3D printer capable of realizing continuous printing

A technology of 3D printers and printing components, applied in the direction of additive processing, etc., can solve the problems of low efficiency, difficult to remove fixed materials, inconvenience, etc., and achieve the effect of continuous printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

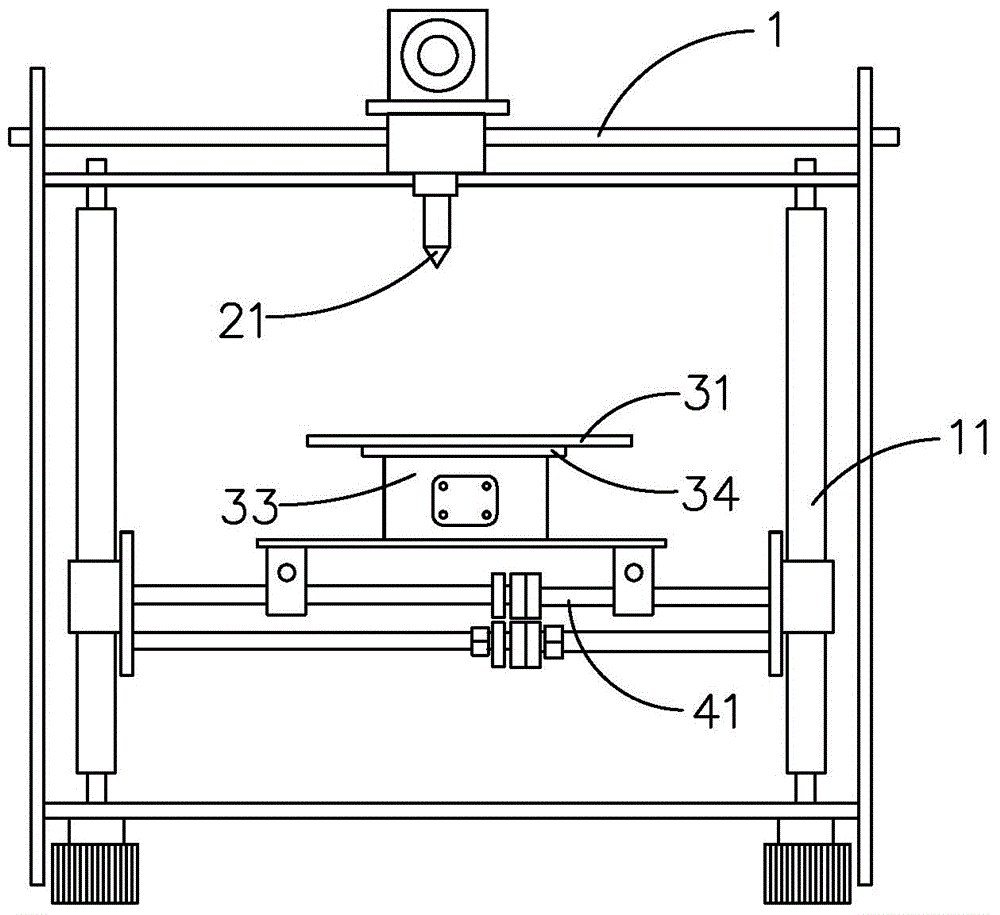

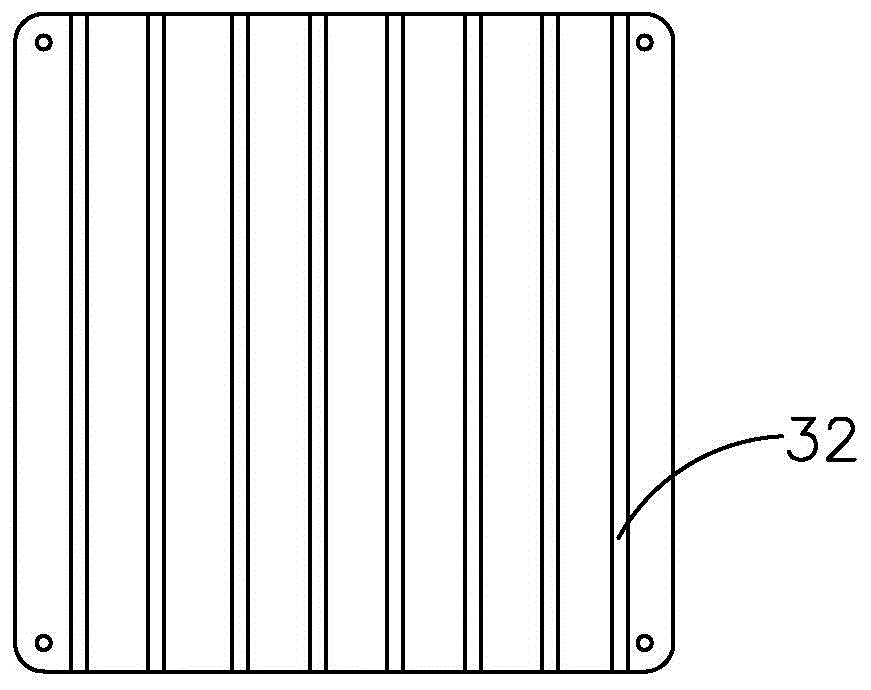

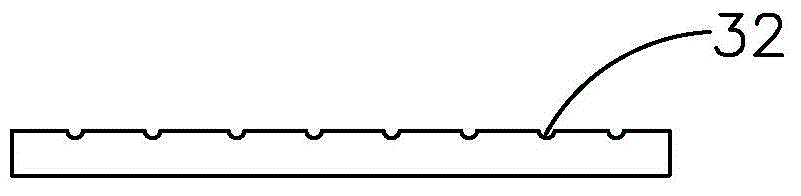

[0018] like Figure 1 to Figure 4 As shown, the 3D printer provided by the present invention includes a frame 1, a nozzle assembly, a printing assembly and an adjustment assembly. The frame 1 is mainly used to install various components of the 3D printer to corresponding positions, and these components include but are not limited to: nozzles Components, printing components and adjustment components; the spray head assembly is installed on the top of the frame 1 and can move in the horizontal and vertical directions, including the wire feeding rollers, wire guide tubes and nozzles 21 that have a pressing function for the fuse; the printing The assembly is located under the nozzle assembly to fix and support the printed parts; the adjustment assembly is installed on the vertical bar 11 of the frame 1 and can move along the axis of the vertical bar 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com