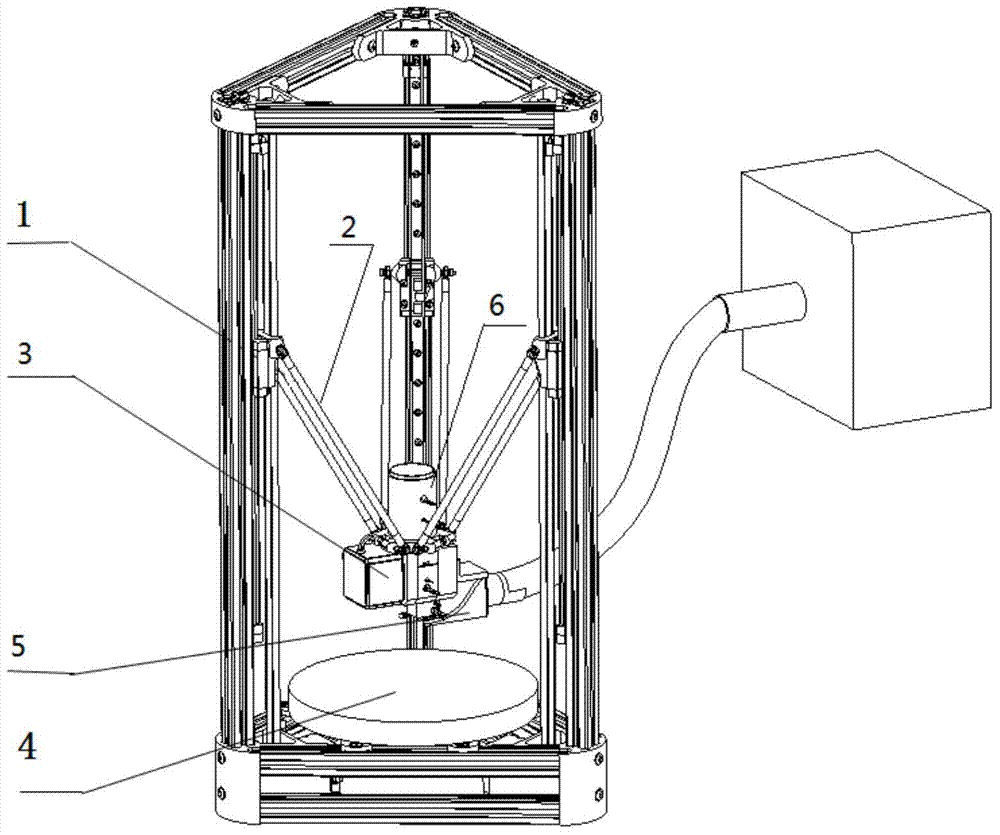

The invention provides a three-dimensional printer. The three-dimensional printer comprises a stander, a printing head moving mechanism, a supply unit and a printing head; the printing head comprises a feeding channel, a chamber, a rotor mechanism and a spray nozzle; one end of the feeding channel is connected with a supply unit, the other end of the feeding channel is connected with the chamber, a three-dimensional printing material in the supply unit is guided to the chamber of the printing head; one end of the chamber is connected with the feeding channel, and the other end of the chamber is connected with the spray nozzle; the rotor mechanism is arranged in the chamber, the rotor mechanism comprises a driving gear and a driven gear, and the peripheral part of the driving gear and the peripheral part of the driven gear are fit to the inner wall of the chamber. By adopting the printing head with a rotor, the printing material can be injected into the chamber of the printing head to realize the continuous printing; moreover, the tooth pitch of the rotor in the printing head is fixed, so that the printing precision can be guaranteed.

Owner:HARBIN INST OF TECH AT WEIHAI

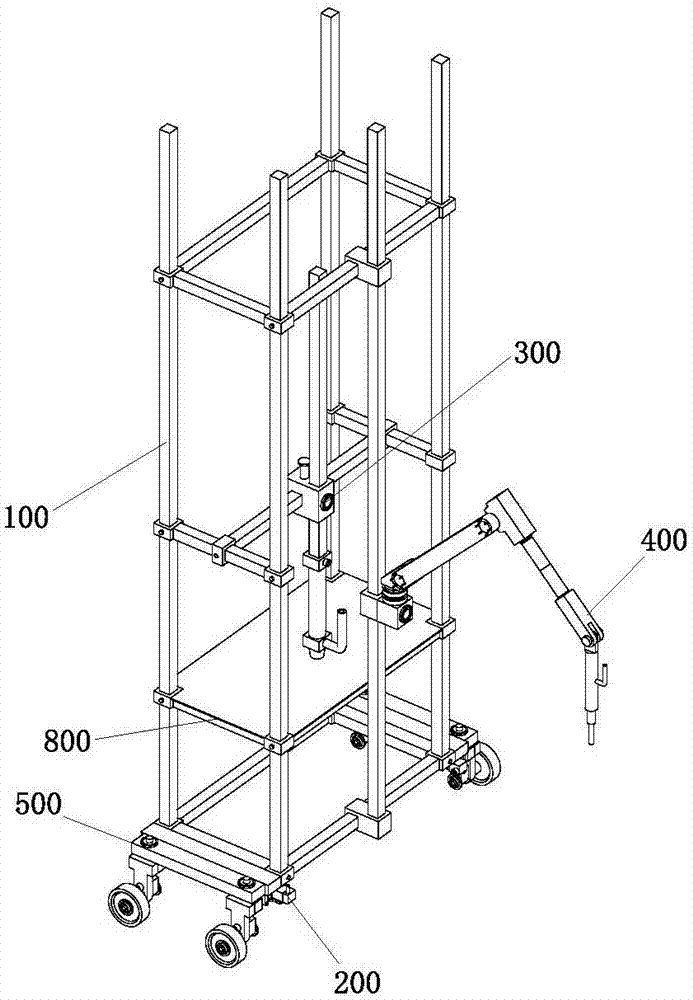

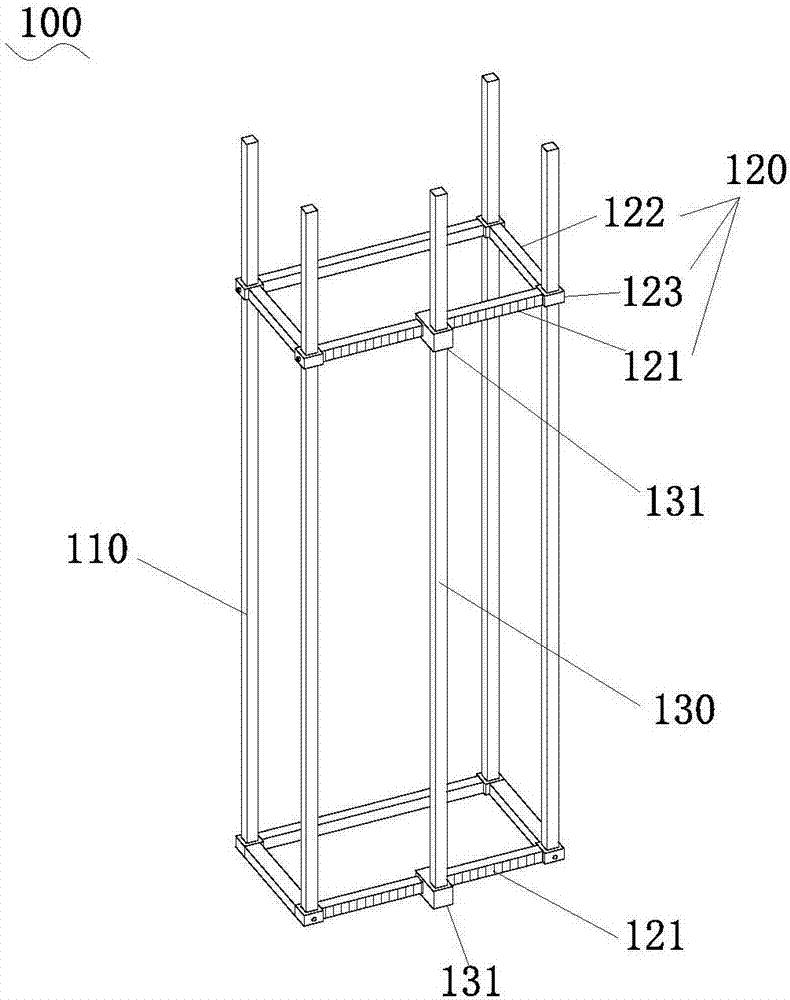

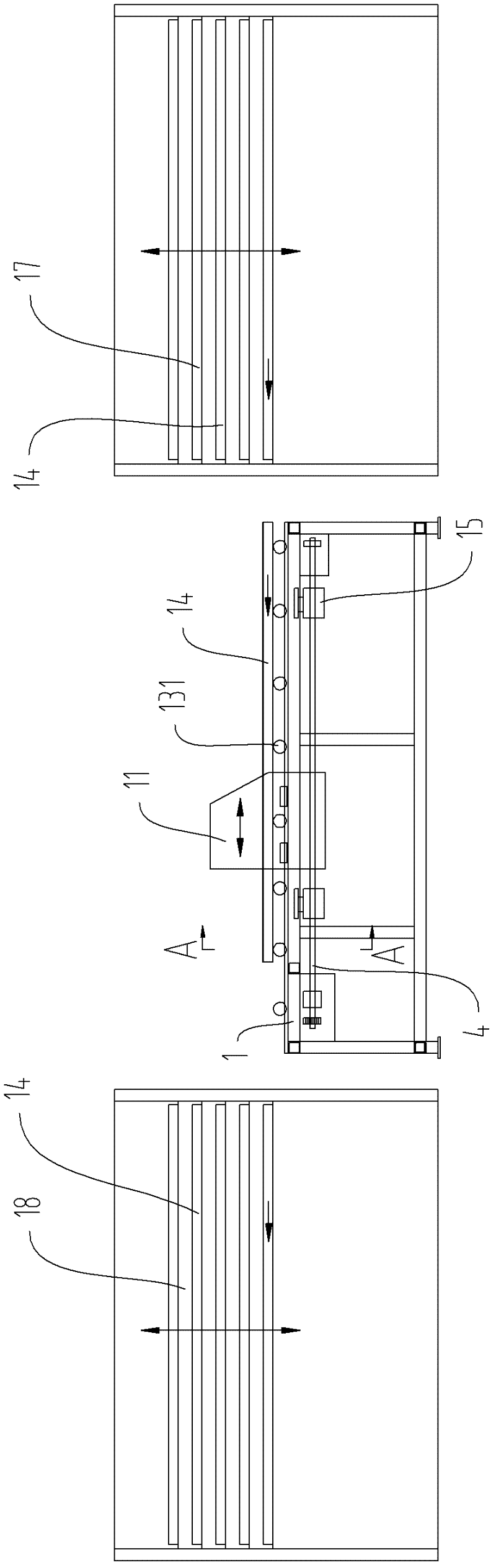

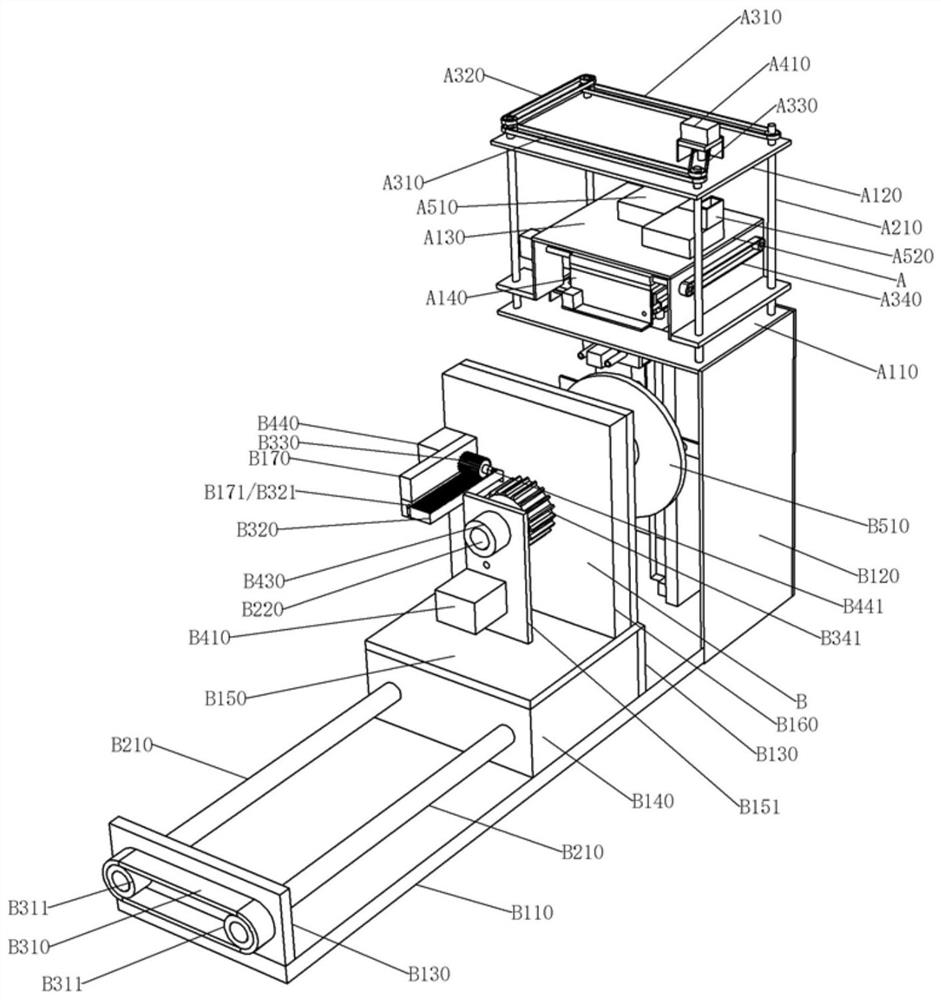

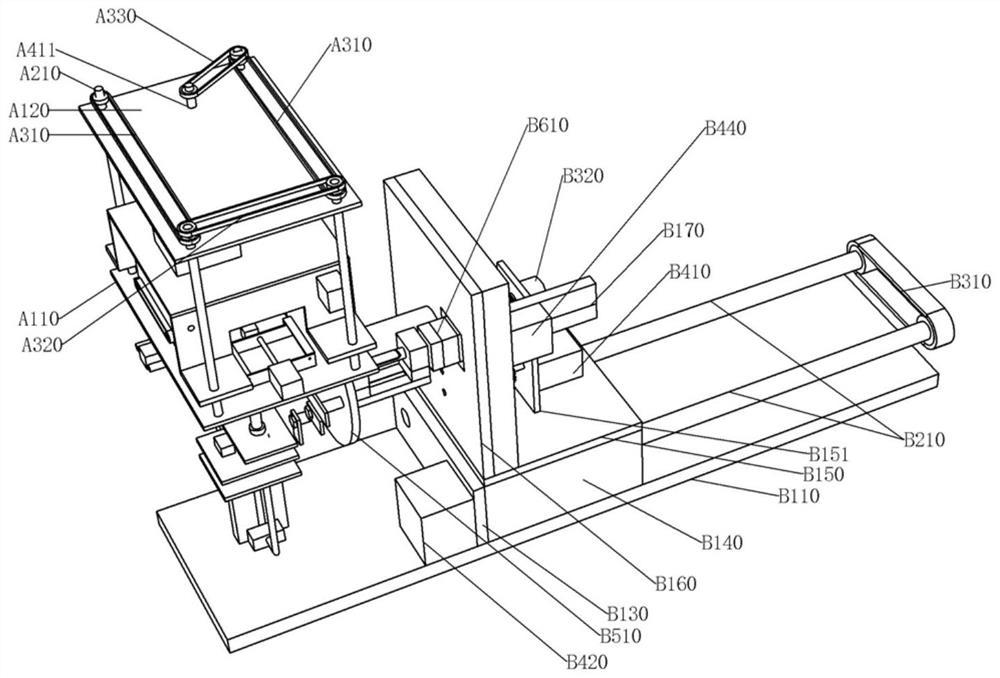

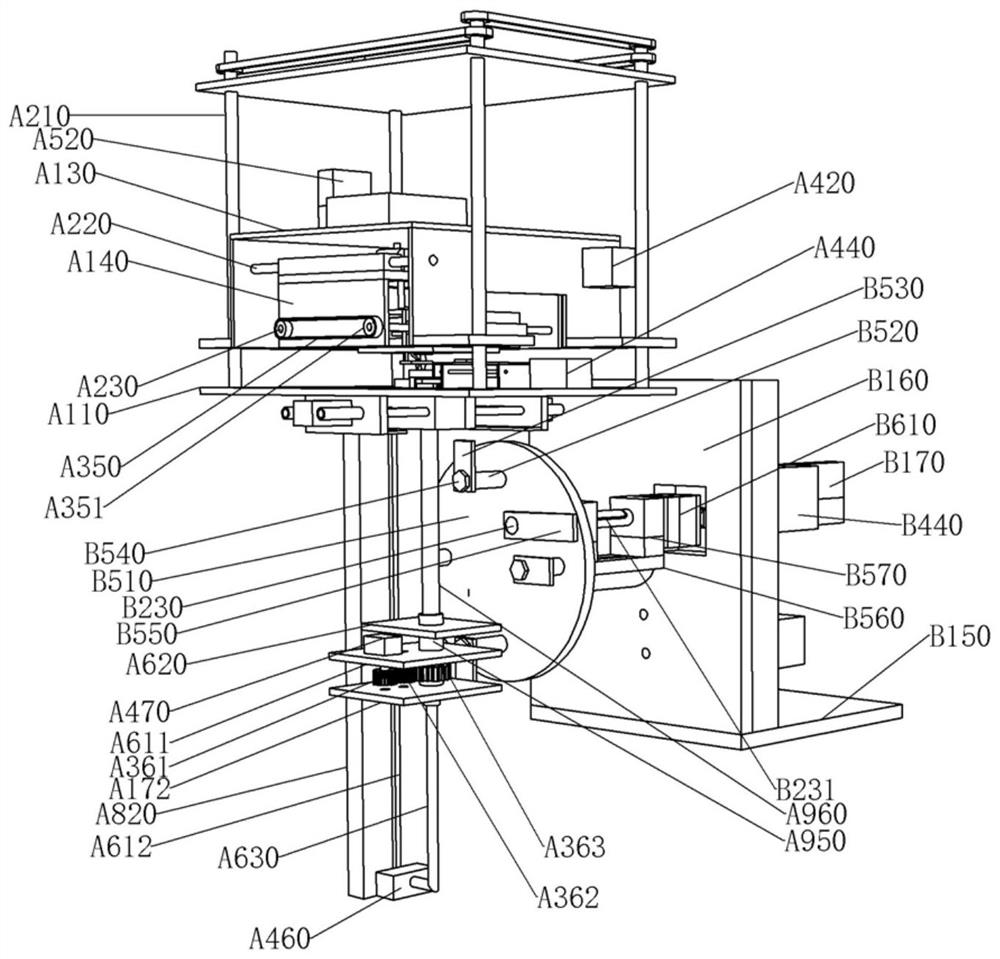

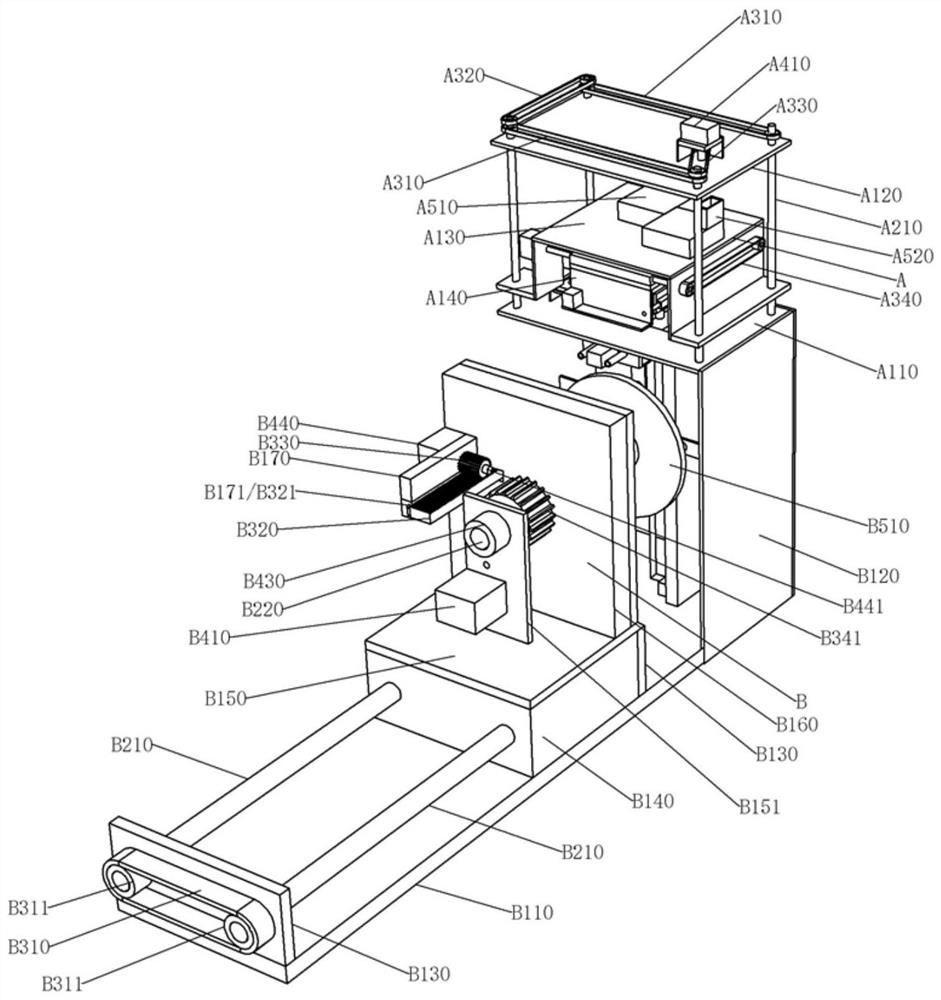

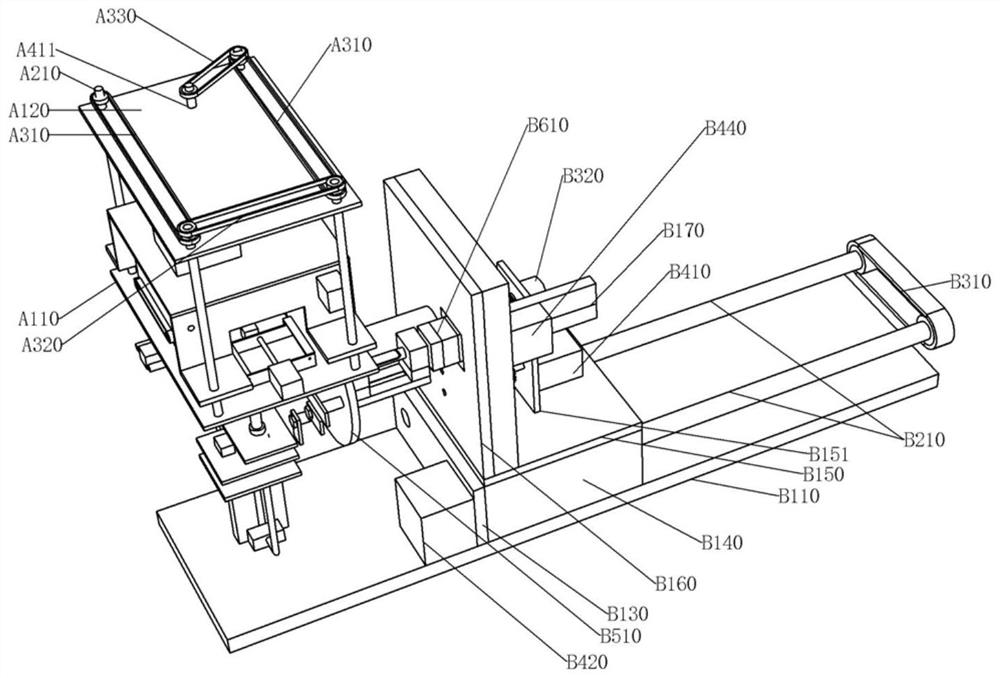

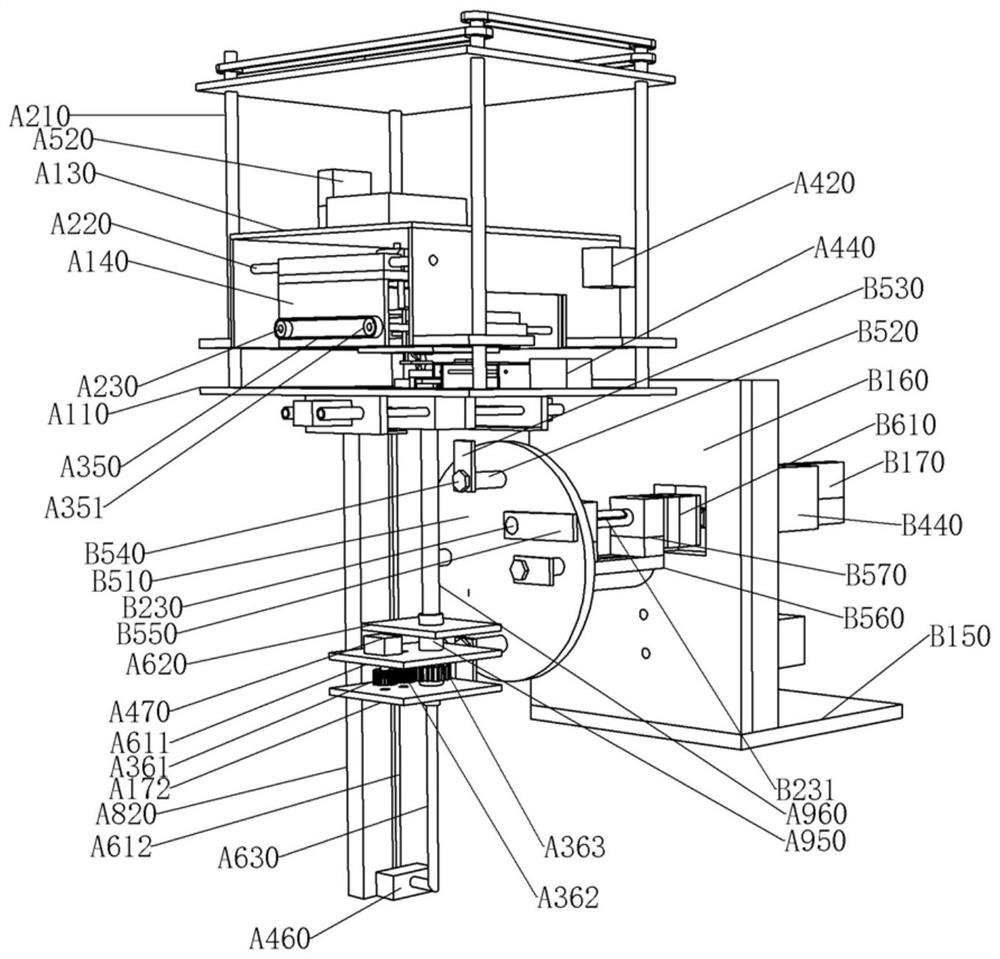

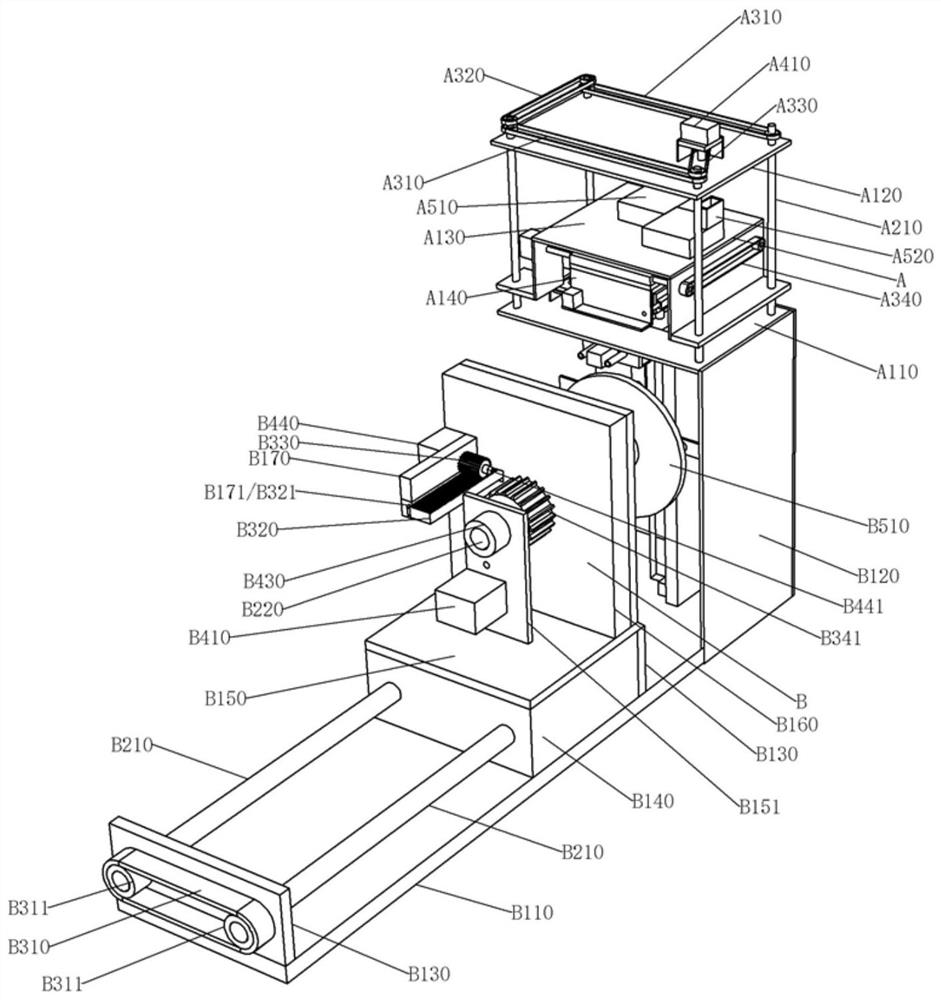

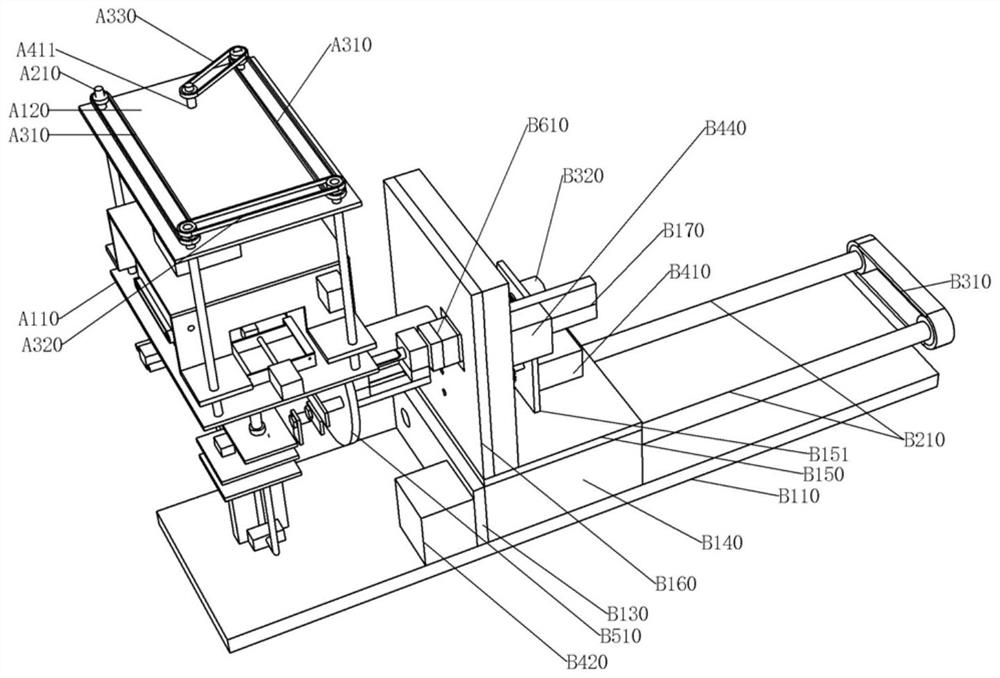

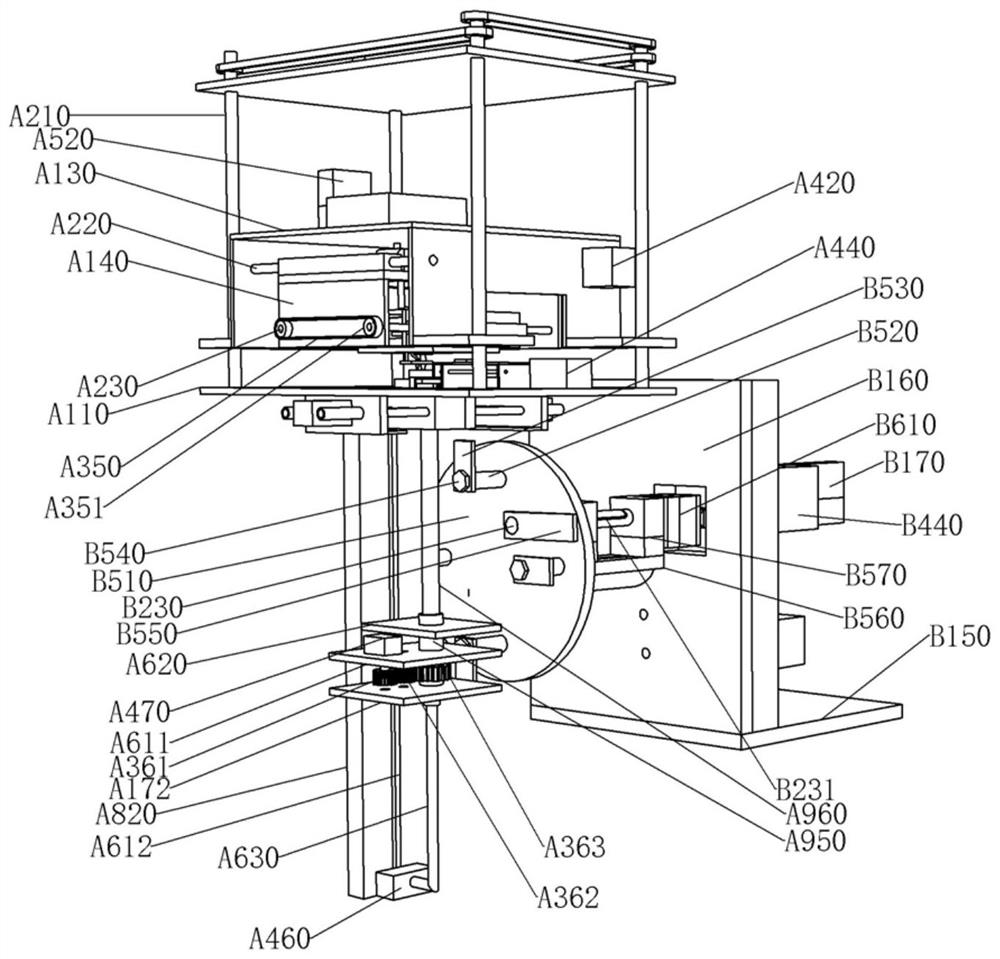

Bridge 3D printing with formwork collaboration and construction method thereof

ActiveCN107974950AFully automaticAchieve continuous printingBridge erection/assemblyEngineering3d printer

The invention relates to a bridge 3D printing with formwork collaboration and a construction method thereof and belongs to the technical field of building construction. The bridge 3D printing device comprises a guide frame, a guide rail travelling mechanism, a bridge 3D printing mechanism, a rail 3D printing mechanism and a collaborating formwork; the guide frame provides supporting for the bridge3D printing mechanism, the rail 3D printing mechanism and the collaborating formwork; the rail 3D printing mechanism provides 3D printing for a rail support structure; the guide rail travelling mechanism supports the guide frame the rail support structure that is constructed; the bridge 3D printing mechanism can print a bridge body; the collaborating formwork can provide supporting for the bridgebody during printing. The bridge 3D printing with formwork collaboration and the construction method thereof have the advantages that complex formwork erection and removal operations during traditional bridge printing are avoided so that construction efficiency is improved; the bridge 3D printing with formwork collaboration can provide full-automatic continuous printing.

Owner:SHANGHAI CONSTRUCTION GROUP +1

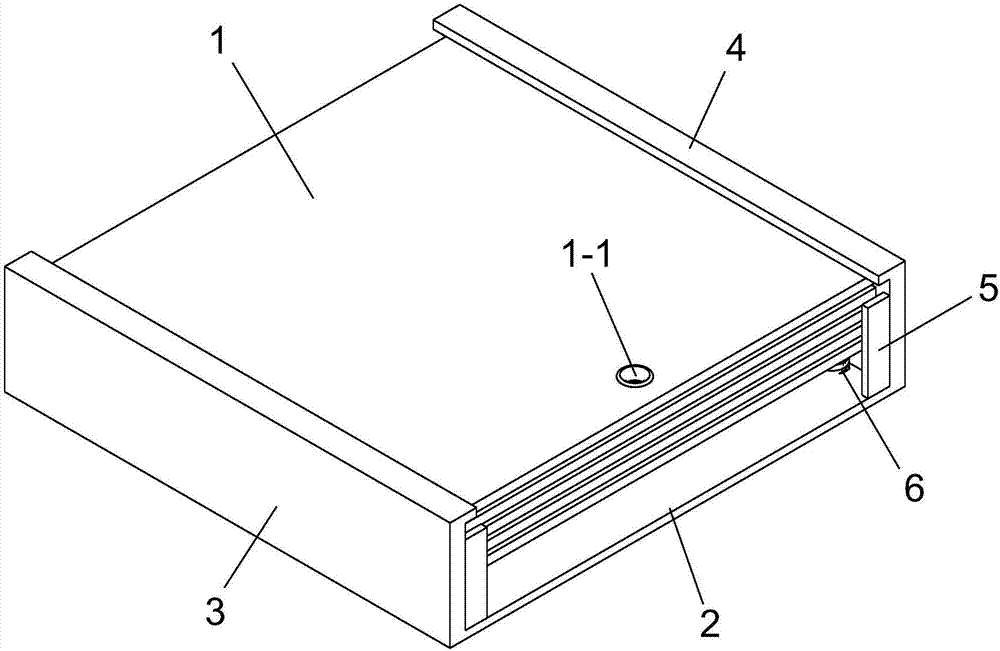

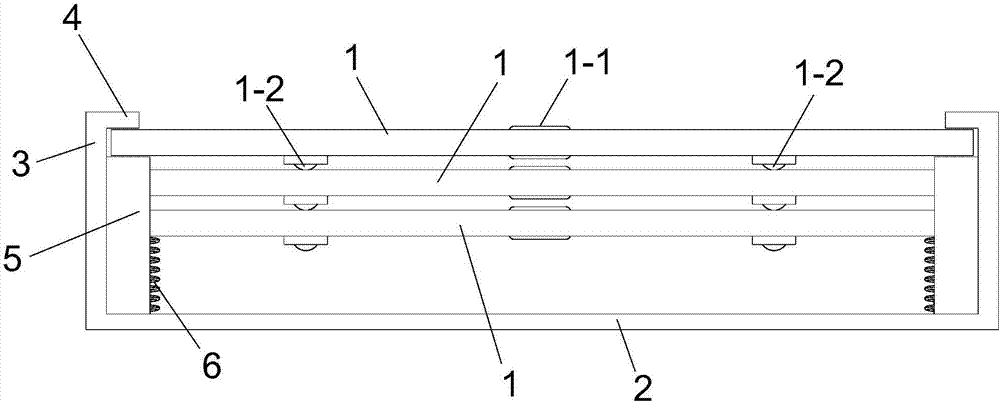

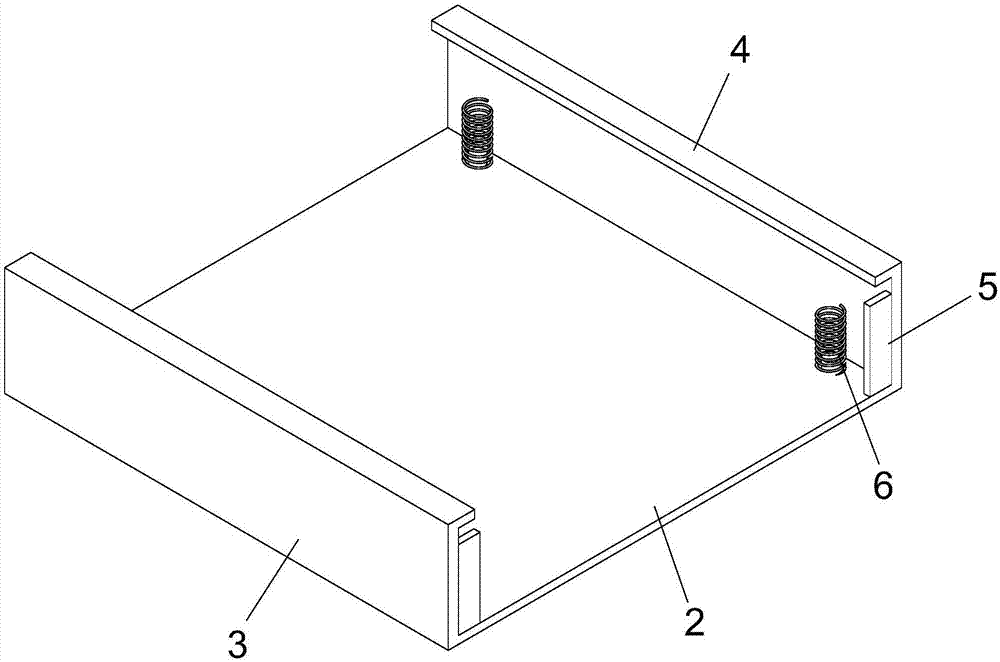

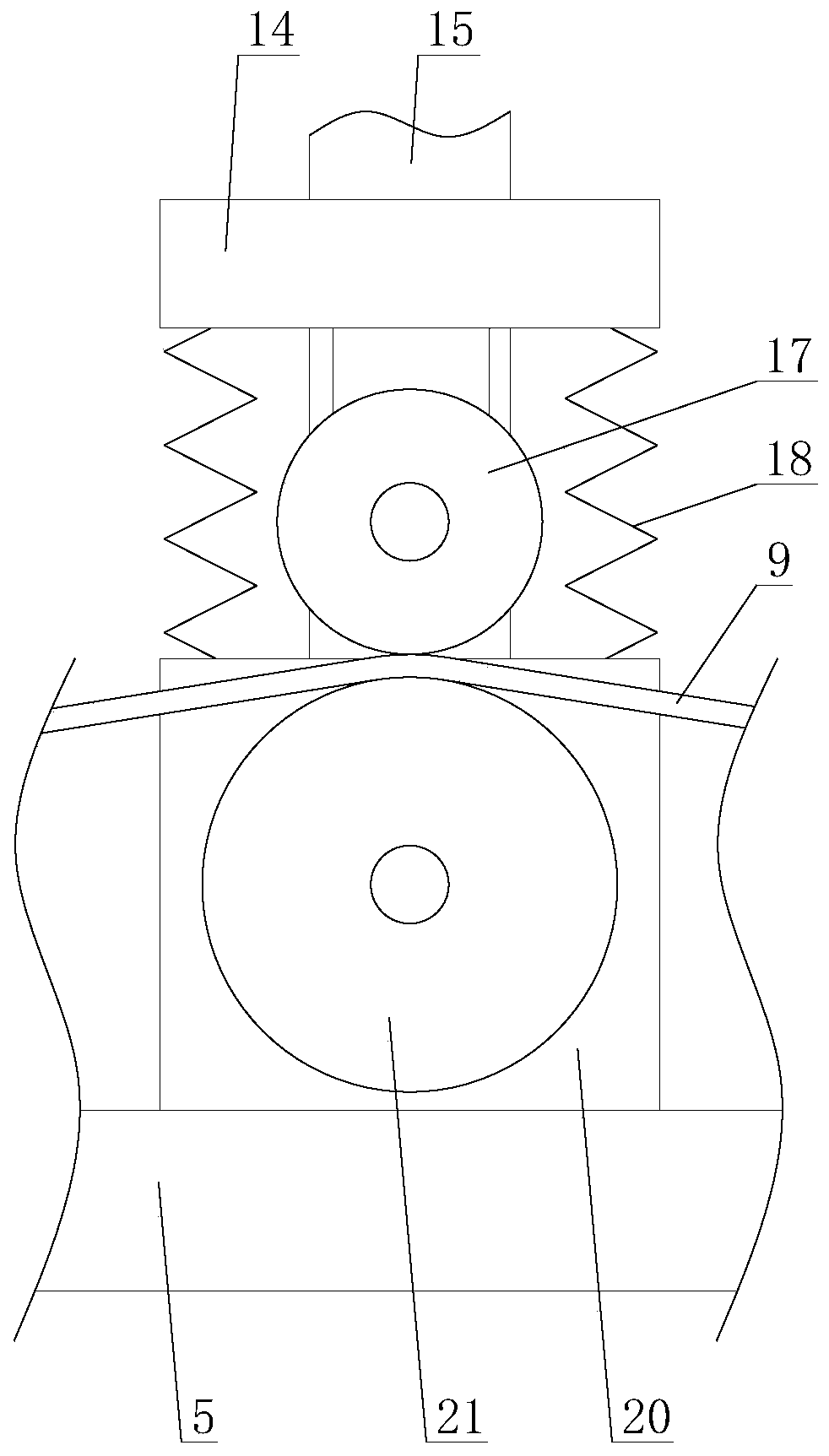

Intelligent 3D printer capable of achieving continuous printing function

ActiveCN107263871AAvoid damageExtended service lifeManufacturing driving means3D object support structuresFixed frameElectromagnet

Owner:南京神舟航天智能科技有限公司

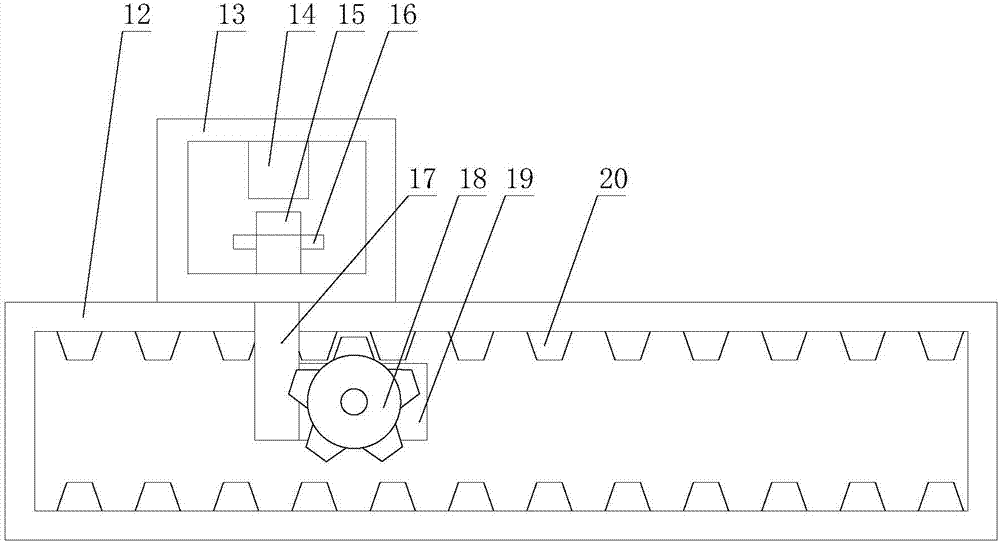

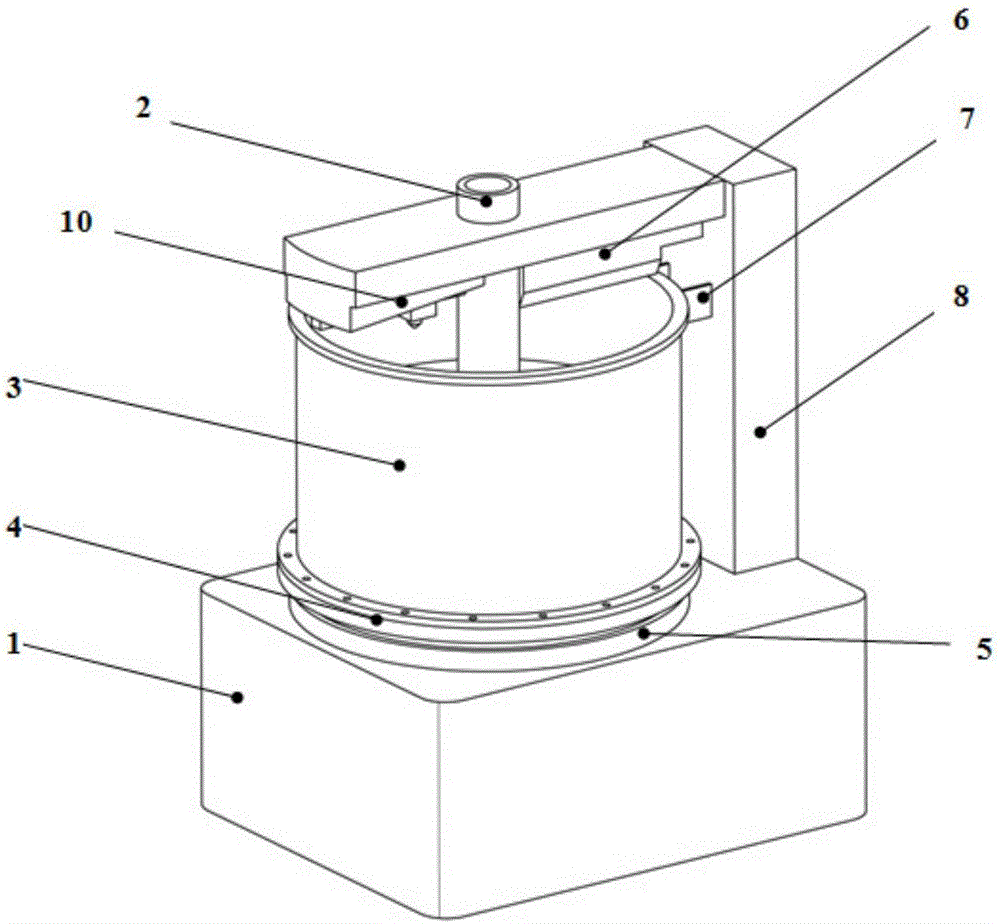

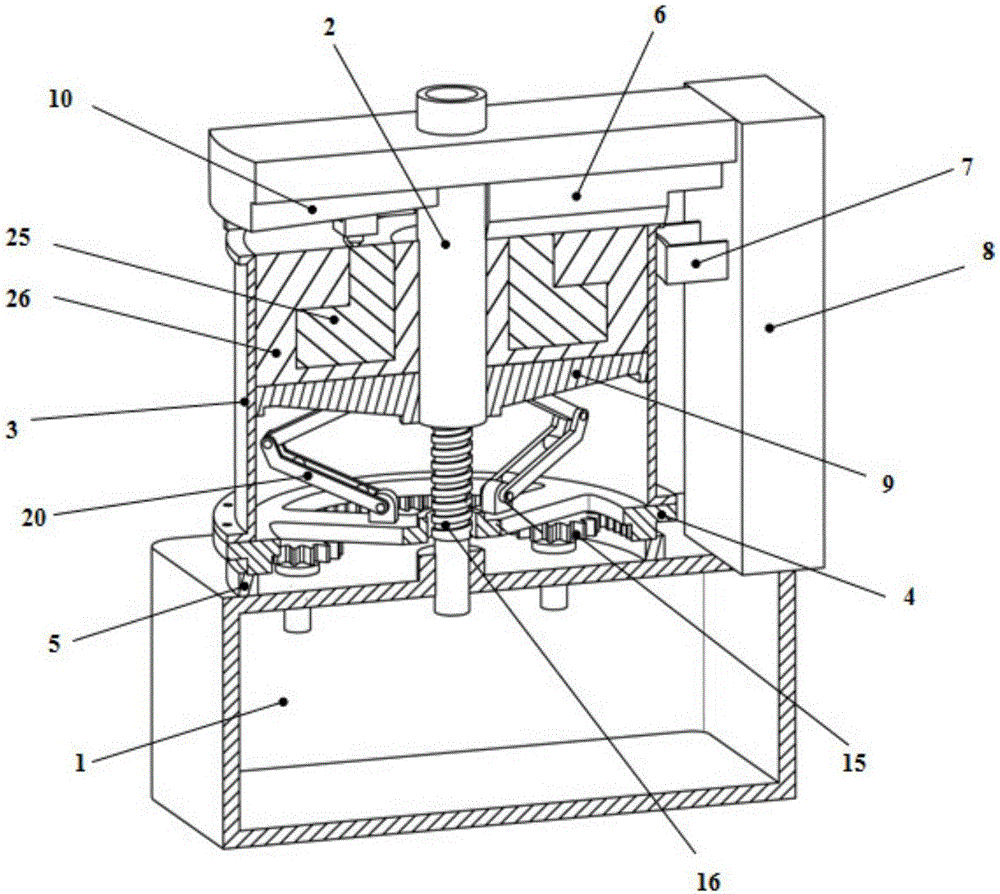

Rotary type sand mold three-dimensional printer

InactiveCN105710309AShorten the timeImprove efficiencyAdditive manufacturing apparatusFoundry mouldsEngineeringMachining time

The invention provides a rotary type sand mold three-dimensional printer and belongs to the technical field of sand mold three-dimensional printing. The rotary type sand mold three-dimensional printer comprises a base, a working cylinder, an axial contact bearing, a workbench, connecting rod mechanisms, a lead screw nut, a hollow rod, a lead screw, a sand laying bin, a printing head moving mechanism and a support. The working cylinder and the workbench are connected through a set of connecting rod mechanisms. The hollow rod provided with the lead screw nut is fixedly connected with the workbench and connected with the base through the lead screw. The sand laying bin and the printing head moving mechanism are located at the top of the working cylinder and fixedly connected with the base through the support. By the adoption of the rotary type sand mold three-dimensional printer, a workbench rotating manner can be used for conducting the sand laying process, the printing process and the workbench descending process at the same time, so that the machining time is shortened, and efficiency is improved. The rotary type sand mold three-dimensional printer is reasonable in design, simple in structure and suitable for optimization design of sand mold three-dimensional printers.

Owner:SHANGHAI JIAO TONG UNIV

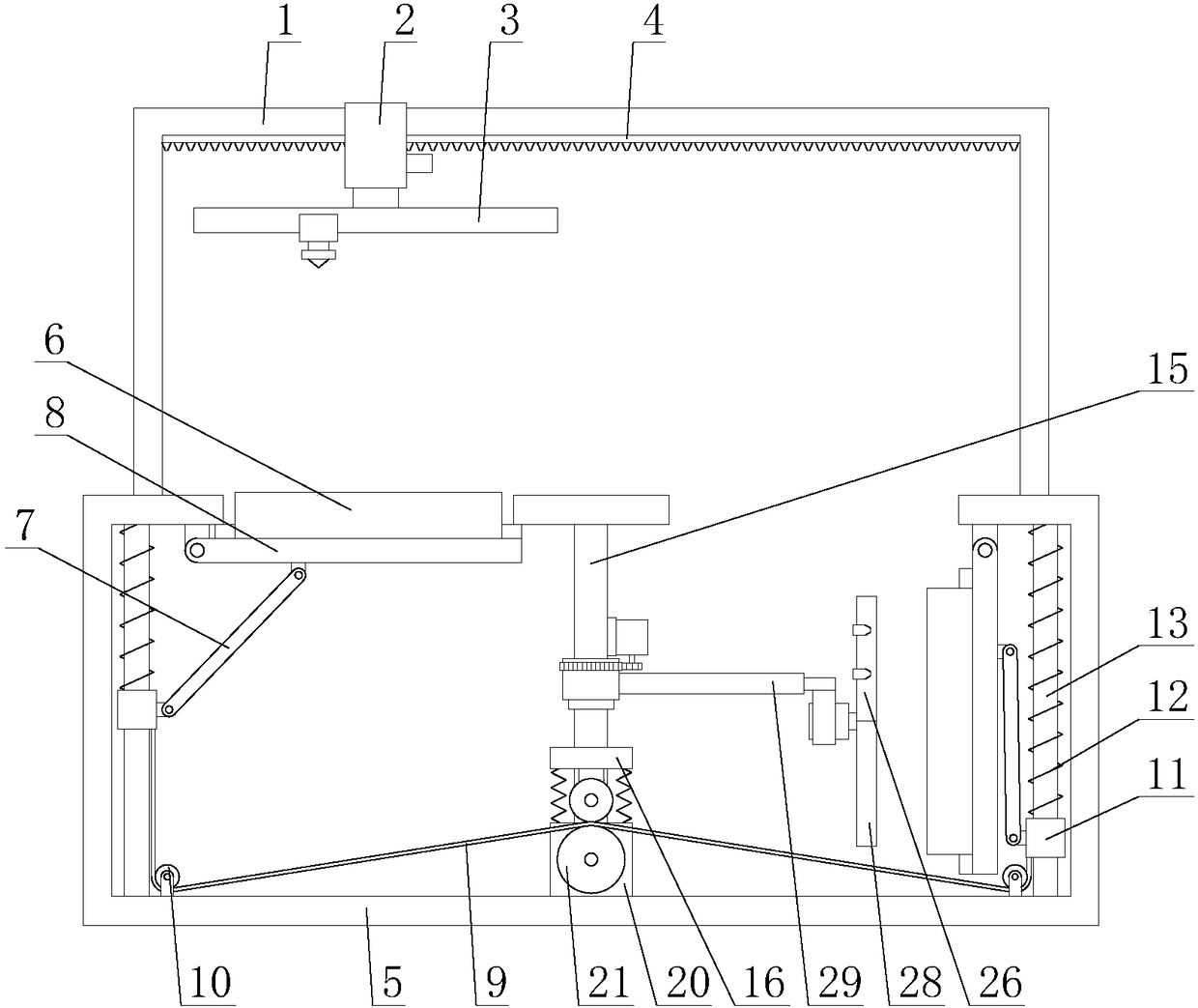

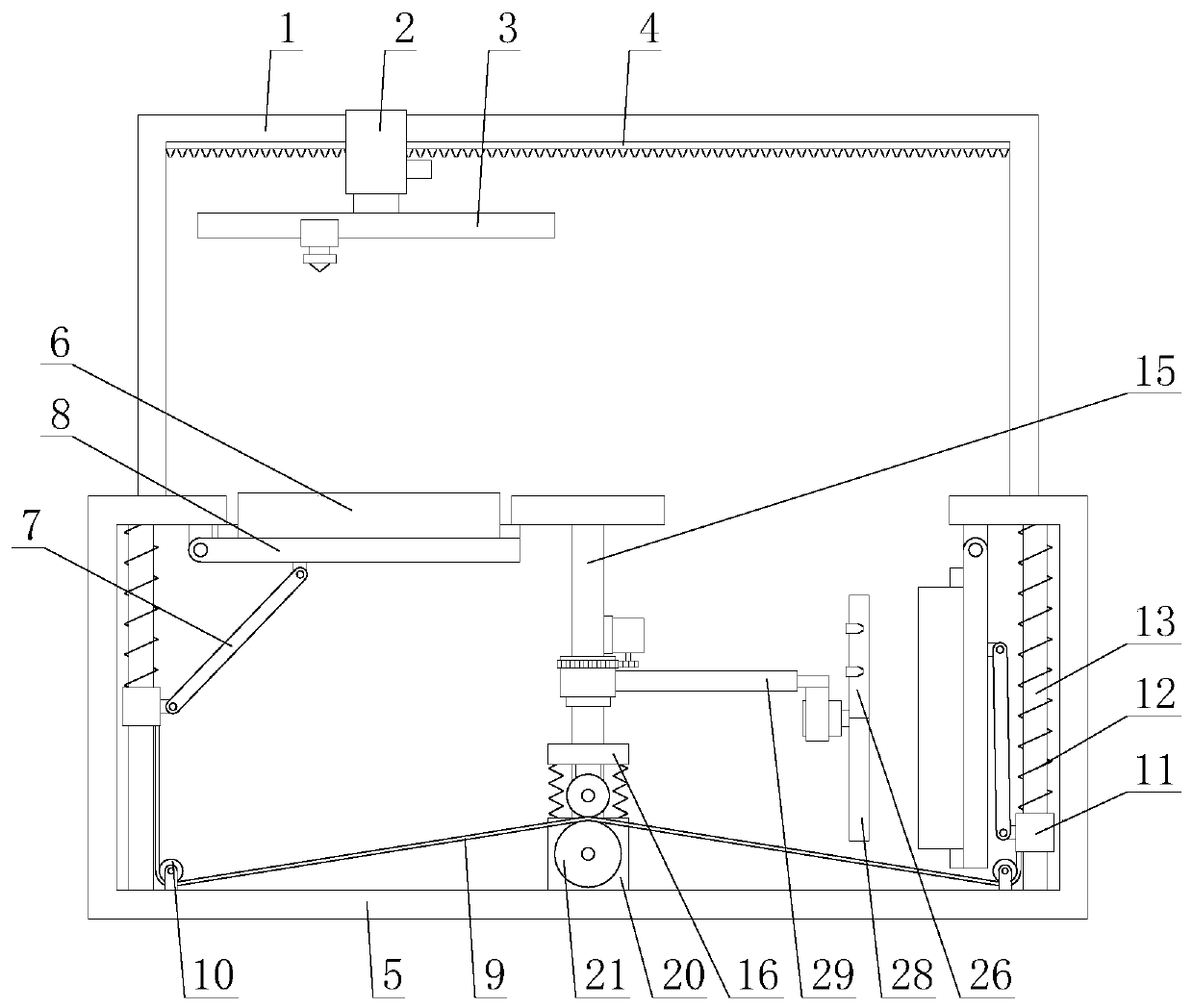

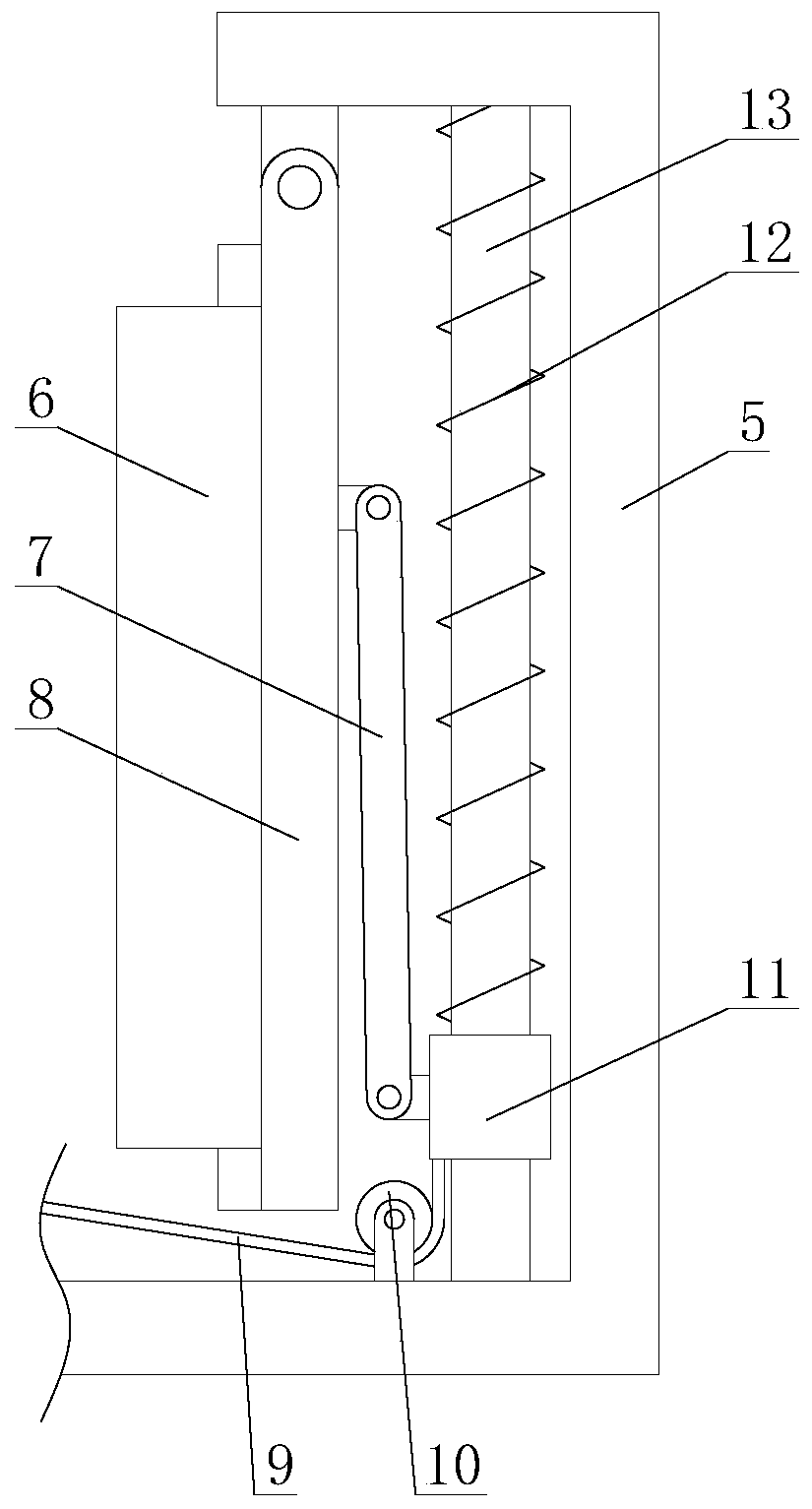

Efficient 3D printer with platform cleaning function based on Internet of things

ActiveCN108262959AImprove printing efficiencyIngenious mechanism designManufacturing driving meansCleaning using toolsInternet of ThingsEngineering

The invention relates to an efficient 3D printer with a platform cleaning function based on Internet of things. The 3D printer comprises a base, a support frame, a printing module, a switching mechanism, a cleaning mechanism and a central control mechanism, wherein the switching mechanism comprises a moving assembly, a power assembly, a transmission belt, a support rod and two switching assemblies; the cleaning mechanism comprises a driving assembly, a position limiting block, a sleeve, an air cylinder, a third motor, a first cleaning brush and a second cleaning brush. The efficient 3D printerwith the platform cleaning function based on Internet of things has the advantages that the switching use of two platforms of the 3D printer is realized through the switching mechanism, so that one platform is in a work state, and meanwhile, the other platform is in a preparation state; therefore the continuous printing of the 3D printer is realized; the printing efficiency of the 3D printer is improved; through the cleaning mechanism, one platform is used, and meanwhile, the other platform is cleaned, so that the cleanness degree of the platform is improved; the printing precision of the 3Dprinter is improved.

Owner:SHAANXI HENGTONG INTELLIGENT MACHINE

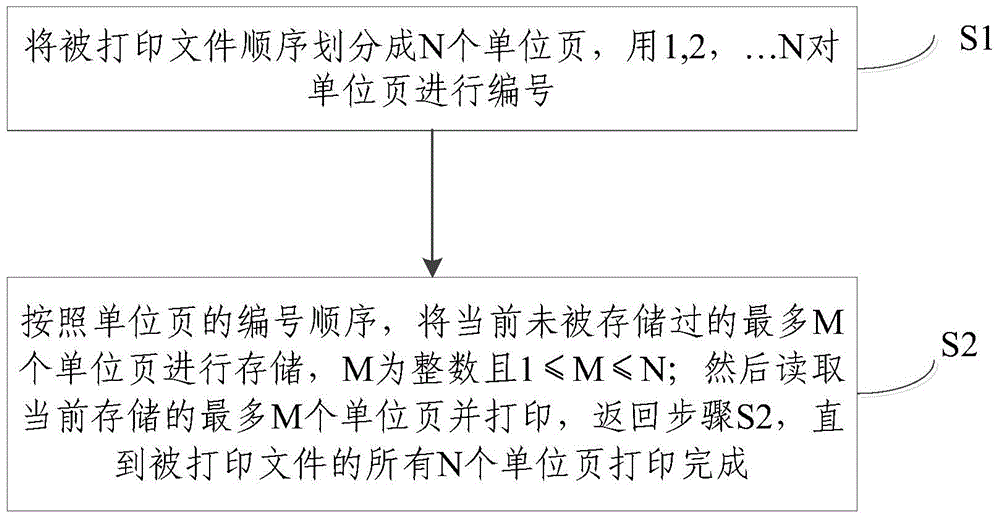

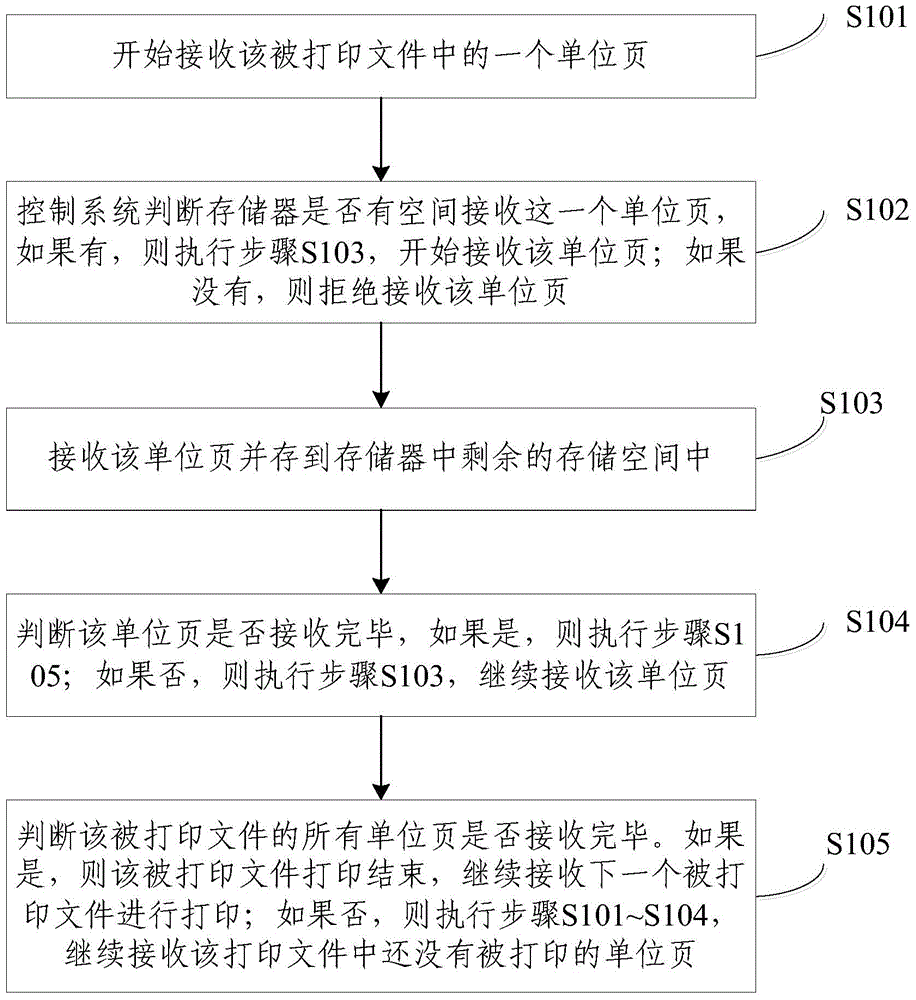

Printing method and device

InactiveCN104417102AAchieve continuous printingOvercome Limiting FlawsOther printing apparatusDatabase

Owner:NEW FOUNDER HLDG DEV LLC +1

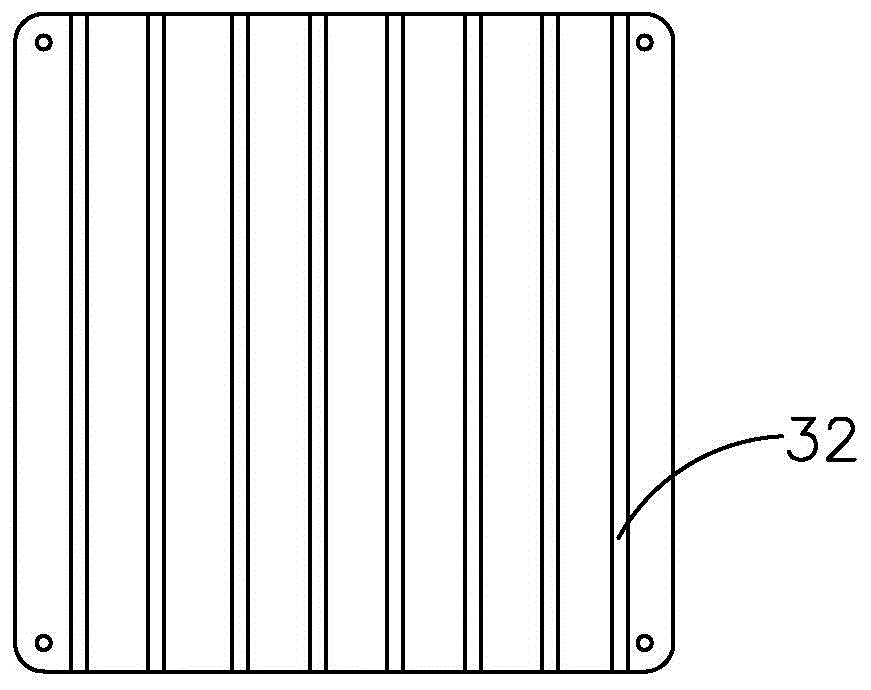

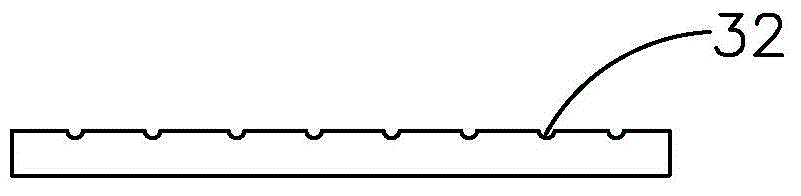

3D printer capable of realizing continuous printing

InactiveCN106313552AAchieve continuous printingAdditive manufacturing apparatus3d printer3D printing

The invention discloses a 3D printer capable of realizing continuous printing, comprising a rack, a spray head assembly, a printing assembly and a regulating assembly; the printing assembly comprises printing flat plates and a ball screw; the ball screw is mounted under the printing flat plates, the input end of the ball screw is connected with a stepping motor, and the output end of the ball screw is provided with slide blocks; and adsorption holes are formed in the slide blocks, are connected with a negative-pressure pipeline and are used for adsorbing and fixing the printing flat plates by virtue of negative pressure. According to the 3D printer provided by the invention, the printing flat plates are adsorbed through the adsorption holes by virtue of the negative pressure in a printing process, and after the spray head assembly finishes 3D printing on one printing flat plate, the printing flat plate moves along the axis direction of the ball screw under the action of the stepping motor, and the other printing flat plate is enabled to be located below the spray head assembly, so that continuous printing is realized; and the vacuum of the adsorption holes located under the printing flat plate finishing printing is closed, so that the printing flat plate can be directly taken away by working staff.

Owner:CHENGDU MEILYU SCI & TECH CO LTD

Photocuring 3D printer and printing method

InactiveCN109049685AAchieve continuous printingReduce printing timeManufacturing enclosures3D object support structures3d printEngineering

The invention relates to a photocuring 3D printer and a printing method. The photocuring 3D printer comprises a resin pool assembly, a component for accommodating a resin pool film and fixedly arranged relative to a resin pool, and a transparent adhesive layer; the resin pool assembly comprises the resin pool film and the resin pool for accommodating the resin; and the two sides of the adhesive layer are bonded to the resin pool film and the component. The photocuring 3D printer effectively solves the problem about the long printing cycle time, shortens the printing time and improves the printing efficiency.

Owner:GOLD ARRAY TECH BEIJING LLC

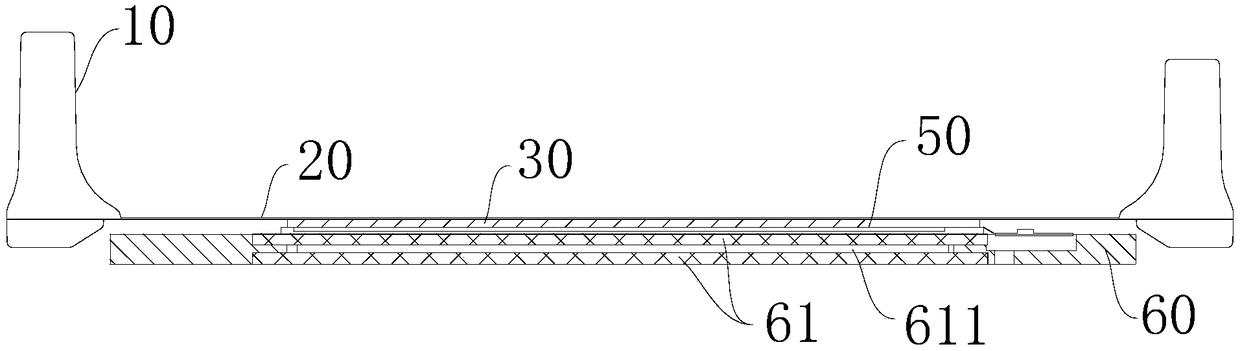

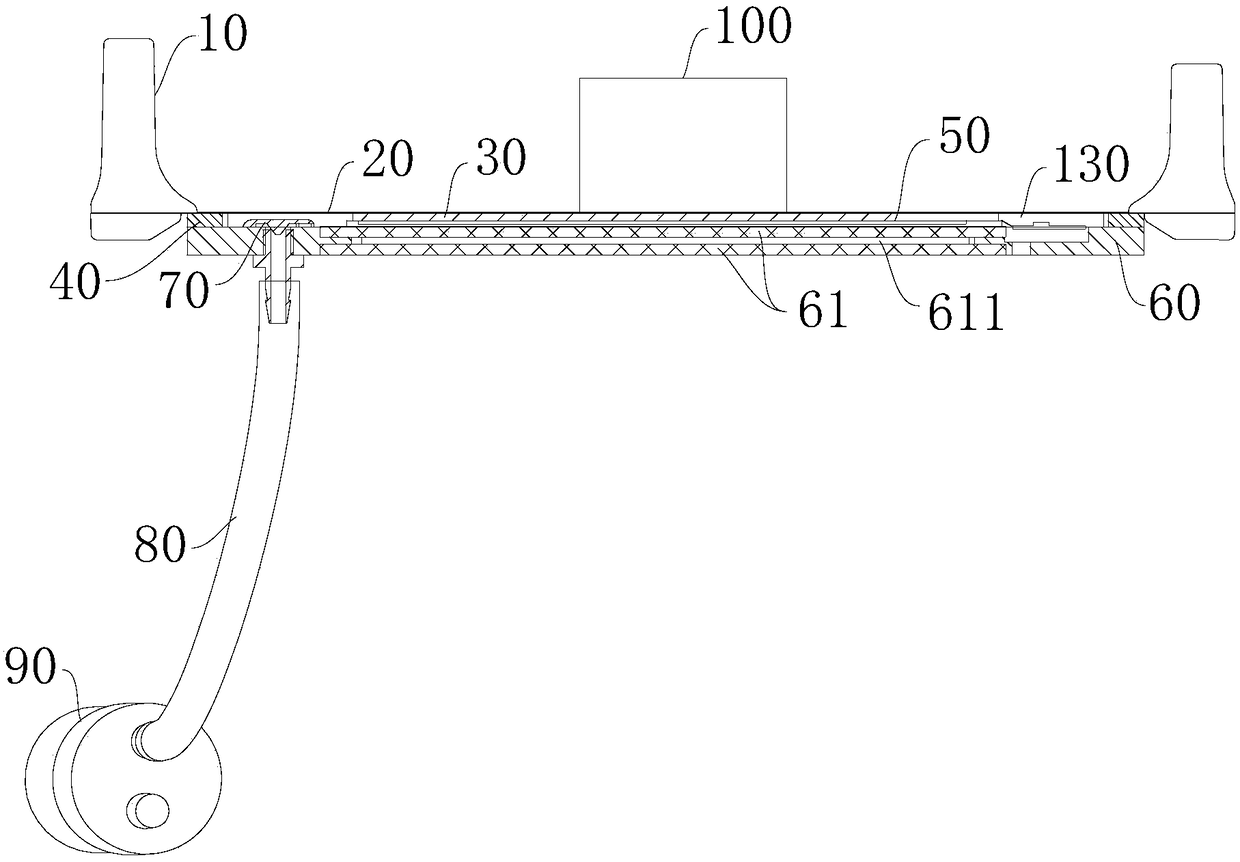

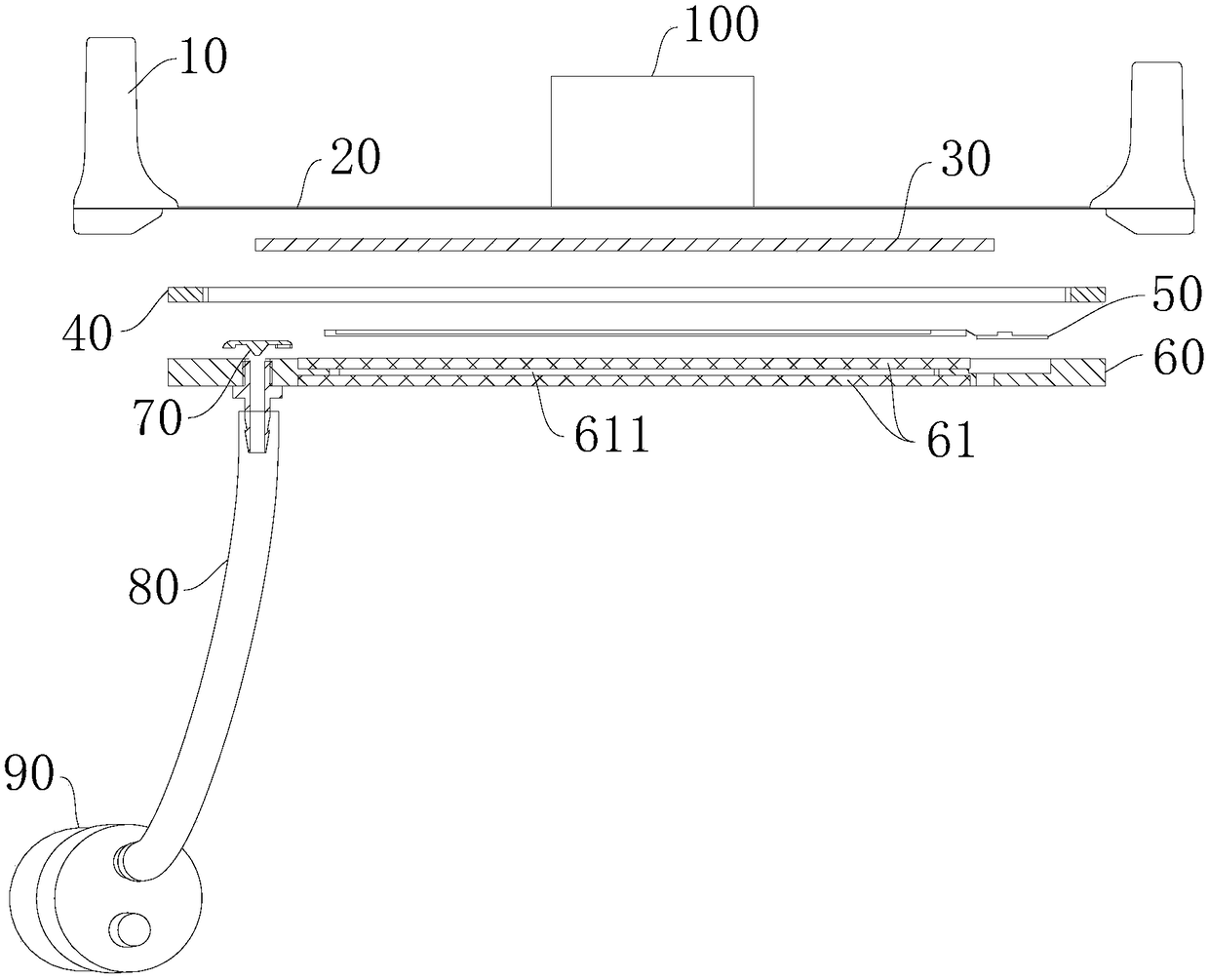

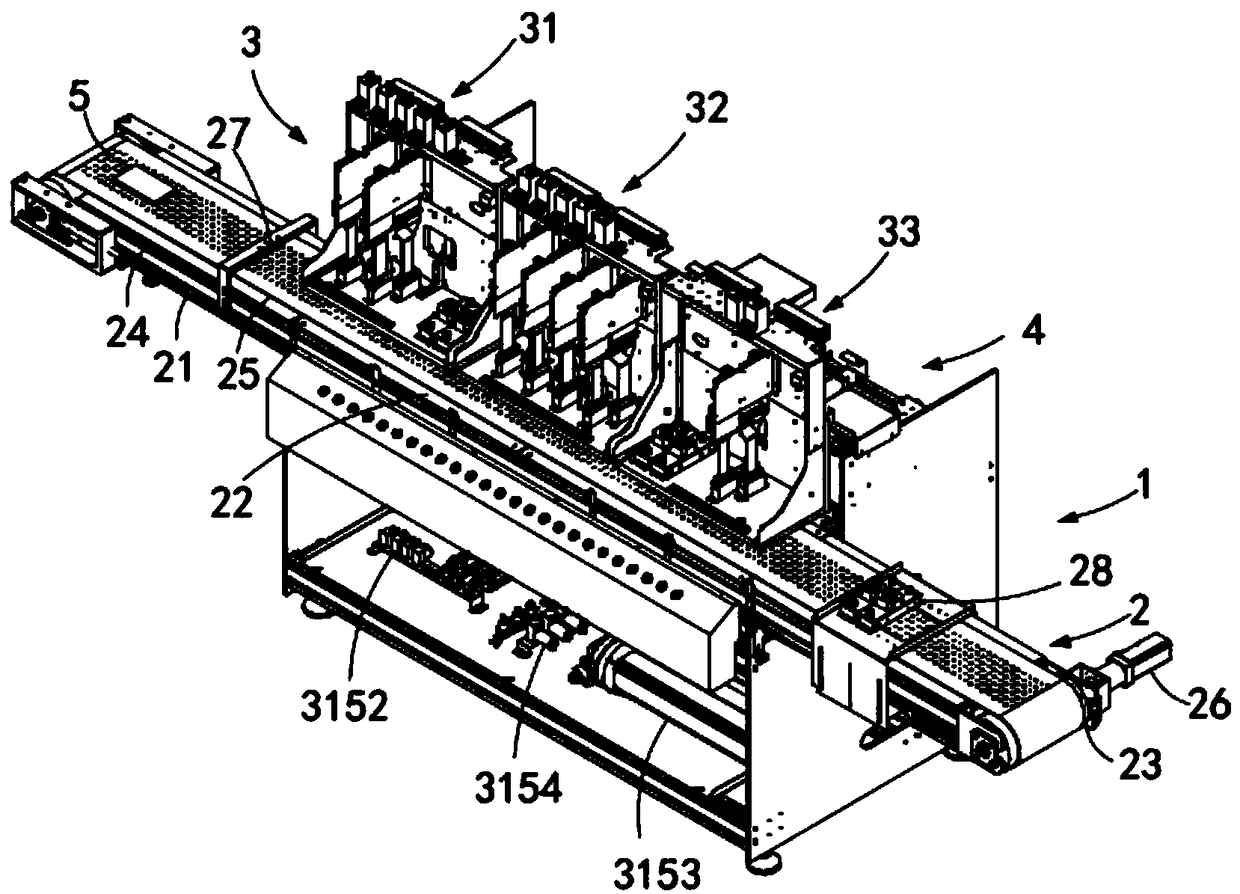

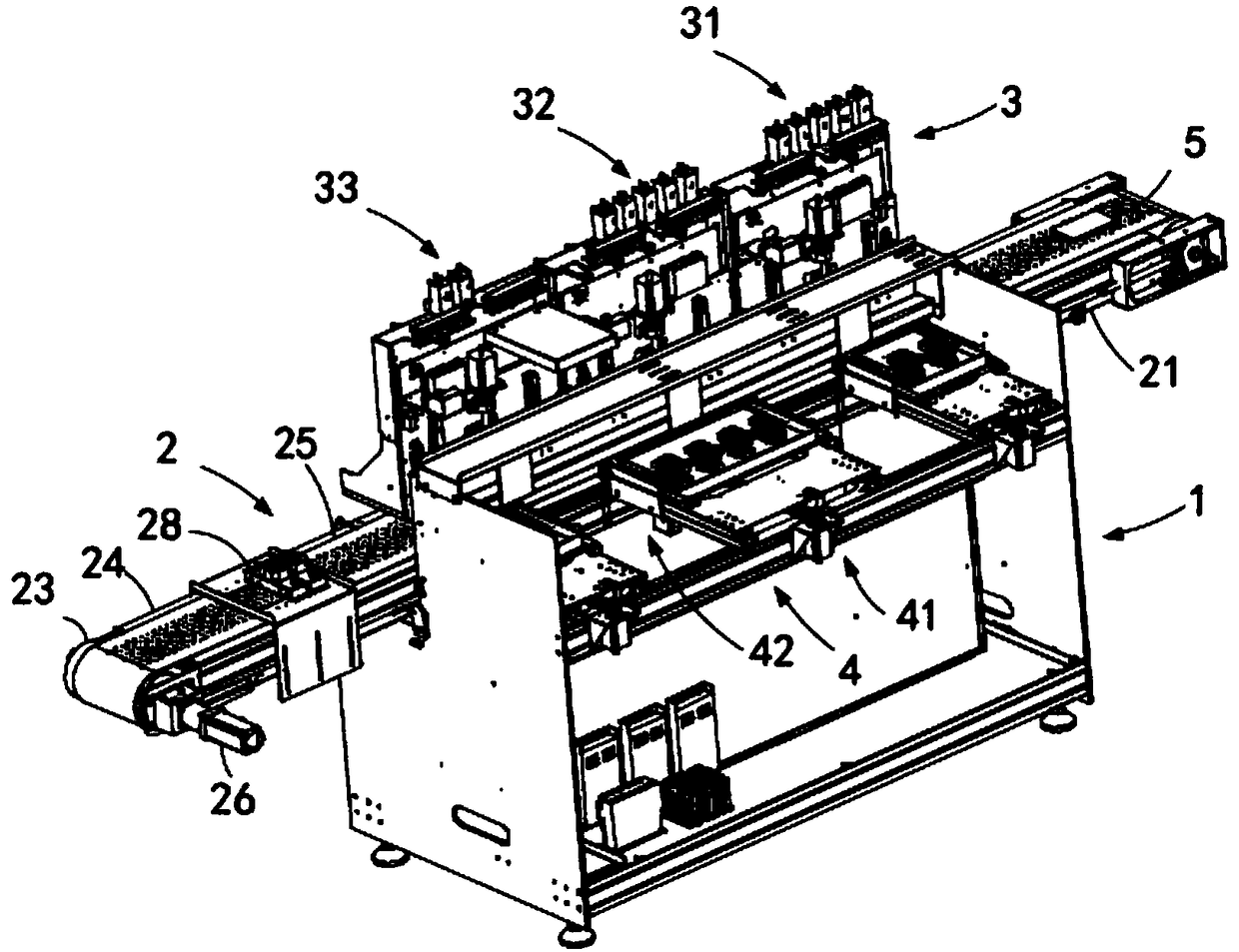

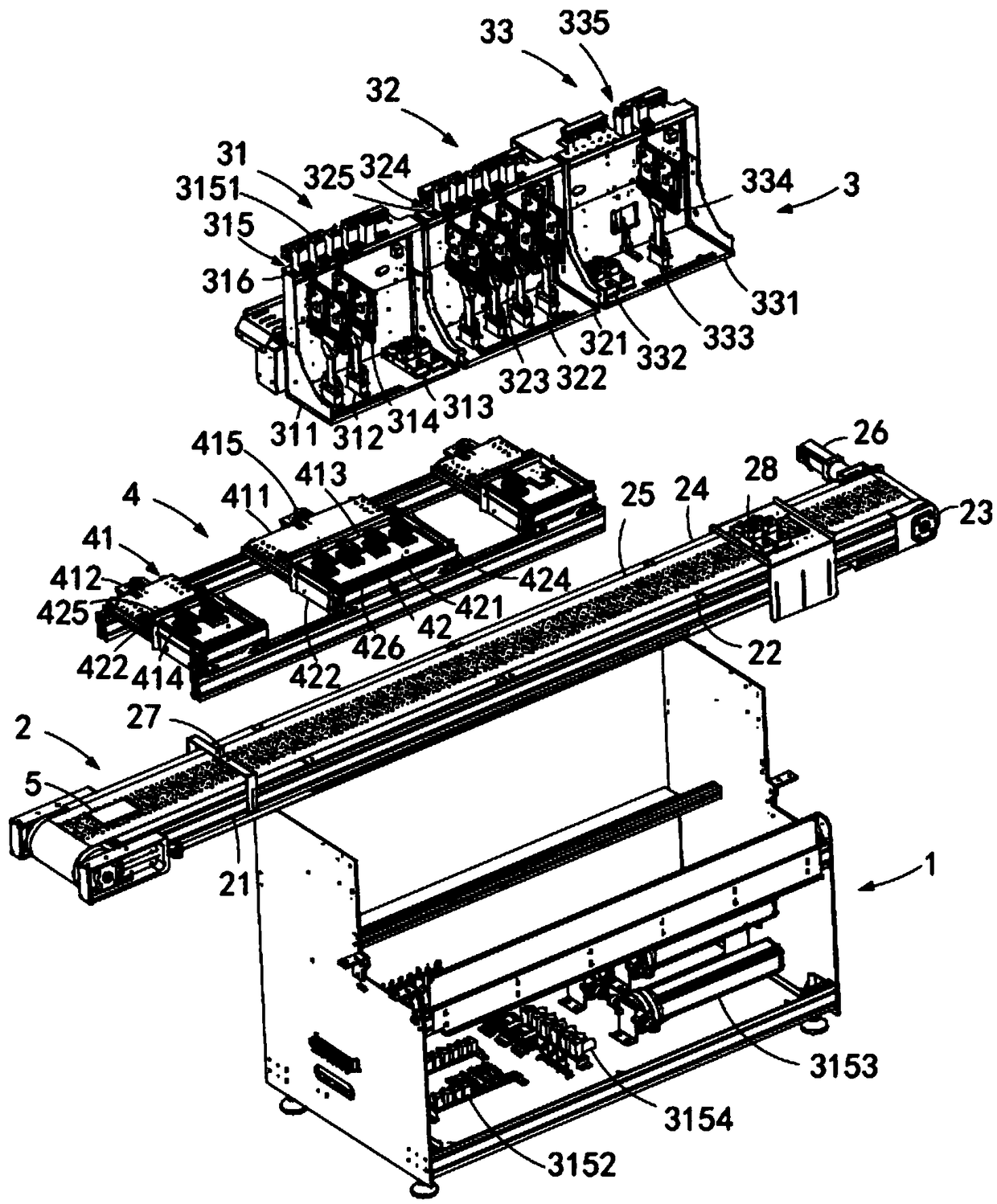

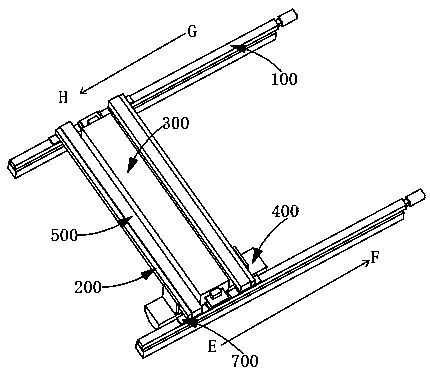

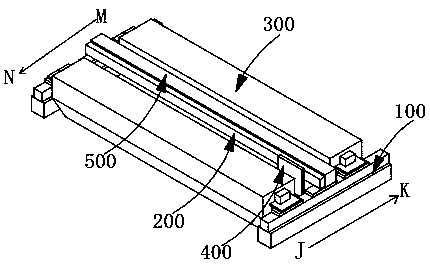

Continuous type platform printing device

InactiveCN102529425APrint fitAchieve continuous printingTypewritersOther printing apparatusEngineeringContinuous type

The invention provides a continuous type platform printing device, which is provided with a platform for supporting printed media, can achieve continuous printing, and is particularly suitable for printing fabrics. The continuous type platform printing device comprises a frame and a supporting seat which is slidingly arranged on the frame along the longitudinal direction, wherein the supporting seat is provided with an ink stack, an ink absorption seat and guide rails which extend along the horizontal direction, a printing trolley which is provided with a printing head is slidingly arranged on the guide rails, and the supporting seat is provided with a trolley driving device which drives the printing trolley to move along the guide rails. The frame is provided with at least two sliding rails which extend along the longitudinal direction, the upper surfaces of the sliding rails are slidingly provided with a printing platform of the printed media, and the printing trolley is arranged above the printing platform. The lower portion of the printing platform is provided with a lifting device which is used for lifting the printing platform to be separated from the sliding rails.

Owner:南京德众数码科技有限公司

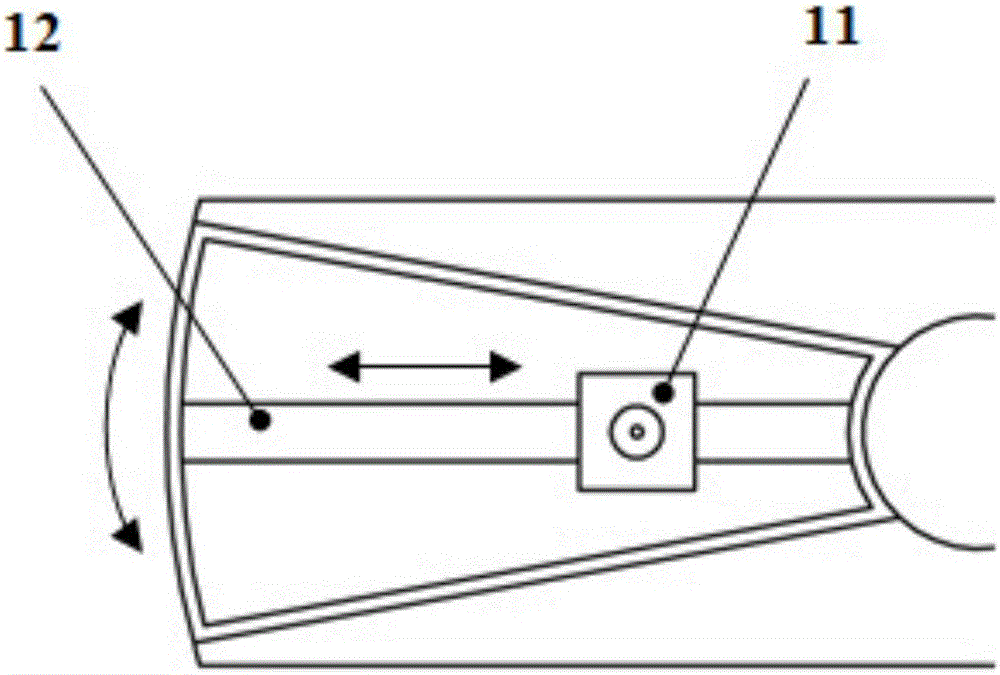

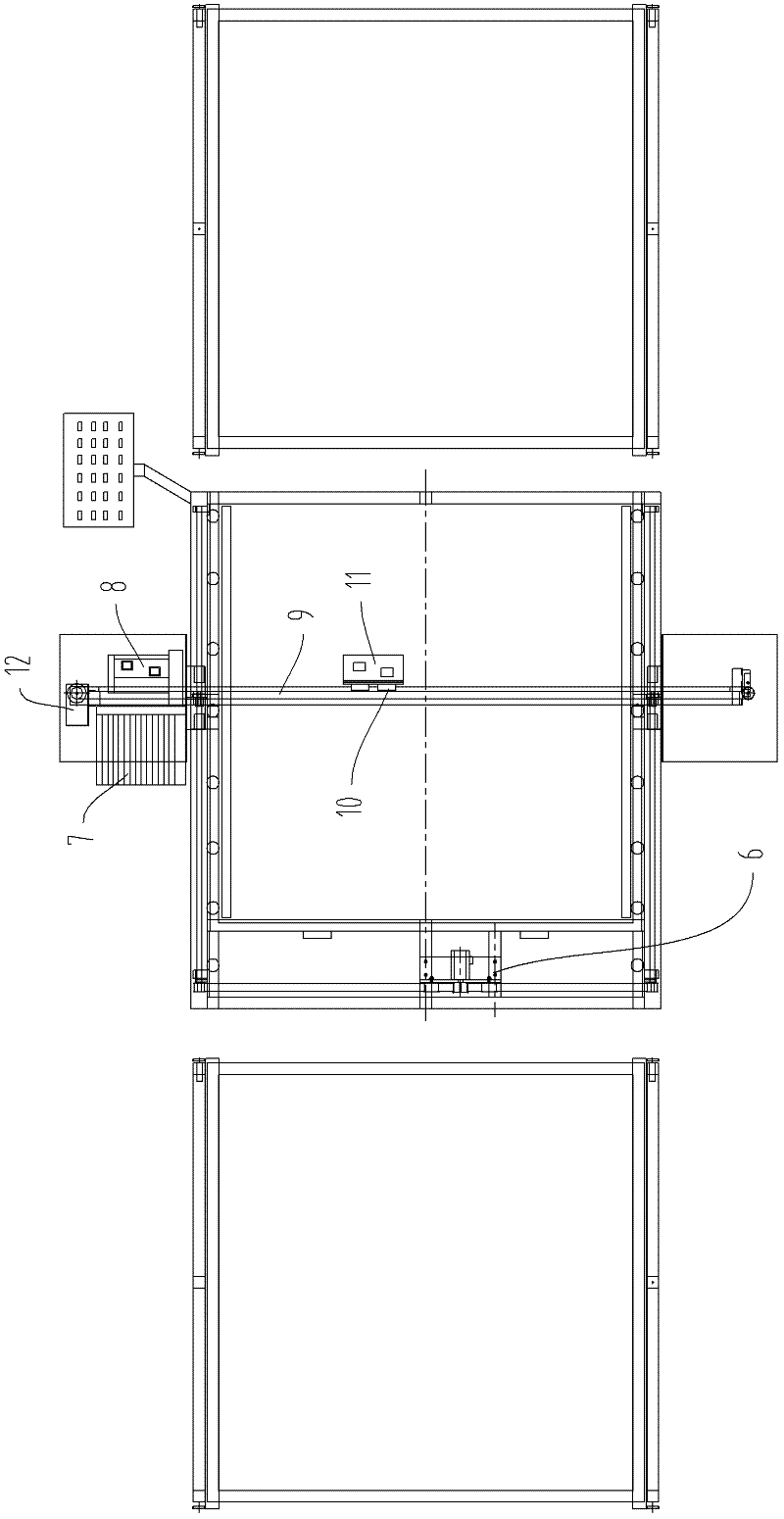

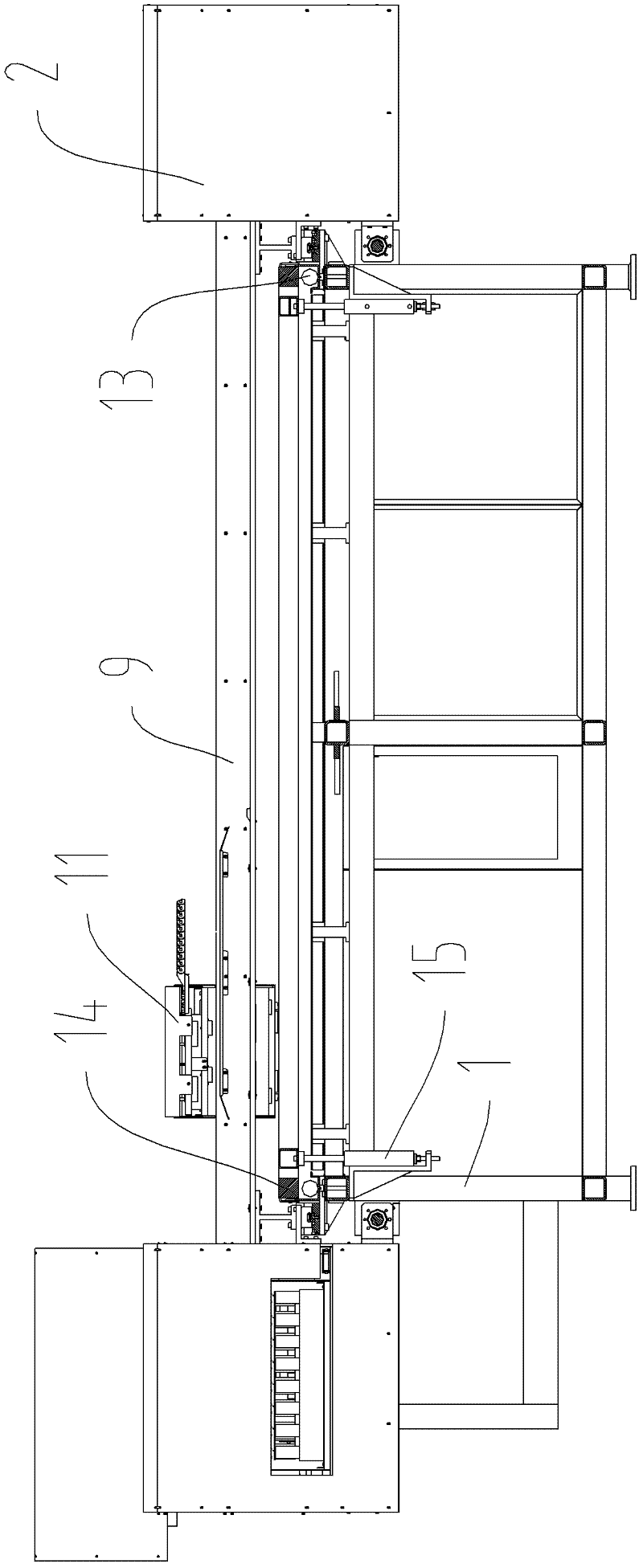

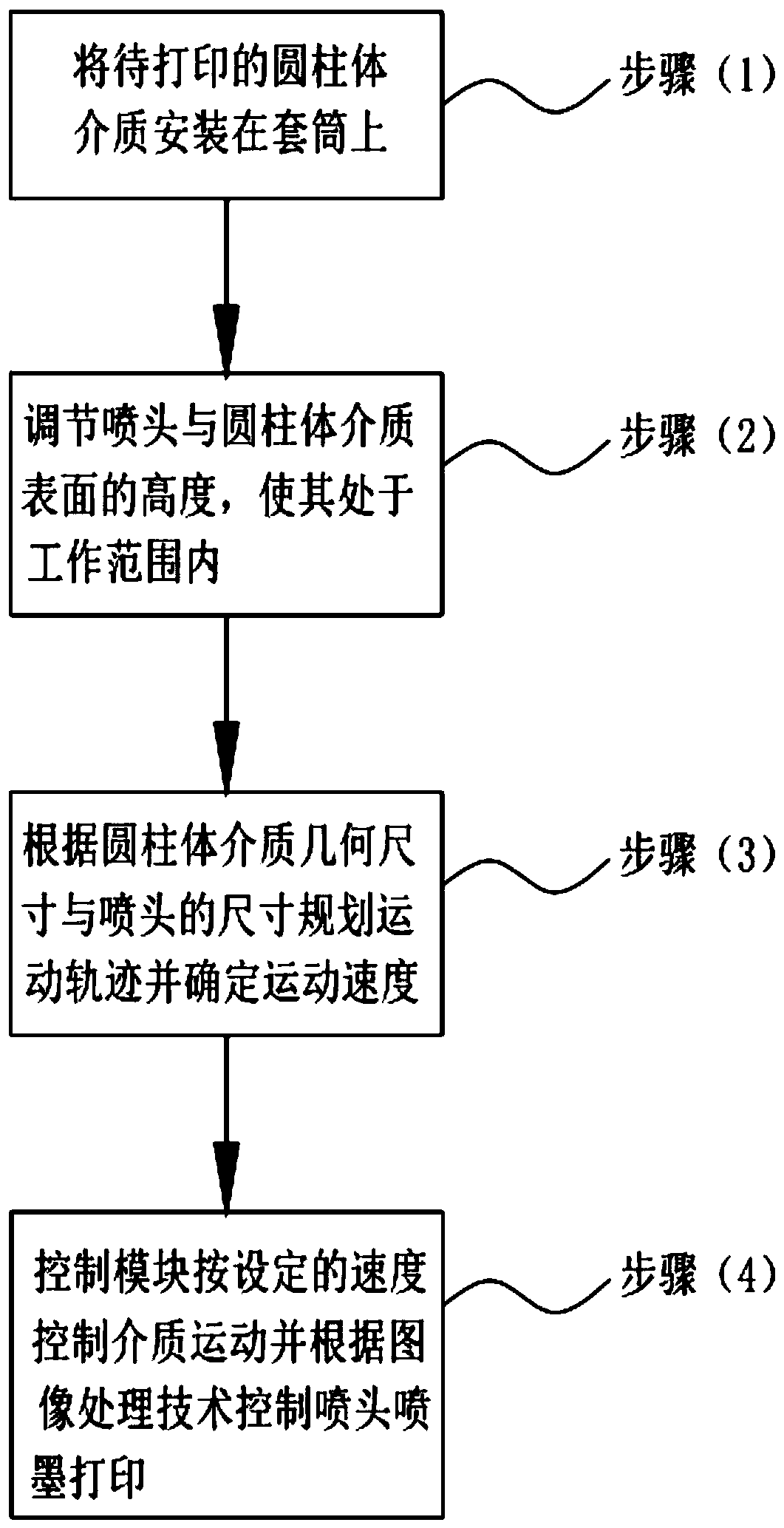

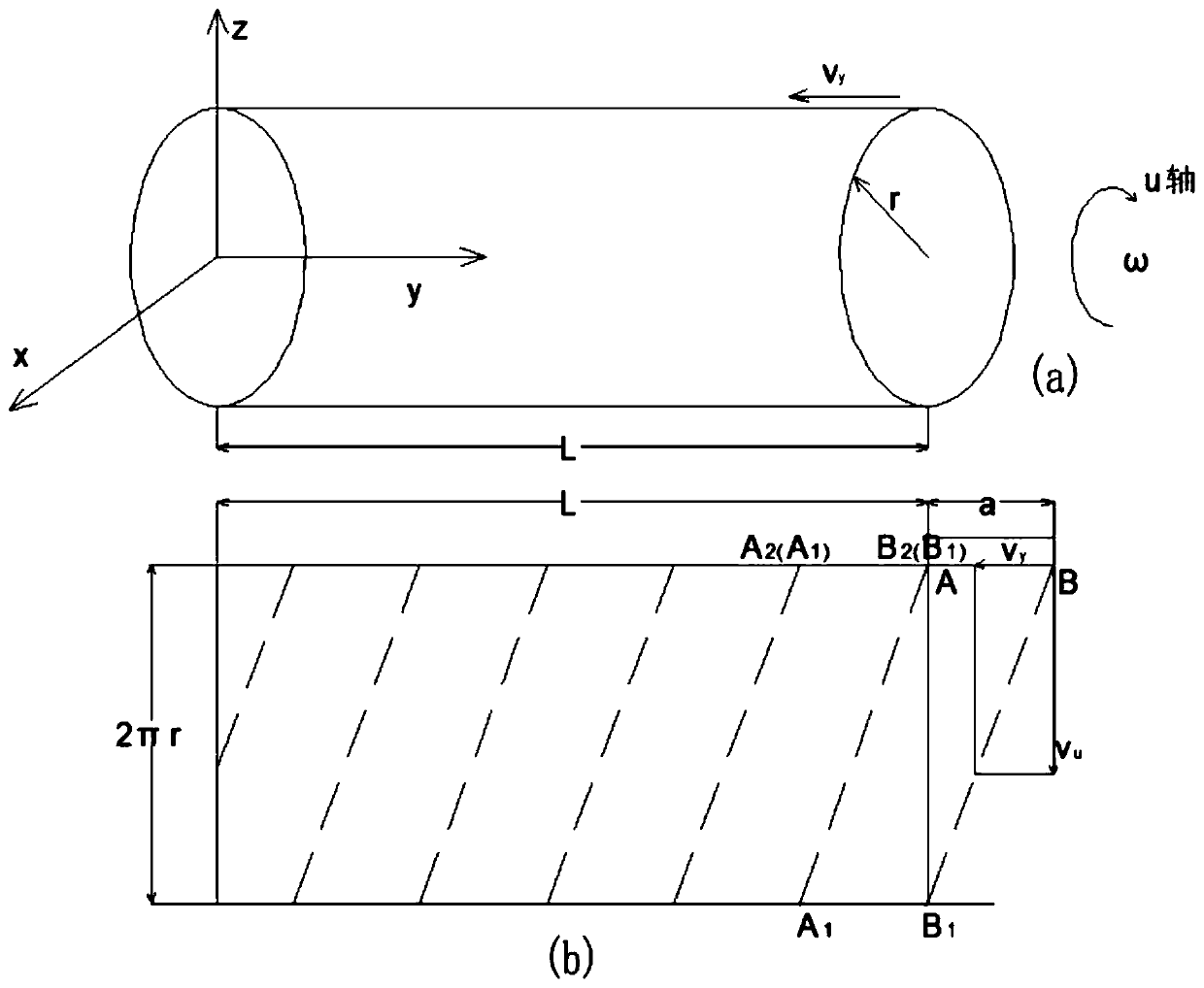

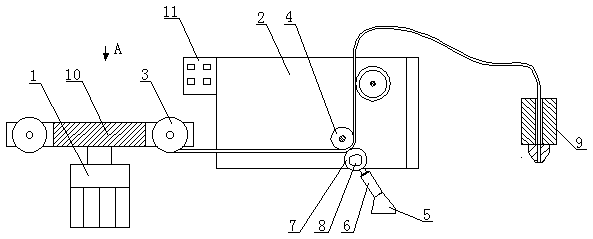

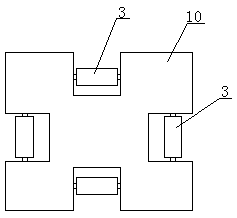

Continuous printing device and method for outer surfaces of cylinders

InactiveCN110254055AReduce non-printing timeImprove printing efficiencyTypewritersPower drive mechanismsImaging processingComputer module

The invention discloses a continuous printing device and method for the outer surfaces of cylinders and belongs to the technical field of digital ink-jet printing. The continuous printing device comprises a cylinder medium mounting module, a jet nozzle adjusting module, a jet nozzle control module, a master control module and a movement control module. A non-contact type digital ink-jet printing technology is chosen and used in cooperation with the technologies of movement control, image processing and the like, an intermittent scanning printing mode in the existing ink-jet printing method is changed, movement paths are designed by applying the movement control and image processing technologies according to the geometric features of the cylinders, non-intermittent continuous printing is realized on the surfaces of the cylinders, the one-step forming of 360 degree printing is realized on the outer surfaces of the cylinders, and the printing efficiency is greatly increased.

Owner:佛山市科自智能系统技术有限公司

One-time imaging flatbed printer

InactiveCN108128041AContinuous printingIncrease productivityTypewritersOther printing apparatusEngineeringElectrical and Electronics engineering

The invention discloses a one-time imaging flatbed printer. The one-time imaging flatbed printer comprises a rack, a transmission device, a printing device and a moisturizing and cleaning device. Thetransmission device is arranged on the rack. The printing device is arranged on the rack and corresponds to the transmission device. The moisturizing and cleaning device is arranged on the rack and corresponds to the printing device. The printing device comprises a first printing mechanism, a second printing mechanism and a third printing mechanism. The first printing mechanism, the second printing mechanism and the third printing mechanism are arranged on the rack side by side and correspond to the transmission device. According to the one-time imaging flatbed printer, a novel printing form is adopted, a printing head is fixed, an object to be printed is driven by a conveyor belt to pass from the portion below the printing head, imaging can be achieved through one-time printing, continuous printing can be realized, and the production efficiency is improved.

Owner:GUANGZHOU NUOCAI DIGITAL PROD CO LTD

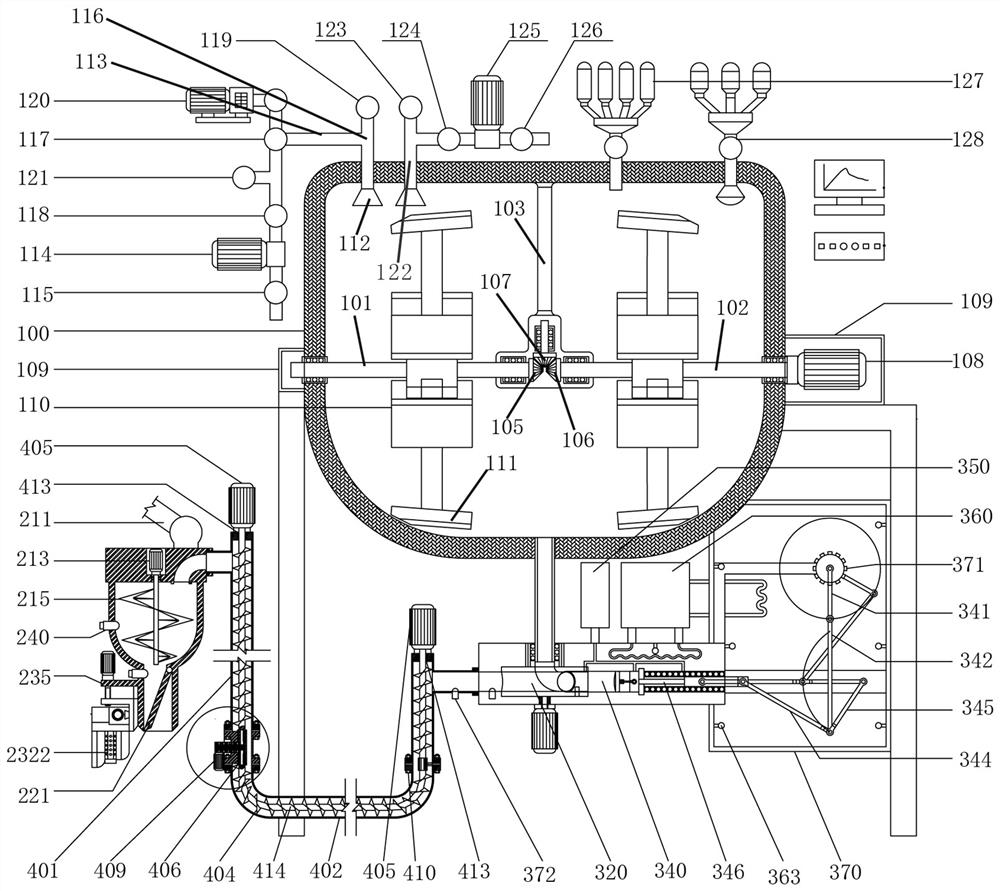

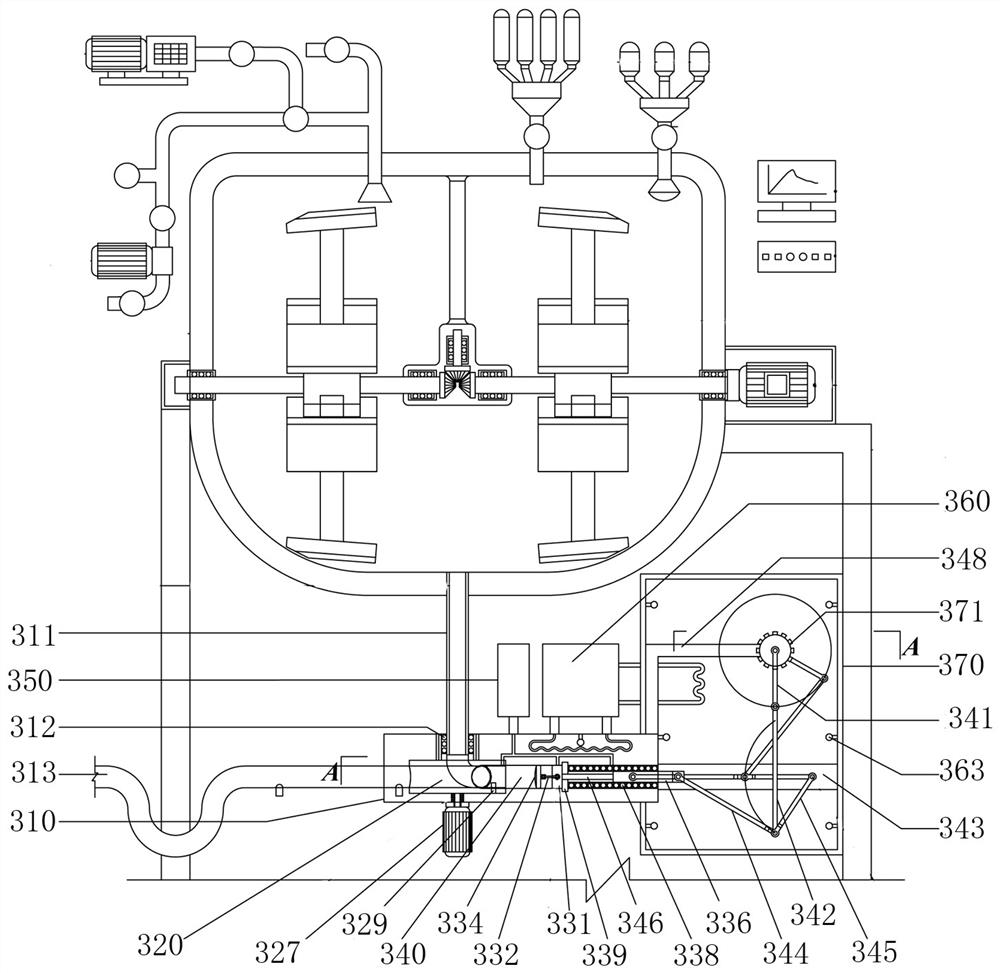

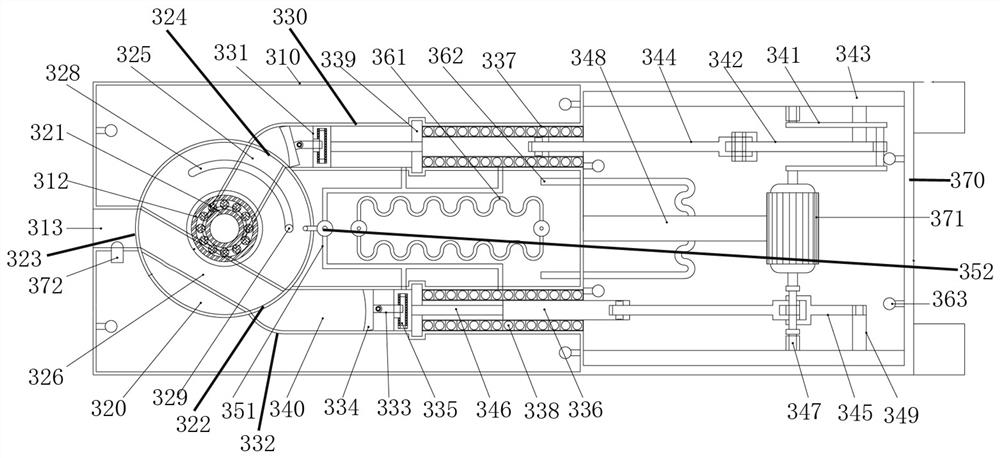

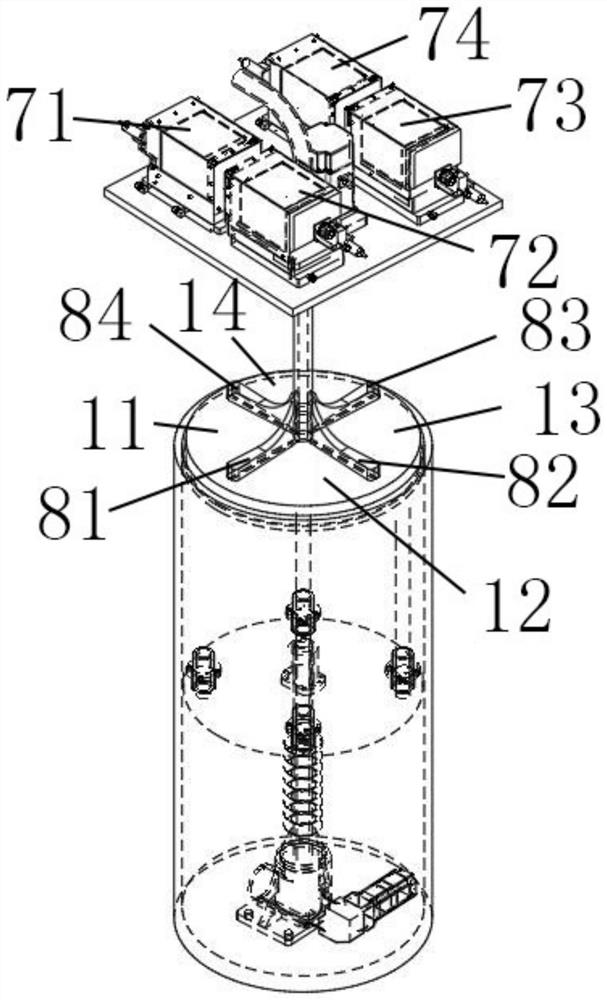

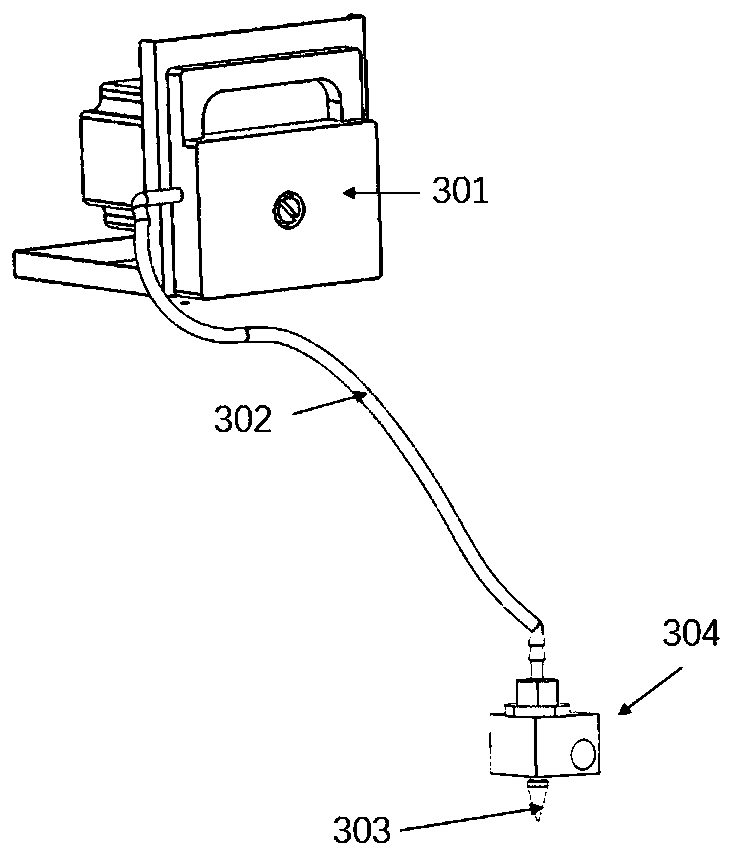

Feeding system for 3D printing of ultra-high performance concrete

PendingCN112829040AImprove homogeneityImprove compactnessAdditive manufacturing apparatusFeeding arrangmentsComputer printingStructural engineering

The invention belongs to the technical field of 3D printing of ultra-high performance concrete. A feeding system for 3D printing of ultra-high performance concrete comprises a stirring tank, a vacuumizing unit, a main stirring unit, a feeding unit, a conveying pump and a 3D printer nozzle, wherein the stirring tank is of a sealed structure and is supported by a main body rack; the vacuumizing unit is connected to the top of the stirring tank and is used for vacuumizing the stirring tank; the main stirring unit is used for stirring materials in the stirring tank; the feeding unit is arranged at the top of the stirring tank and is used for feeding the materials into the stirring tank; the feeding end of the conveying pump is connected with the bottom of the stirring tank through a material receiving pipe; and the discharging end of the conveying pump is connected with the 3D printer nozzle. The feeding system is reasonable in structural design, environmentally friendly, efficient, high in intelligent degree and green degree and more suitable for 3D printing of ultra-high performance concrete (UHPC).

Owner:ZHENGZHOU UNIV

Special 3D printing equipment for printing hollow cylindrical component and printing method thereof

PendingCN114042937AGuaranteed uptimeRealize zoned laserAdditive manufacturing apparatusIncreasing energy efficiencyGalvanometerEngineering

The invention relates to special 3D printing equipment for printing a hollow cylindrical component and a printing method thereof. The equipment comprises a printing device and a powder laying device, the printing device comprises a device shell and a printing substrate, and the printing substrate is located in the device shell and moves up and down in the device shell; the powder laying device is hung above the printing device, and the powder laying device comprises a platform whole body, a powder feeding pipeline, a plurality of laser galvanometers and a plurality of scrapers; the plurality of scrapers are rotationally connected with the whole platform; and the distances between the lower end faces of the scrapers and the printing substrate are different. According to the invention, the plurality of rotatable scrapers and the corresponding number of laser galvanometers are adopted, the printing substrate is divided into a plurality of printing areas, partitioned laser and printing are realized, stepped rotary powder spreading is realized by setting the continuous change of the distance between each scraper and the printing substrate, the printing efficiency can be improved by about 16 times, and finally the product quality is improved.

Owner:苏州三峰激光科技有限公司

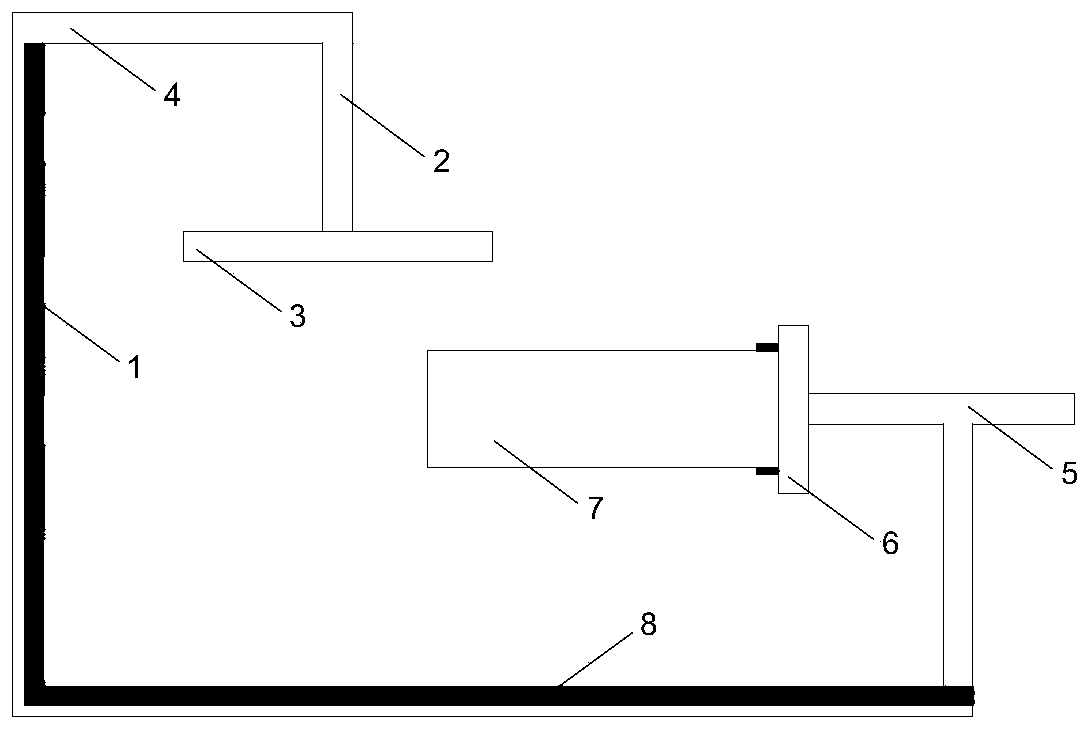

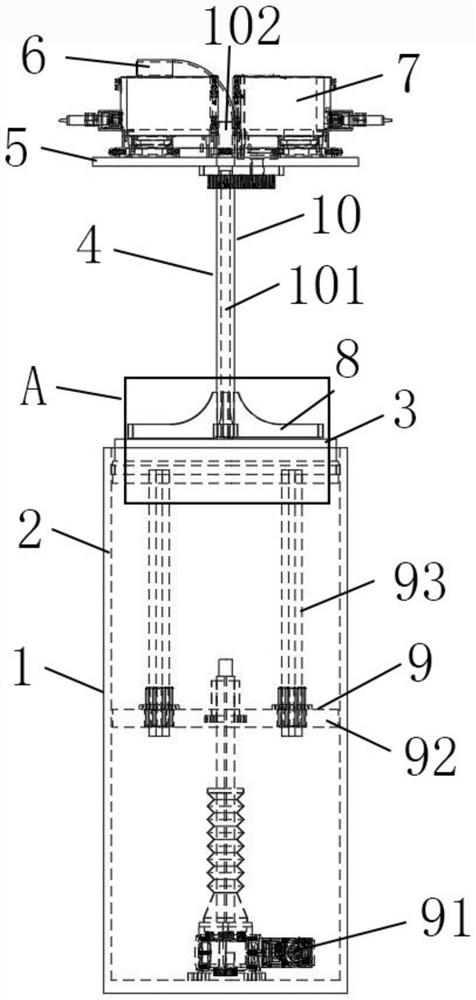

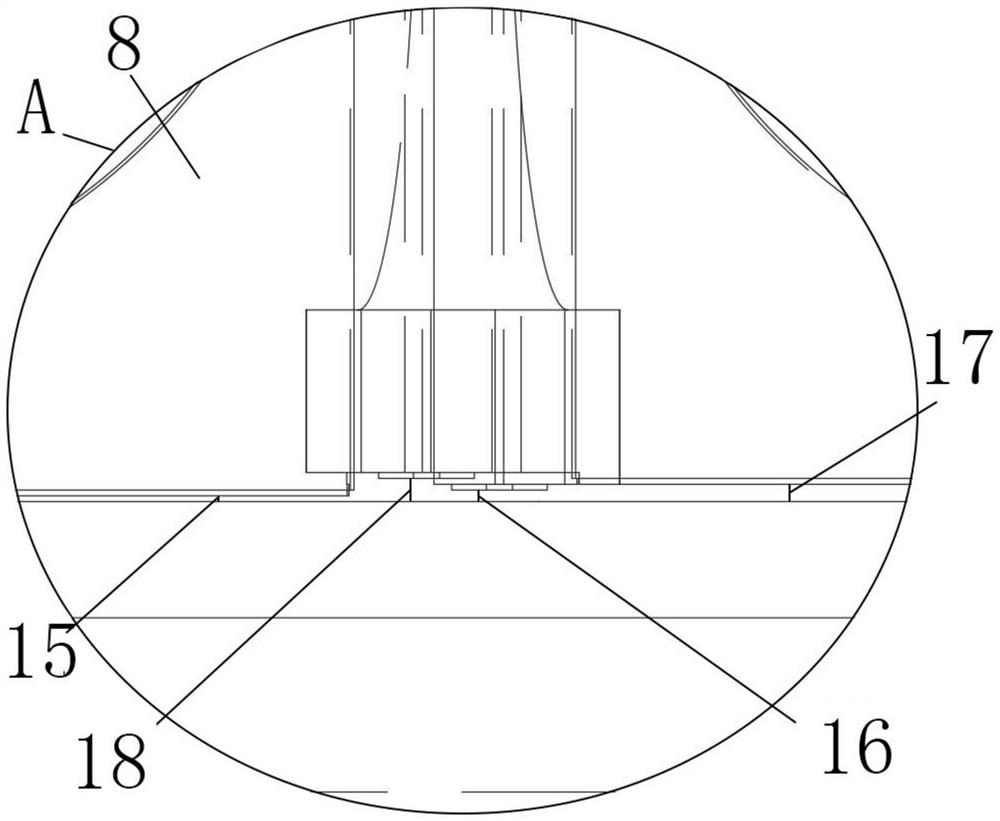

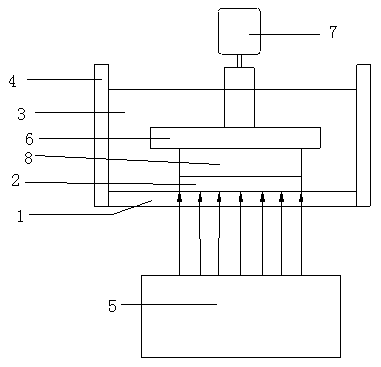

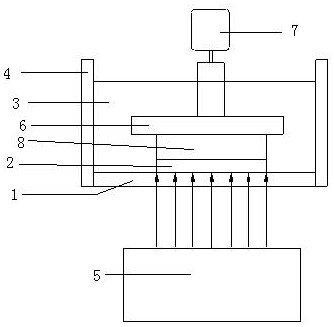

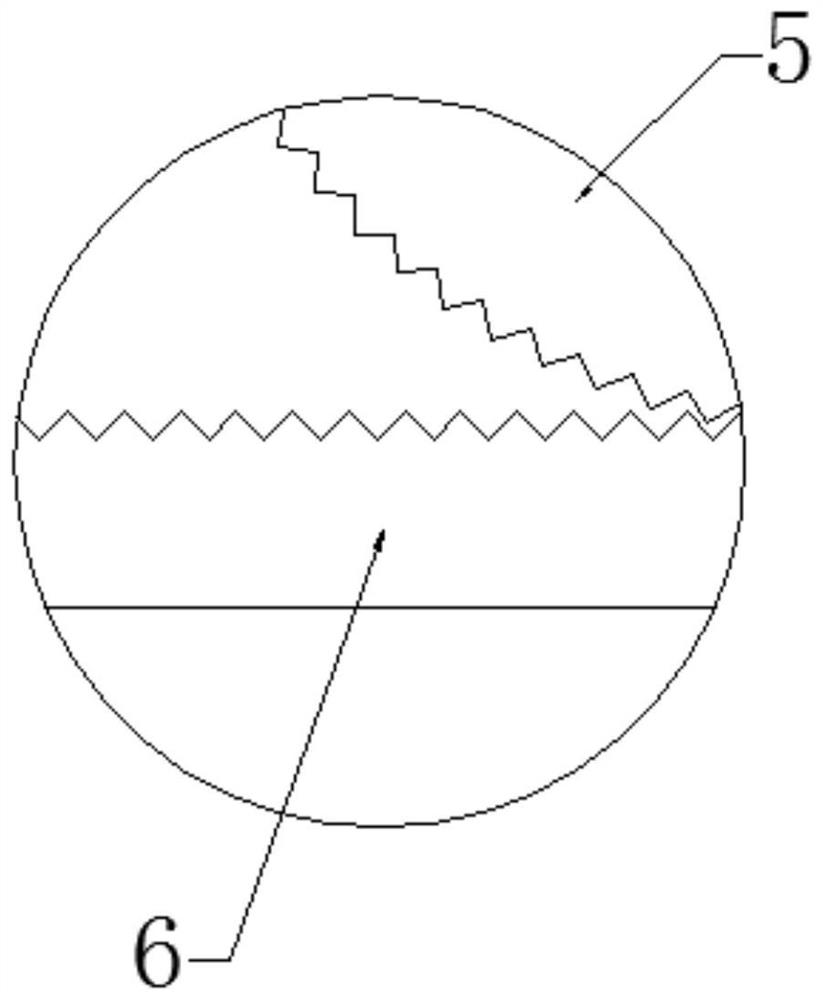

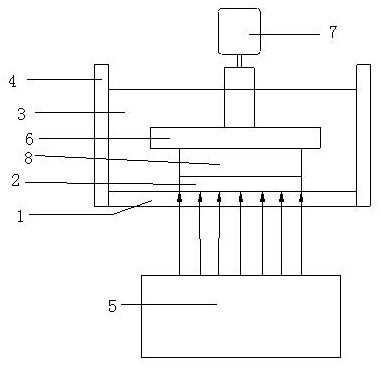

Continuous 3D (three-dimensional) printing system

ActiveCN109228315AAvoid stickingAvoid the refill stepAdditive manufacturing apparatus3D object support structuresEngineeringPhotocatalytic degradation

The invention provides a continuous 3D (three-dimensional) printing system. The continuous 3D printing system comprises a light transmission window (1), a non-curing layer (2), a photosensitive resin(3), a material tank (4), optical equipment (5), an object carrying stage (6), a motor (7) and a curing product (8), wherein the light transmission window (1) is positioned at the bottom part of the material tank (4); the photosensitive resin (3) is arranged in the material tank (4), and contains titanium dioxide nanoparticles and components which can be degraded into a blocking agent by visible light catalysis. The continuous 3D printing system has the beneficial effects that the non-curing layer is formed in the light transmission window in the printing process, the curing body mechanical stripping and photosensitive resin refilling process of the traditional 3D printing method can be effectively avoided, the continuous printing effect is realized, and the printing speed is higher than the printing speed of the traditional photosensitive resin 3D method, and is more than 20 times higher than the printing speed of the traditional 3D method; in the printing process, the thickness of the light transmission window is 3 to 50mm, the easiness in cracking and deformation in the printing process is avoided under the function of mold plugging force, the precision of the printed product ishigher, and the printing speed is comparable with the latest CLIP technique and reaches 500mm / h.

Owner:TAIZHOU POLYTECHNIC COLLEGE

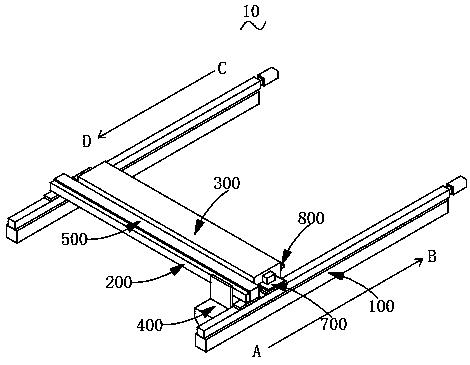

Printing assembly and 3D printing equipment

InactiveCN111169004AAchieve continuous printingImprove printing efficiencyAdditive manufacturing apparatus3D object support structuresComputer printingIndustrial engineering

The invention relates to a printing assembly and 3D printing equipment. The 3D printing equipment comprises the printing assembly. The printing assembly comprises discharging guide rails symmetricallyarranged, a plurality of printing guide rails, a plurality of discharging mechanisms and a plurality of printing mechanisms, wherein each of the printing guide rails and each of the discharging mechanisms are arranged between the two symmetrical discharging guide rails; and one printing mechanism is arranged on at least one printing guide rail in a sliding manner. The printing assembly and the 3Dprinting equipment can realize synchronous reciprocating motion of the discharging mechanisms and the printing mechanisms along the discharging guide rails to realize continuous printing, so that theprinting efficiency can be effectively improved and the equipment occupied space can be greatly saved at the same time.

Owner:KOCEL INTELLIGENT FOUNDRY IND INNOVATION CENT CO LTD

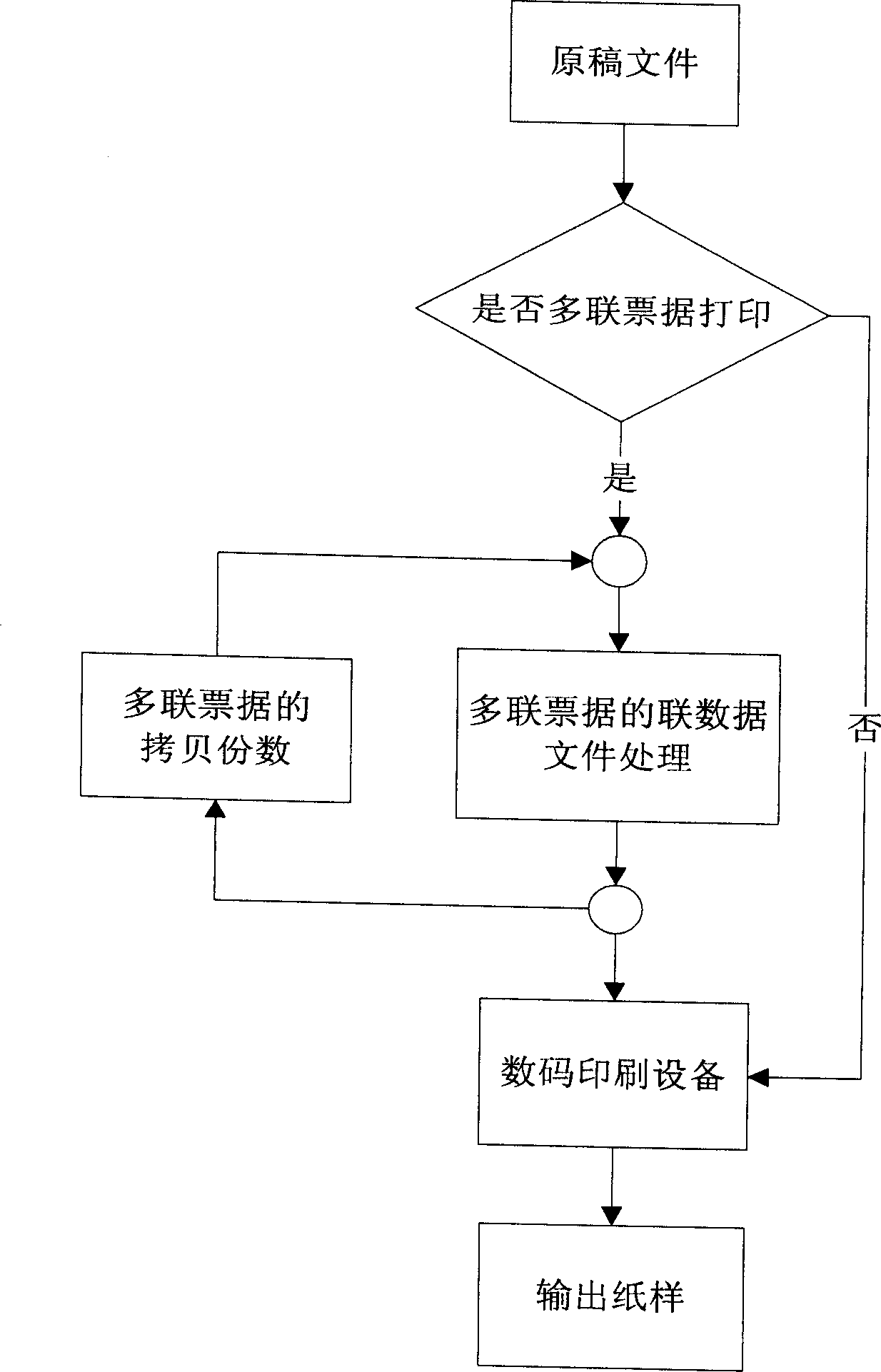

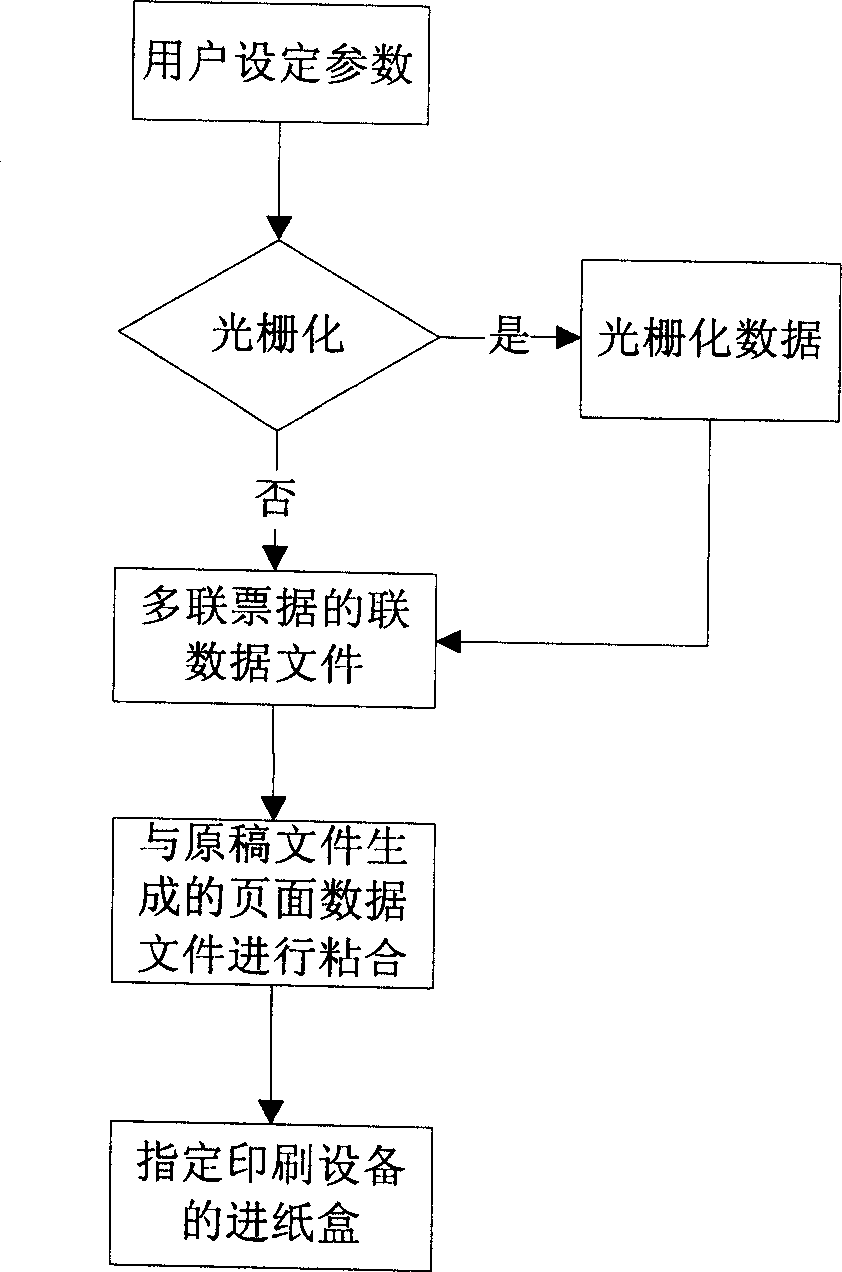

Method and system for continuously printing multiple part bills

InactiveCN1908887ALow costImprove work efficiencyVisual presentation using printersDigital output to print unitsDigital printingData file

The related continual printing method for multiple-bill comprises: unlike to current technology, generating every data file for multiple-bill according to user selected control parameters, bonding the data file with original page data file to generate new complete data file; outputting the whole bill file for one time by digital printing device. This invention reduces cost and improves efficiency.

Owner:BEIJING FOUNDER ELECTRONICS CO LTD +1

Three-dimensional continuous printing platform device

ActiveCN108000878AAchieve continuous printingManufacturing platforms/substratesIncreasing energy efficiencyEngineeringSecondary layer

Owner:福建万象三维科技有限公司

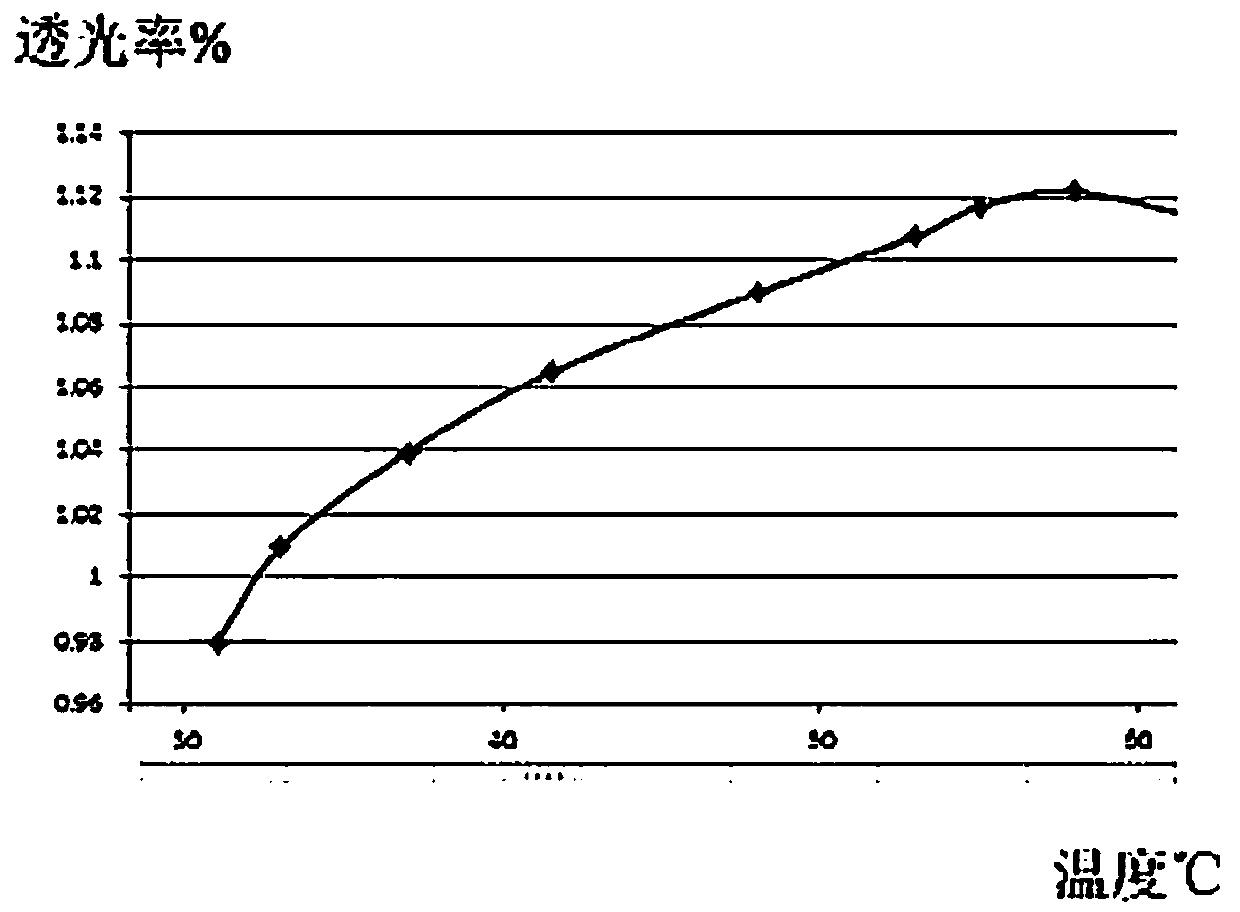

A fast 3D printing system

ActiveCN109228316BAvoid mechanical strippingAvoid the refill processAdditive manufacturing apparatus3D object support structuresPhysical chemistryMaterials science

Owner:TAIZHOU POLYTECHNIC COLLEGE

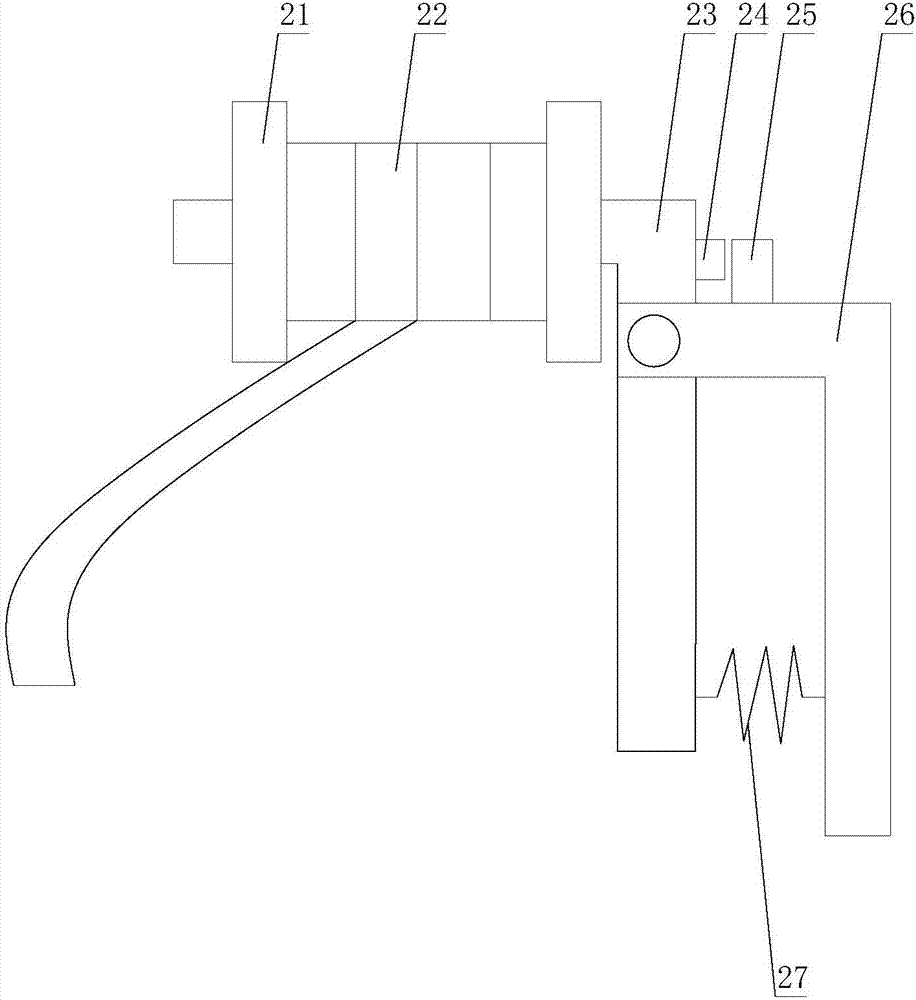

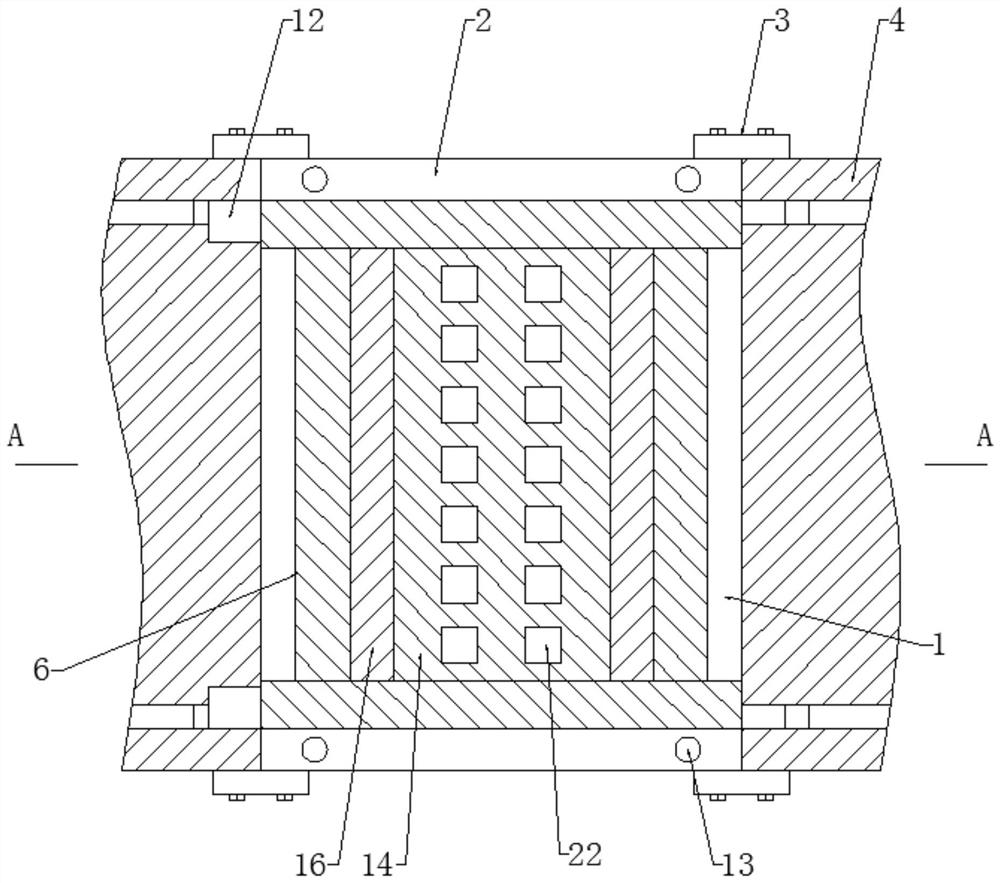

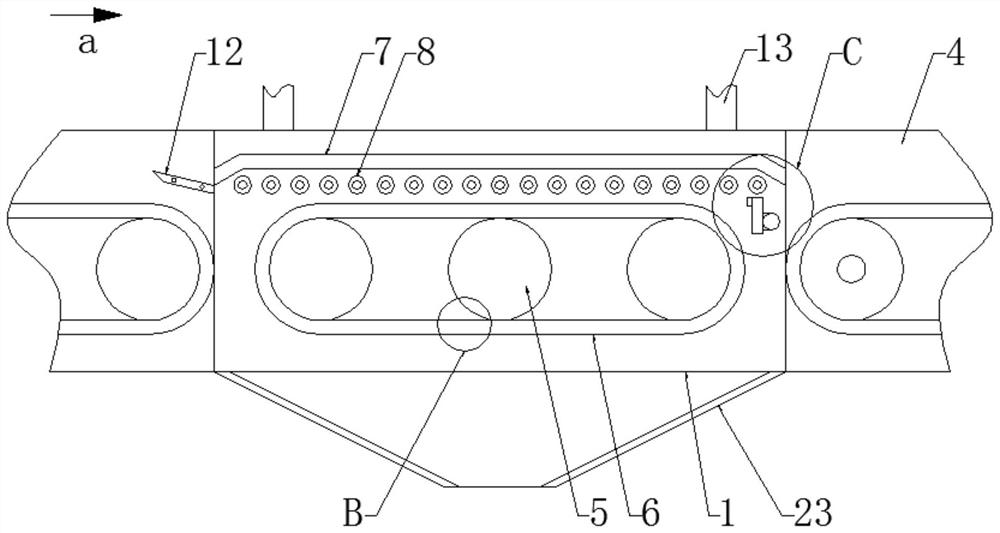

Winding mechanism and cutting cable 3D printing device thereof

ActiveCN111958963AAvoid inconvenienceImprove efficiencyAdditive manufacturing apparatusFilament handlingEngineeringMachining

The invention discloses a winding mechanism and a cutting cable 3D printing device thereof. The cutting cable 3D printing device comprises a printing module, a guiding mechanism and a winding mechanism, wherein an inner pipe is printed by taking molten plastic as a raw material, and meanwhile, an inner cavity of the inner pipe is filled with a petroleum explosive; and through the guide mechanism,the printed inner pipe continuously extends in the axial direction in a continuous downward moving mode so as to obtain a long inner pipe; and meanwhile, it is guaranteed that the inner pipe and the printing end face of the printing module do not move so as to guarantee the printing precision; and the winding mechanism is used for winding the printed inner pipe, thereby realizing machining of thelong inner pipe. The inner pipe is printed in a 3D mode, meanwhile, the inner pipe is filled with the petroleum explosive, then the outer pipe is manufactured independently, finally, the inner pipe isinstalled in the outer pipe, the outer pipe is stretched, and the inner pipe is clamped by the outer pipe. The efficiency of the winding mechanism is far higher than the machining efficiency of a traditional cutting cable, the cross section of the obtained cutting cable is standard, and therefore, the cutting cable is better in performance and is a revolutionary breakthrough of the cutting cablemanufacturing technology.

Owner:CHONGQING VOCATIONAL INST OF ENG

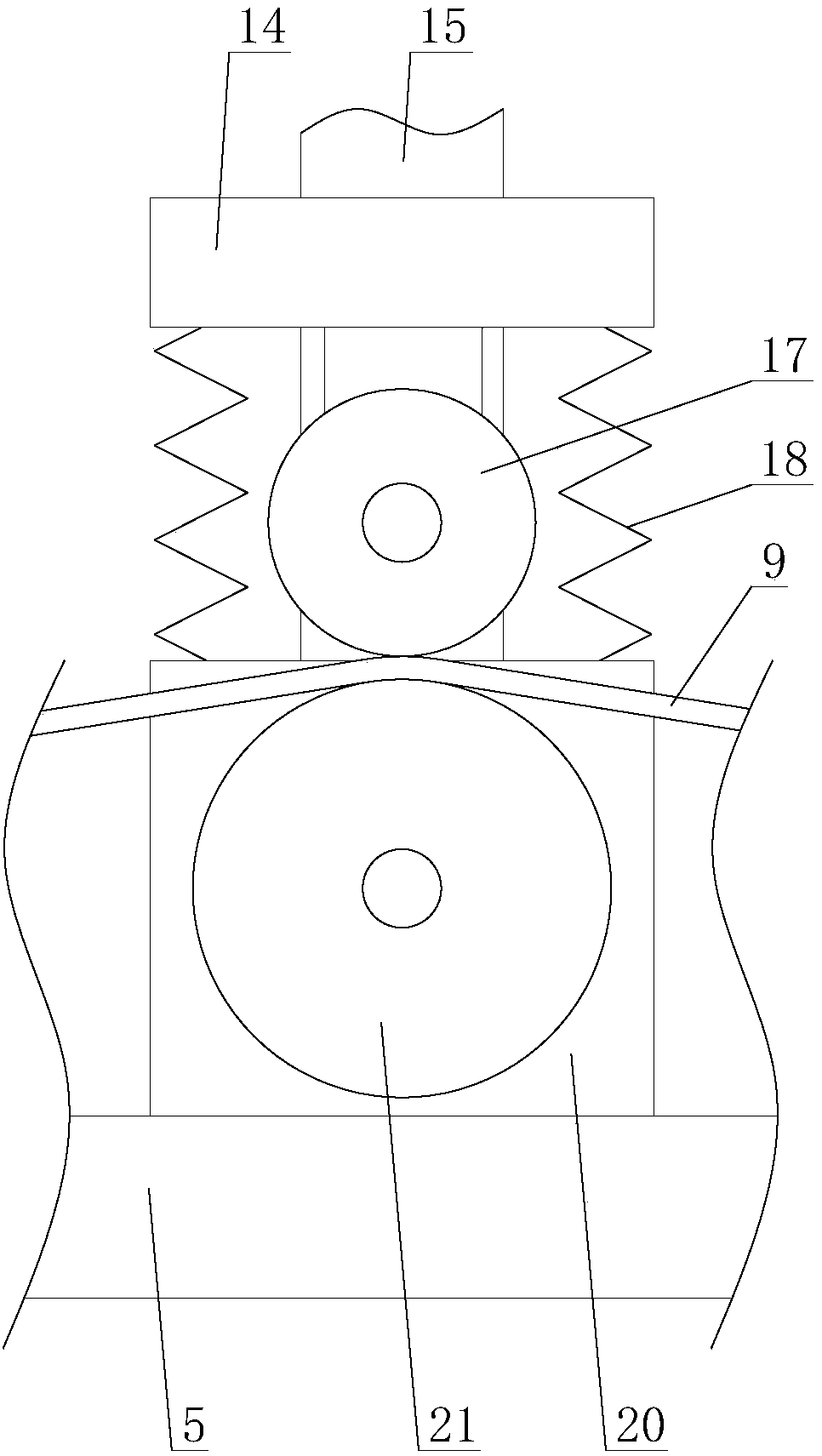

Material replacement structure of full-automatic graphene 3D printer

InactiveCN107672177ACompact structureHigh degree of automationAdditive manufacturing apparatus3D object support structuresEngineeringGraphene

The invention discloses a material replacement structure of a full-automatic graphene 3D printer. The material replacement structure comprises a stepping motor (1) and a rack (2) arranged on the rightside of the stepping motor (1). A rotary disc (10) is mounted on an output shaft of the stepping motor (1). Multiple grooves are formed in the circumferential direction of the rotary disc (10). Unreeling discs (3) are rotationally mounted in the grooves. A guide wheel (4) is rotationally mounted on the rack (2). A fixed seat (5) is arranged below the guide wheel (4) and provided with an air cylinder (6). A disc (7) is rotationally mounted on a piston rod of the air cylinder (6) through a rotary shaft. A motor (8) is fixedly mounted on the piston rod of the air cylinder (6). An output shaft ofthe motor (8) is connected with the rotary shaft. The material replacement structure has the beneficial effects that the structure is compact; the automation degree is high; the printing efficiency is improved; operation is simple; and continuous printing is achieved.

Owner:成都视必康医疗科技有限公司

A loading platform device for 3D printers used in assembly line production

ActiveCN110549623BAchieve continuous printingAchieve separationManufacturing platforms/substrates3D object support structuresComputer printingTransmission belt

Owner:湖南哈工三维科技有限公司

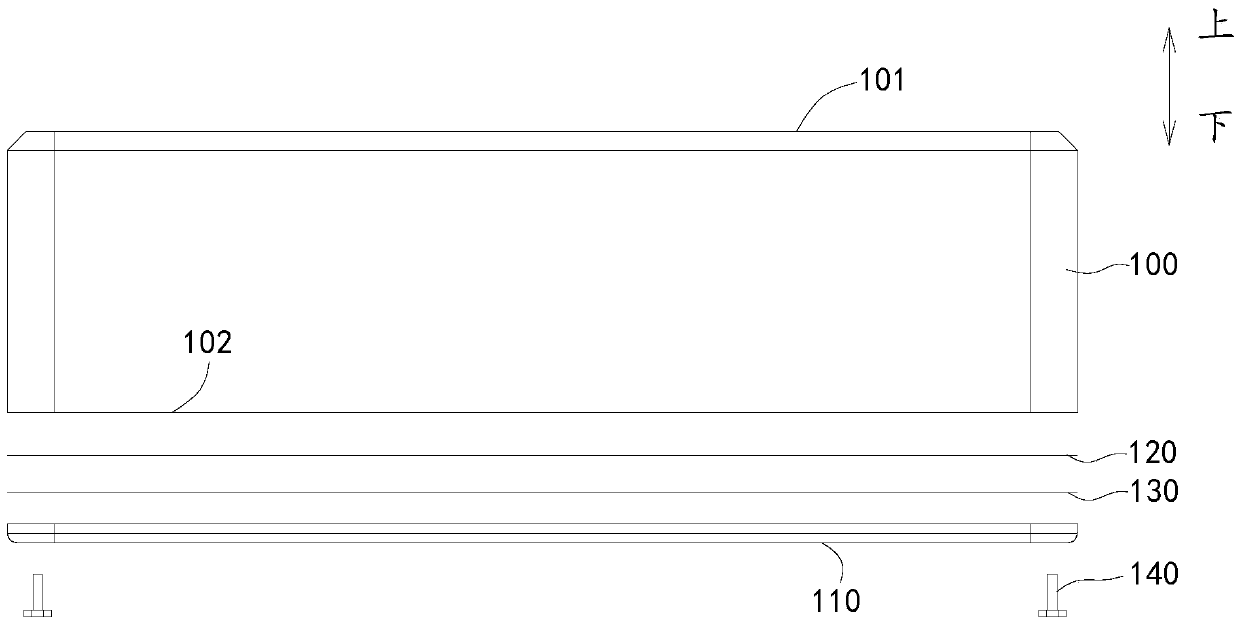

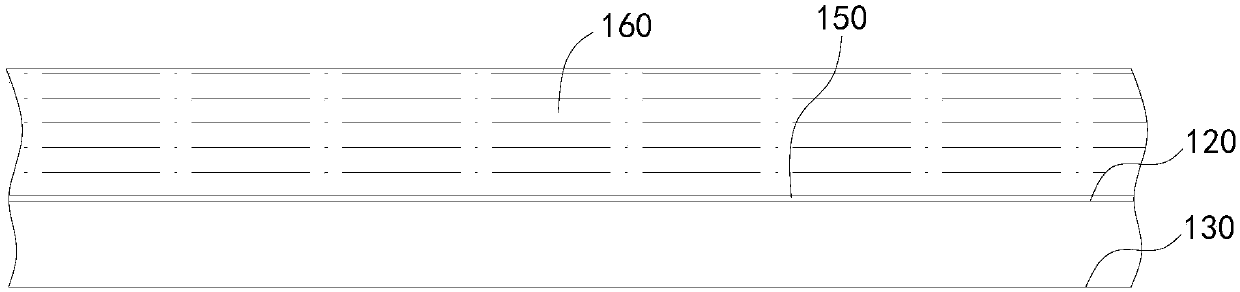

Resin pool and photocuring 3D printer

InactiveCN111196032AReduce adhesionStable printingManufacturing platforms/substrates3D object support structuresPolymer scienceComputer printing

The invention relates to a resin pool and a photocuring 3D printer. The resin pool comprises a resin pool wall, a first film and a second film, the resin pool wall is through in the vertical direction, and a first opening located in the top and a second opening located in the bottom are formed in the resin pool wall; the first film and the second film are both arranged in the second opening, the first film is close to the first opening relative to the second film, the first film has the performance that water molecules can penetrate through the first film, and the second film has the performance that the water molecules are hindered from penetrating through the second film. The resin pool solves the problem that the bonding force between a printing body and a resin pool film is too large,the printing stability can be effectively guaranteed, and the printing precision is improved.

Owner:GOLD ARRAY TECH BEIJING LLC

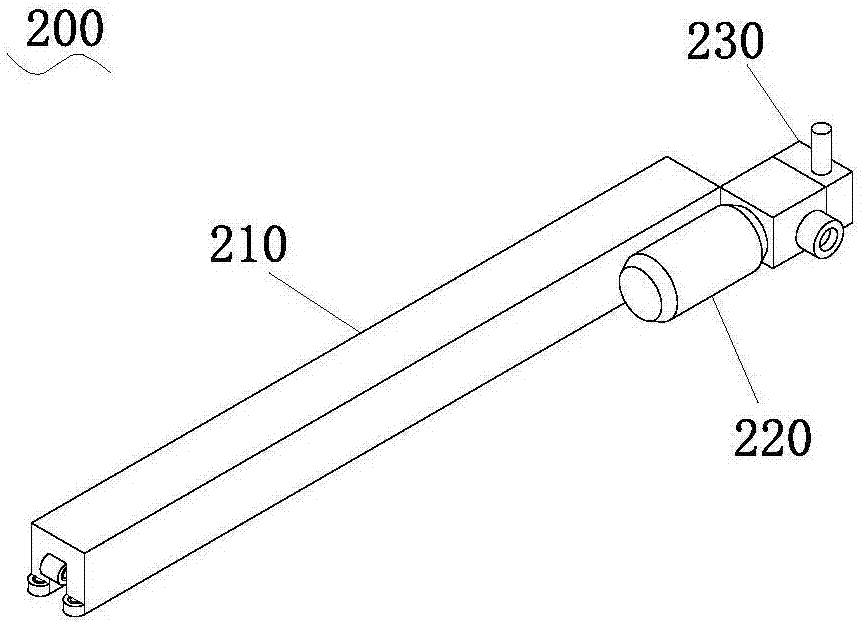

A guiding mechanism and its cutting cable 3D printing device

ActiveCN111923399BAvoid inconvenienceImprove efficiencyAdditive manufacturing apparatusAdditive manufacturing with liquids3d printManufacturing technology

The invention discloses a guiding mechanism and its cutting cable 3D printing device. The cutting cable 3D printing device includes a printing module, which uses melted plastic as a raw material to print out an inner tube, and at the same time fills the inner cavity of the inner tube with a fat-like explosive; The mechanism makes the printed inner tube continuously extend in the axial direction by continuously moving down to obtain a longer inner tube, and at the same time ensures that the printing end surface of the inner tube and the printing module does not move to ensure printing accuracy. The winding mechanism is used for winding the printed inner tube, so that the processing of the longer inner tube can be realized. The present invention adopts 3D printing inner tube, injects fat-like explosive into the inner tube at the same time, then manufactures the outer tube separately, finally puts the inner tube into the outer tube, and stretches the outer tube so that the outer tube can clamp the inner tube . Its efficiency is much higher than that of traditional cutting wires, and the cross-section of cutting wires obtained is relatively standard, so the performance of cutting wires is also better, which is a revolutionary breakthrough in the manufacturing technology of cutting wires.

Owner:CHONGQING VOCATIONAL INST OF ENG

A continuous 3D printing system

ActiveCN109228315BAvoid mechanical strippingAvoid mechanical propertiesAdditive manufacturing apparatus3D object support structuresPhotocatalytic degradationPhoto catalysis

Owner:TAIZHOU POLYTECHNIC COLLEGE

A temperature-adjustable food 3D printer

InactiveCN107223748BAvoid bloomingImprove liquidityAdditive manufacturing apparatusCocoaComputer printingElectric machinery

The invention belongs to a technical field related to food printing, and discloses a temperature-adjustable 3D food printer. The printer comprises a support frame, a storage device arranged on the support frame, a continuous feeding mechanism, and a motion mechanism. The storage device and the continuous feeding mechanism are arranged at an interval, and food materials are continuously added into the storage device. The motion mechanism is connected with the continuous feeding mechanism, wherein motors rotate so as to drive the continuous feeding mechanism to move. The 3D food printer also comprises a temperature adjusting device, wherein the temperature adjusting device separately communicates with the storage device and the continuous feeding mechanism. The temperature adjusting device conducts an automatic temperature adjustment on fluid food carried by the storage device. After the temperature adjustment, the temperature adjusting device transfers the fluid food to the continuous feeding mechanism. The 3D food printer realizes the automatic temperature adjustment on the fluid food by setting the temperature adjusting device. The storage device cooperates with the continuous feeding mechanism so as to realize continuous printing and improve food print efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

A cutting cable 3D printing process and its device

ActiveCN111923400BAvoid inconvenienceImprove efficiencyAdditive manufacturing apparatusAdditive manufacturing with liquidsManufacturing technologyMachining

The invention discloses a cutting cable 3D printing process and its device. The cutting cable 3D printing device includes a printing module, which uses melted plastic as a raw material to print out an inner tube, and at the same time fills the inner cavity of the inner tube with a fat-like explosive; a guiding mechanism , by continuously moving down, the printed inner tube is continuously extended in the axial direction to obtain a longer inner tube, and at the same time, the printing end surface of the inner tube and the printing module is kept still to ensure printing accuracy. The winding mechanism is used for winding the printed inner tube, so that the processing of the longer inner tube can be realized. The present invention adopts 3D printing inner tube, injects fat-like explosive into the inner tube at the same time, then manufactures the outer tube separately, finally puts the inner tube into the outer tube, and stretches the outer tube so that the outer tube can clamp the inner tube . Its efficiency is much higher than that of traditional cutting wires, and the cross-section of cutting wires obtained is relatively standard, so the performance of cutting wires is also better, which is a revolutionary breakthrough in the manufacturing technology of cutting wires.

Owner:CHONGQING VOCATIONAL INST OF ENG

An efficient 3D printer with platform cleaning function based on Internet of Things

ActiveCN108262959BImprove cleanlinessImprove printing accuracyManufacturing driving meansCleaning using toolsComputer printingThe Internet

The invention relates to an efficient 3D printer with platform cleaning function based on the Internet of Things. It includes a base, a bracket and a printing module. It also includes a switching mechanism, a cleaning mechanism and a central control mechanism. The switching mechanism includes a moving component, a power component, and a transmission belt. , support rod and two switching components. The cleaning mechanism includes a driving component, a limit block, a casing, a cylinder, a third motor, a first cleaning brush and a second cleaning brush. The IoT-based platform cleaning function In an efficient 3D printer, through the switching mechanism, the two platforms of the 3D printer can be switched, so that one platform is in the working state while the other platform is in the ready state, thus realizing the continuous printing of the 3D printer, thus improving the efficiency of the 3D printer. The printing efficiency is improved. Through the cleaning mechanism, one platform can be used to clean the other platform at the same time, thereby improving the cleanliness of the platform and thus improving the printing accuracy of the 3D printer.

Owner:SHAANXI HENGTONG INTELLIGENT MACHINE

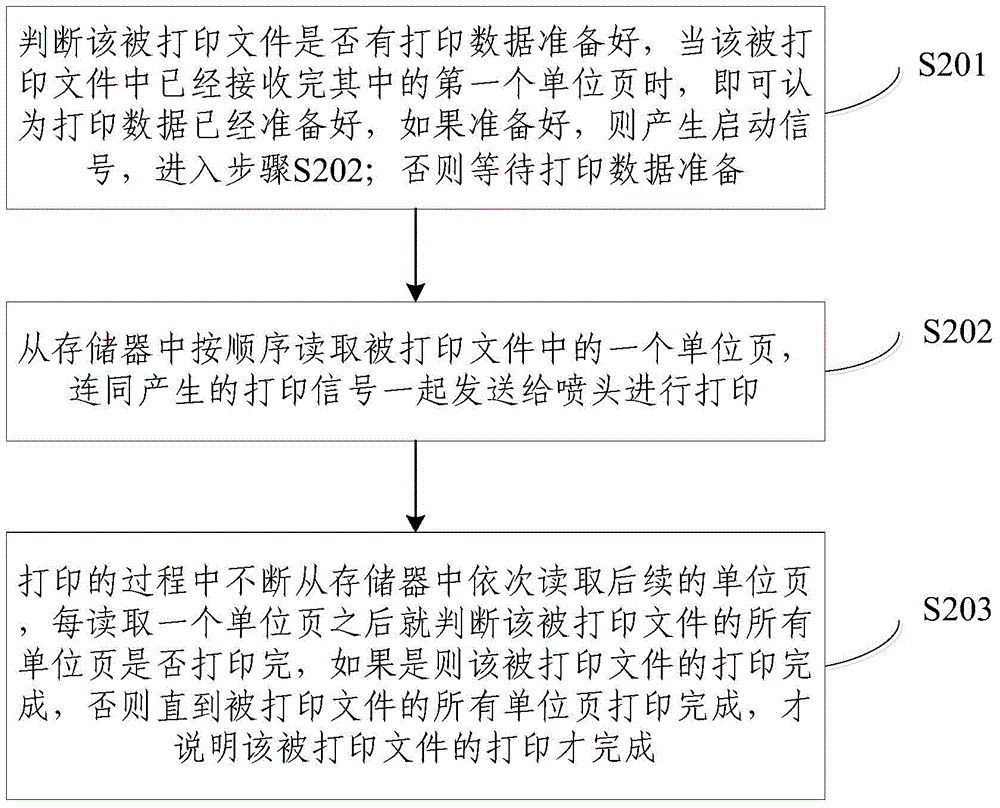

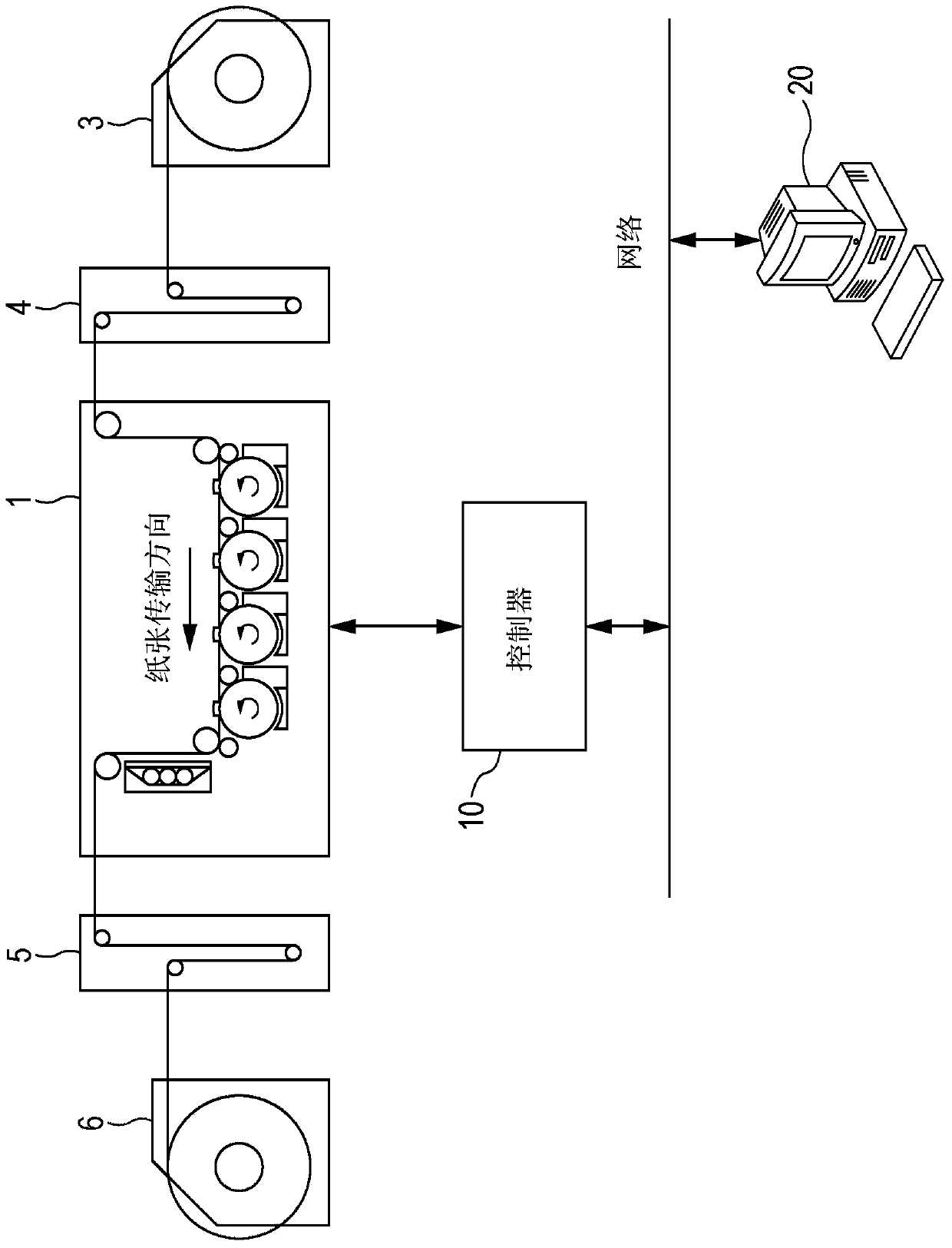

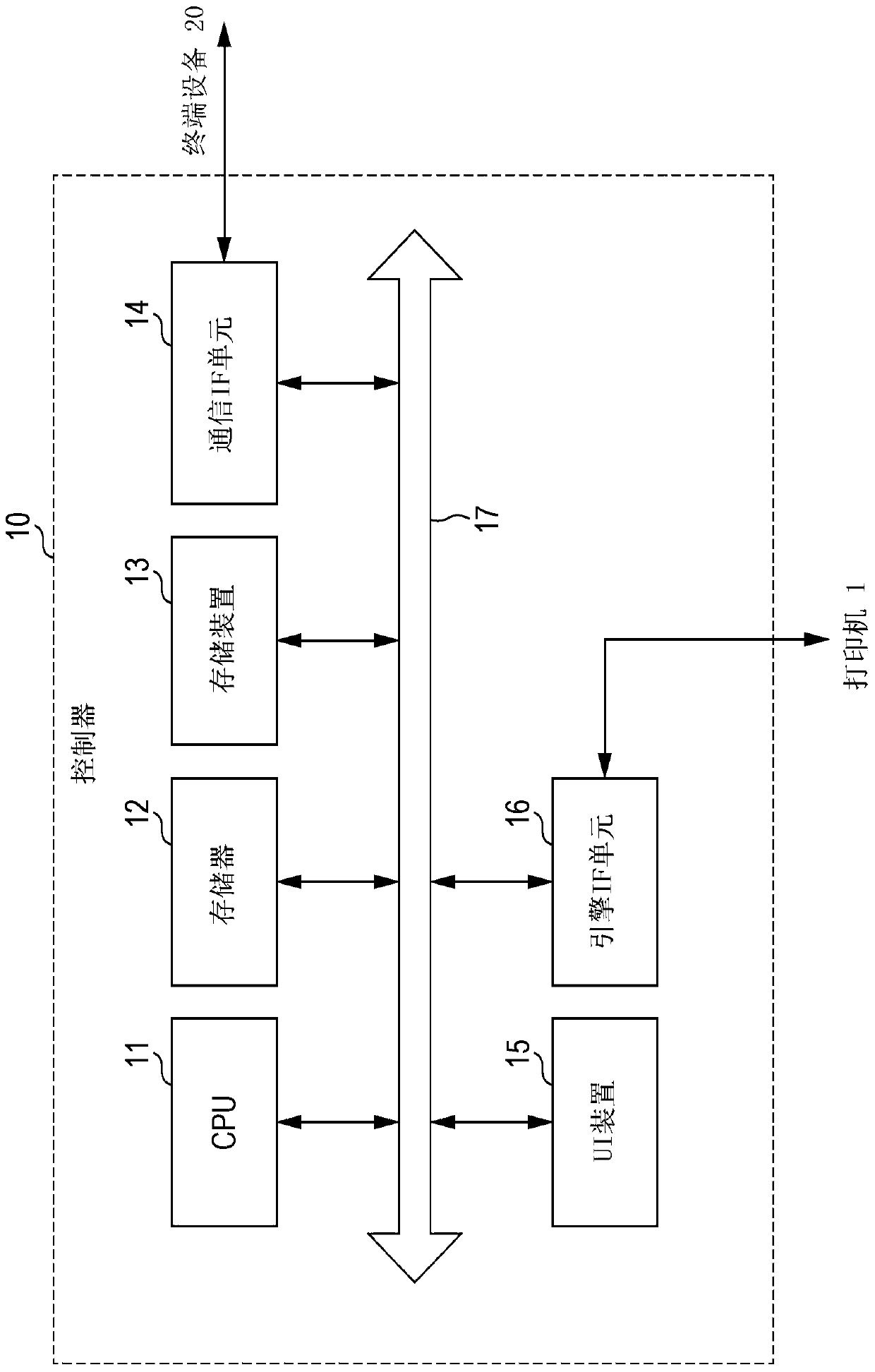

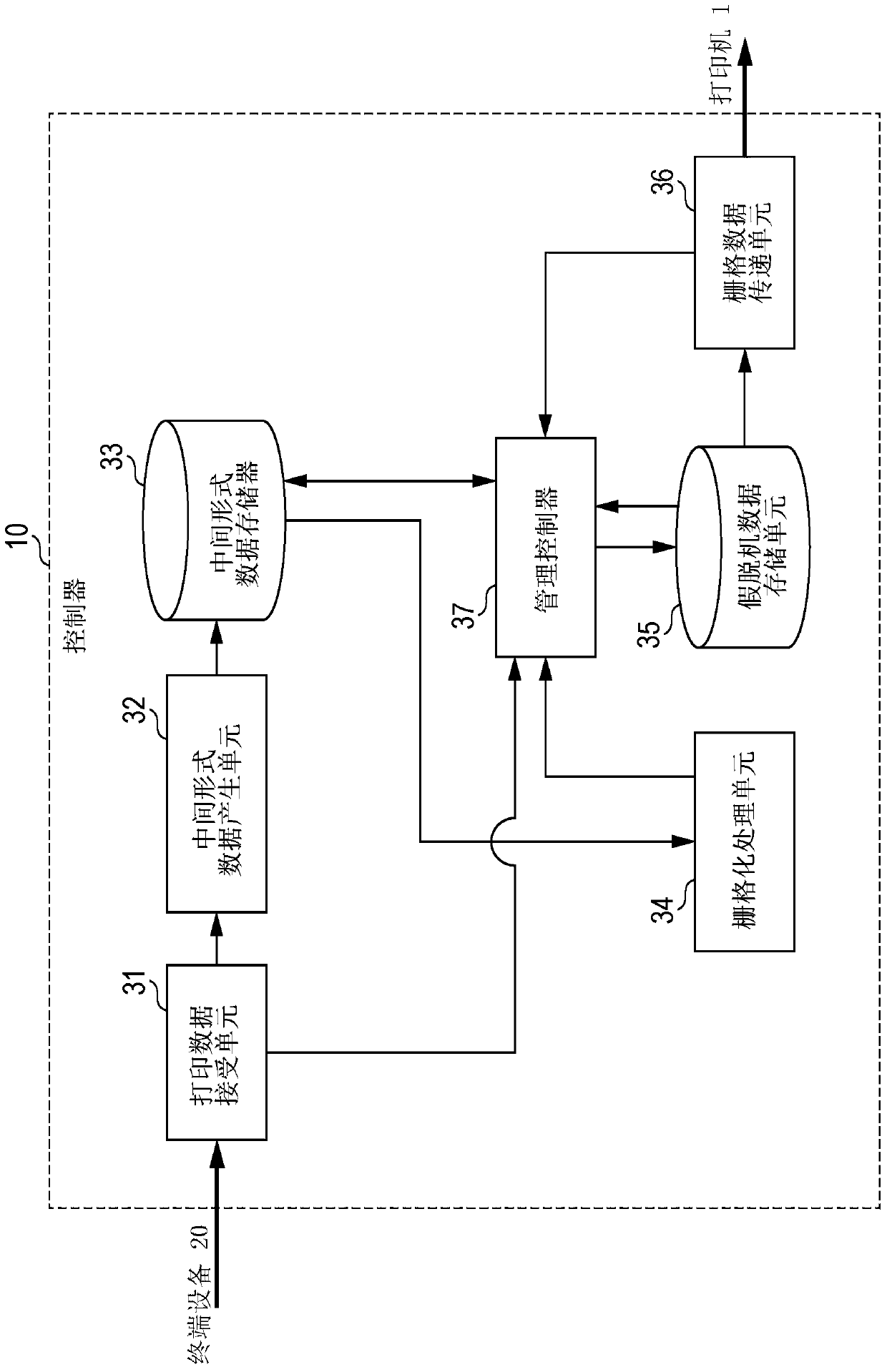

Print control device, print control method, and image forming system

ActiveCN105975216BAchieve continuous printingIntermittent printing does not occurElectrographic process apparatusDigital output to print unitsComputer engineeringGenerating unit

A print control device, a print control method, and an image forming system. A printing control device includes a generating unit, a storage unit, a transfer unit, a memory and a controller. The generation unit generates image data by performing rendering processing according to the print instruction. The storage unit stores the data. The transfer unit reads image data stored in the storage unit and transfers to a printer that performs printing on continuous paper. The memory associates and stores the processing time and the printing instruction for each page in the printing instruction. The processing time is the sum of the time from when the generation unit starts rendering processing to when the image data is stored in the storage unit and the time from when the transfer unit reads the image data from the storage unit to when the read data is transferred to the printer. In response to accepting an instruction to reprint the print order, the controller controls image data generated by the generation unit to be stored in the storage unit or sent to the transfer unit based on the processing time of each page stored in the memory in association with the print order.

Owner:FUJIFILM BUSINESS INNOVATION CORP

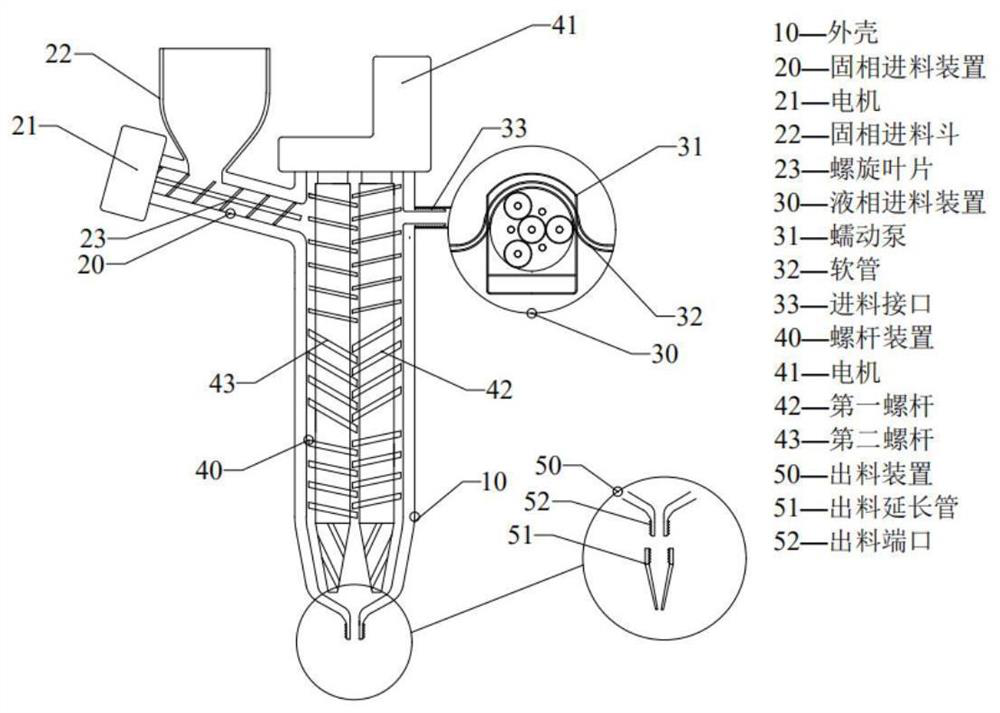

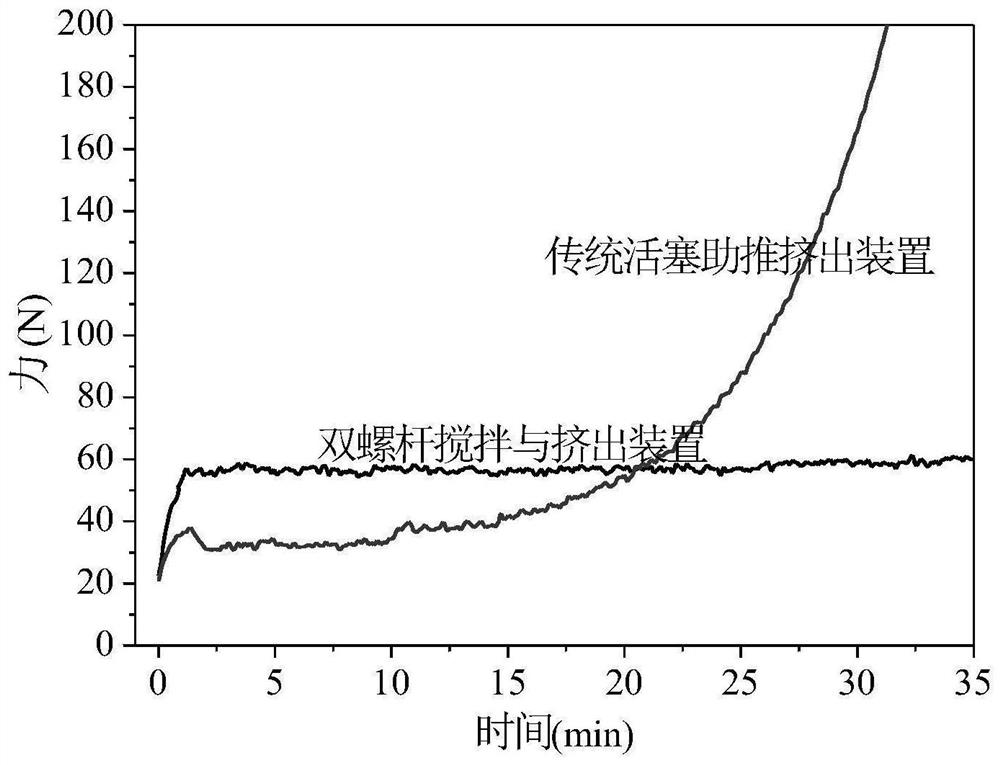

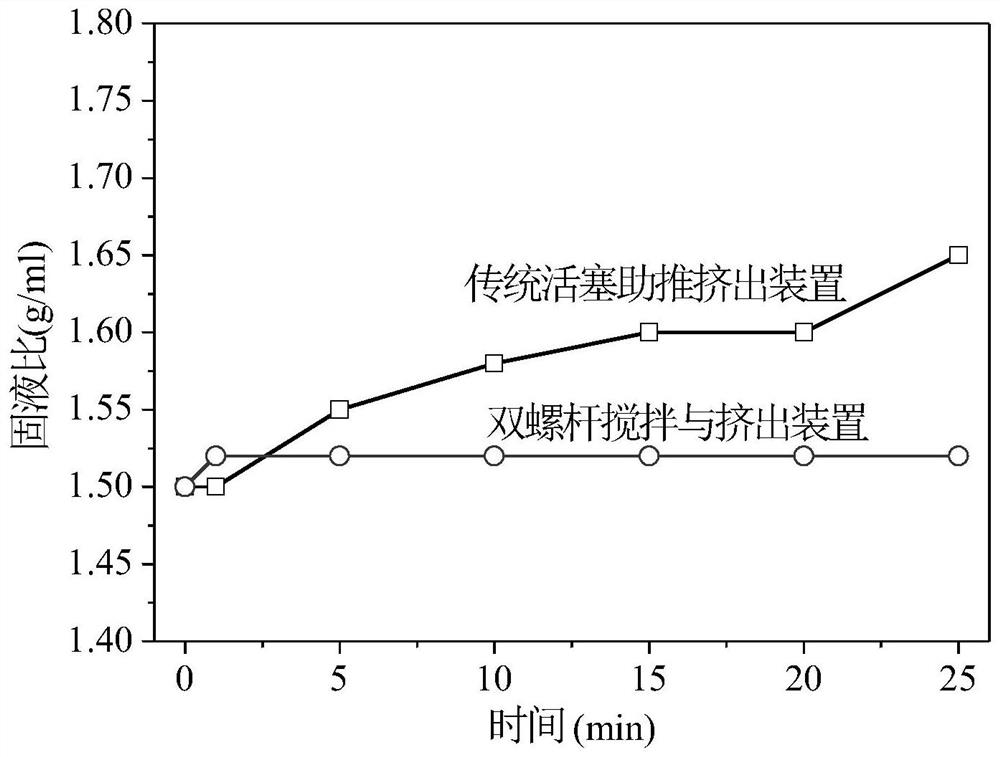

Double-screw stirring and extruding device for bone cement 3D printing

InactiveCN112976222AImprove liquidityImprove compactnessAdditive manufacturing apparatusCeramic shaping apparatusPeristaltic pumpSpiral blade

The invention discloses a double-screw stirring and extruding device for bone cement 3D printing, and belongs to the field of 3D printing. The double-screw stirring and extruding device mainly comprises a shell, a solid-phase feeding device, a liquid-phase feeding device, a screw device and a discharging device; the solid-phase feeding device comprises a motor, a solid-phase feeding hopper and a spiral blade; the liquid-phase feeding device comprises a peristaltic pump, a hose and a feeding connector; the screw device comprises a motor, a first screw and a second screw, wherein the first screw and the second screw are opposite in rotation direction; and the discharging device comprises a discharging extension pipe and a discharging port. The double-screw design is adopted, solid-phase materials and liquid-phase materials can be stirred and mixed evenly, slurry can be effectively extruded, and the phenomena of phase separation, pressure filtering, discharging port blockage and the like of a traditional extruding device are avoided; and the problem that the stirring efficiency of a single screw on part of materials is low is solved, and the 3D printing discharging stability, printing efficiency and precision can be improved.

Owner:JINLING INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com