Double-screw stirring and extruding device for bone cement 3D printing

A 3D printing and extrusion device technology, applied in ceramic molding machines, manufacturing tools, additive processing, etc., can solve problems such as low mixing efficiency and difficult molding, and achieve the effects of improving efficiency, improving compactness, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

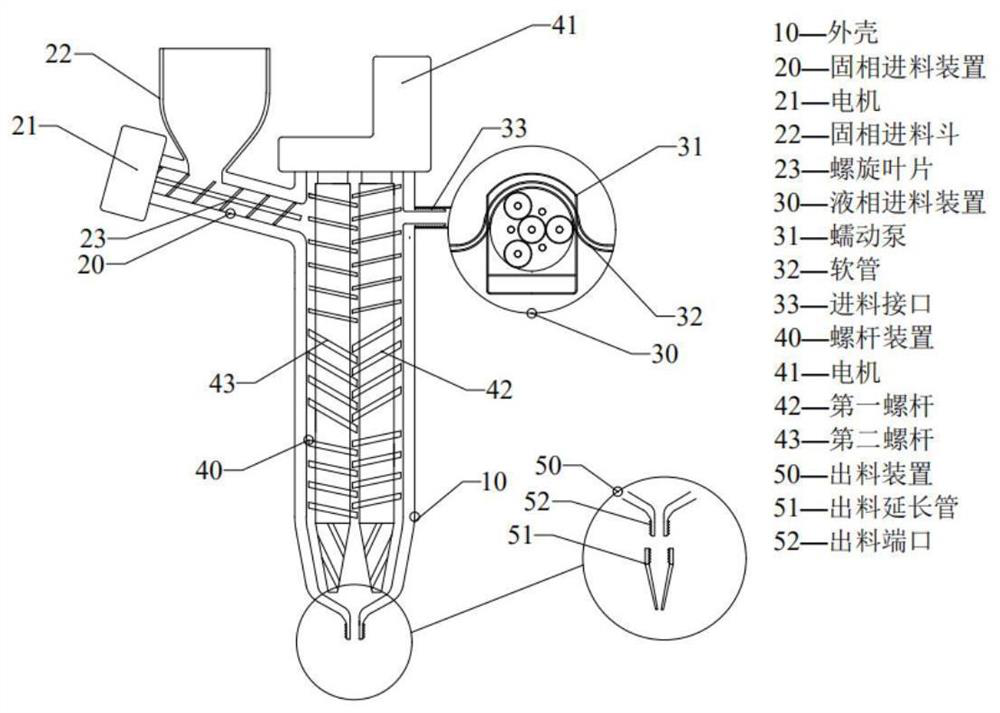

[0041] A twin-screw stirring and extruding device for bone cement 3D printing, including a housing 10, a solid phase feeding device 20, a liquid phase feeding device 30, a screw device 40 and a discharging device 50; wherein, the solid phase feeding device 20 Comprising motor 21, solid phase feed hopper 22 and screw blade 23; Liquid phase feed device 30 comprises peristaltic pump 31, hose 32 and feeding interface 33; Screw device 40 comprises motor 41, first screw rod 42 and second screw rod 43; the discharge device 50 includes a discharge extension pipe 51 and a discharge port 52;

[0042] The housing 10 is a hollow structure with a columnar structure in the middle, a columnar structure extending obliquely upward on the left side of the top, and an inverted convex structure at the bottom; There is an opening connected to the solid phase feeding device 20 at the end of the columnar structure, an opening connected to the solid phase feeding hopper 22 is left in the middle and u...

Embodiment 2

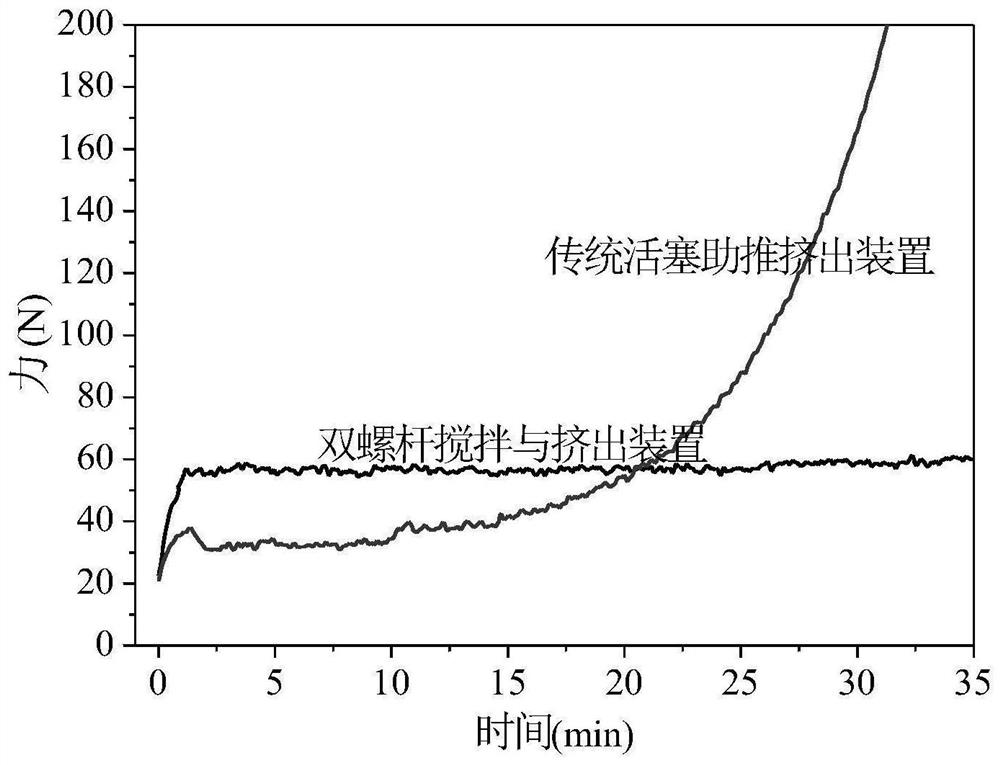

[0053] First, a traditional piston-assisted extrusion device is used, the size of the discharge port is 2mm, the phosphate bone cement is used as the printing material, the ratio of the solid phase and the liquid phase is 1.5g / ml, and the solid and liquid phases are stirred evenly before being placed. Into the barrel, the discharge speed is adjusted to 40g / min. Then adopt a kind of bone cement 3D printing of the present invention to use twin-screw stirring and extruding device (such as figure 1 As shown), the same phosphate bone cement was used as the printing material, the solid phase feeding speed was adjusted to 80g / min, the liquid phase feeding speed was adjusted to 13ml / min, and the ratio of solid phase and liquid phase was 1.5g / ml. The diameter of the discharge port is 3 mm, the diameter of the discharge extension pipe and the opening diameter of the discharge extension pipe are both 2 mm, and the discharge speed is about 40 g / min. The piston propulsion force of its tra...

Embodiment 3

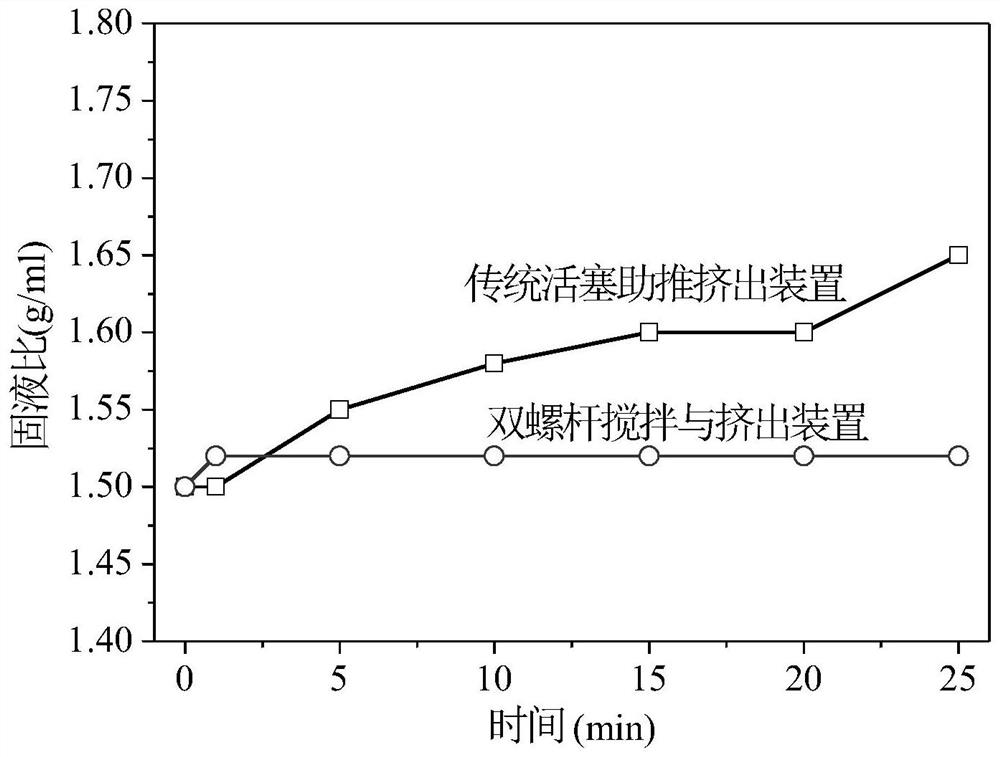

[0055] Firstly, a traditional piston-assisted extrusion device was adopted, the size of the discharge port was 2mm, and the phosphate bone cement was selected as the printing material. The ratio of solid phase and liquid phase (solid-liquid ratio) was 1.5g / ml. After the phase is stirred evenly, it is put into the barrel, and the discharge speed is adjusted to 40g / min. Then use a twin-screw stirring and extrusion device for bone cement 3D printing of the present invention, use the same bone cement as the printing material, adjust the solid phase feed rate to 80g / min, and the liquid phase feed rate to 13ml / min, The ratio of solid phase to liquid phase (solid-liquid ratio) is 1.5g / ml, the diameter of the discharge port is 3mm, the diameter of the discharge extension tube is 2mm, and the discharge speed is about 40g / min. Test the solid-to-liquid ratio (g / ml) of the bone cement paste at the printing outlet at 0min, 1min, 5min, 10min, 15min, 20min, and 25min respectively, and the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com