A kind of black phosphorus quantum dot/attapulgite nanocomposite material and its preparation method and application

A nanocomposite material and composite material technology are applied in the field of black phosphorus quantum dots/attapulgite nanocomposite materials and their preparation, which can solve the problems of limiting the functional application prospect of black phosphorus quantum dots and the harsh preparation process, and avoid mechanical peeling. , the effect of uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

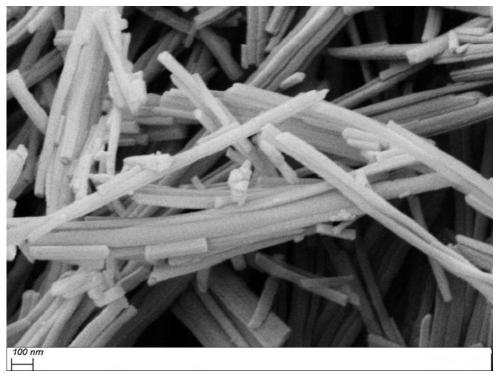

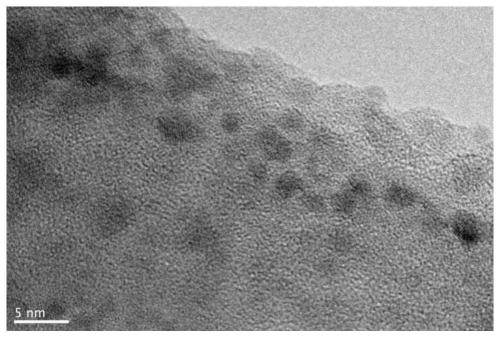

[0015] Disperse 0.35g of black phosphorus powder, 1.0g of attapulgite and 0.2g of NaOH in 100ml of n-methyl-2-pyrrolidone, and vigorously stir at 120°C for 10 hours under the protection of nitrogen. Take the upper suspension and dry it in vacuum to obtain the black phosphorus quantum dot / attapulgite nanocomposite material. The obtained product is observed with a scanning electron microscope and a transmission electron microscope. The SEM and TEM images are as follows: figure 1 with figure 2 Shown: the attapulgite rods present a nanorod-like structure, and the black phosphorus quantum dots are uniform in size and are evenly loaded on the attapulgite rods.

[0016] The black phosphorus quantum dot / attapulgite nanocomposite material in Example 1 is used for photocatalytic denitrification immediately after the preparation is completed. The gas ratio is: 0.1% (volume percentage relative to the total gas flow, the same below) NH 3 , 0.1% NO and 3% O 2 , N 2 As the balance gas, ...

Embodiment 2

[0030] Disperse 0.32g of black phosphorus powder, 0.8g of attapulgite and 0.3g of NaOH in 100ml of n-methyl-2-pyrrolidone and stir vigorously at 140°C for 8 hours under the protection of argon. After the reaction, centrifuge at 7000rpm for 2h , take the upper suspension and dry it in vacuum to obtain the black phosphorus quantum dot / attapulgite nanocomposite material, and the subsequent detection is as in Example 1.

Embodiment 3

[0032] Disperse 0.28g of black phosphorus powder, 1.0g of attapulgite and 0.3g of NaOH in 100ml of n-methyl-2-pyrrolidone, and vigorously stir at 160°C for 6 hours under nitrogen protection. After the reaction, centrifuge at 7000rpm for 2h, Take the upper suspension and dry it in vacuum to obtain the black phosphorus quantum dot / attapulgite nanocomposite material, and the subsequent detection is as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com