A continuous 3D printing system

A 3D printing and photosensitive resin technology, which is applied in 3D object support structures, manufacturing tools, additive manufacturing, etc., can solve problems such as precision constraints, long printing cycles, and long leveling time of photosensitive resins, so that it is not easy to break and deform, and print Process controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

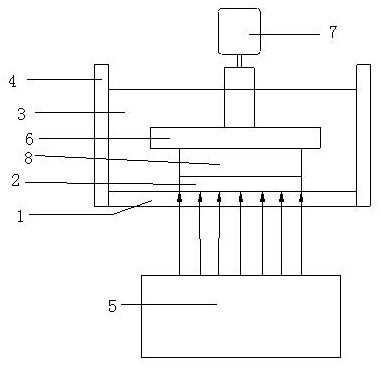

[0029] like figure 1 As shown, the continuous 3D printing system of this embodiment includes a light-transmitting window (1), an uncured layer (2), a photosensitive resin (3), a trough (4), an optical device (5), and an object stage (6 ), motor (7) and cured product (8), described light-transmitting window (1) is positioned at the bottom of trough (4); described photosensitive resin (3) is located at the inside of trough (4);

[0030] The photosensitive resin (3) contains titanium dioxide nanoparticles and a component that can be photocatalytically degraded into a polymerization inhibitor;

[0031] The photosensitive resin (3) contains nano-titanium dioxide particles with a particle size of 1 nm; the crystal form of the nano-titanium dioxide is an anatase structure.

[0032] In the photosensitive resin (3), the component that can be photocatalytically degraded into a polymerization inhibitor is quinhydrone;

[0033] The formation process of the uncured layer is as follows: t...

Embodiment 2

[0038] like figure 1 As shown, the continuous 3D printing system of this embodiment includes a light-transmitting window (1), an uncured layer (2), a photosensitive resin (3), a trough (4), an optical device (5), and an object stage (6 ), motor (7) and cured product (8), described light-transmitting window (1) is positioned at the bottom of trough (4); described photosensitive resin (3) is located at the inside of trough (4);

[0039] The photosensitive resin (3) contains titanium dioxide nanoparticles and a component that can be photocatalytically degraded into a polymerization inhibitor;

[0040] The photosensitive resin (3) contains nano-titanium dioxide particles with a particle size of 300 nm; the crystal form of the nano-titanium dioxide is an anatase structure.

[0041] In the photosensitive resin (3), the component that can be photocatalytically degraded into a polymerization inhibitor is bis(2-diphenylphosphophenyl) ether;

[0042] The formation process of the uncured...

Embodiment 3

[0047] like figure 1 As shown, the continuous 3D printing system of this embodiment includes a light-transmitting window (1), an uncured layer (2), a photosensitive resin (3), a trough (4), an optical device (5), and an object stage (6 ), motor (7) and cured product (8), described light-transmitting window (1) is positioned at the bottom of trough (4); described photosensitive resin (3) is located at the inside of trough (4);

[0048] The photosensitive resin (3) contains titanium dioxide nanoparticles and a component that can be photocatalytically degraded into a polymerization inhibitor;

[0049] The photosensitive resin (3) contains nano-titanium dioxide particles with a particle size of 30 nm; the crystal form of the nano-titanium dioxide is an anatase structure.

[0050] The components that can be photocatalytically degraded into polymerization inhibitors in the photosensitive resin (3) are quinhydrone and hydrogen peroxide, and the molar ratio is 4:1;

[0051] The form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com