Photocuring 3D printer and printing method

A 3D printer and light curing technology, applied in the field of 3D printing, can solve the problems of low printing efficiency and long printing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

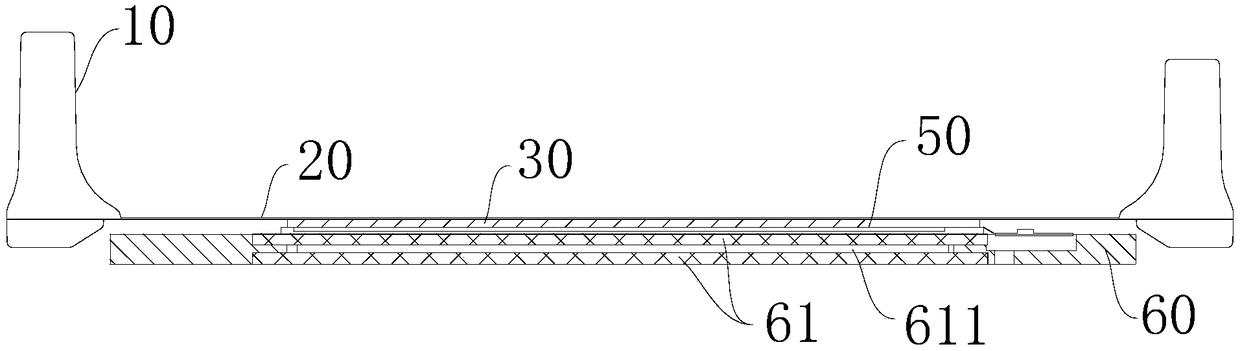

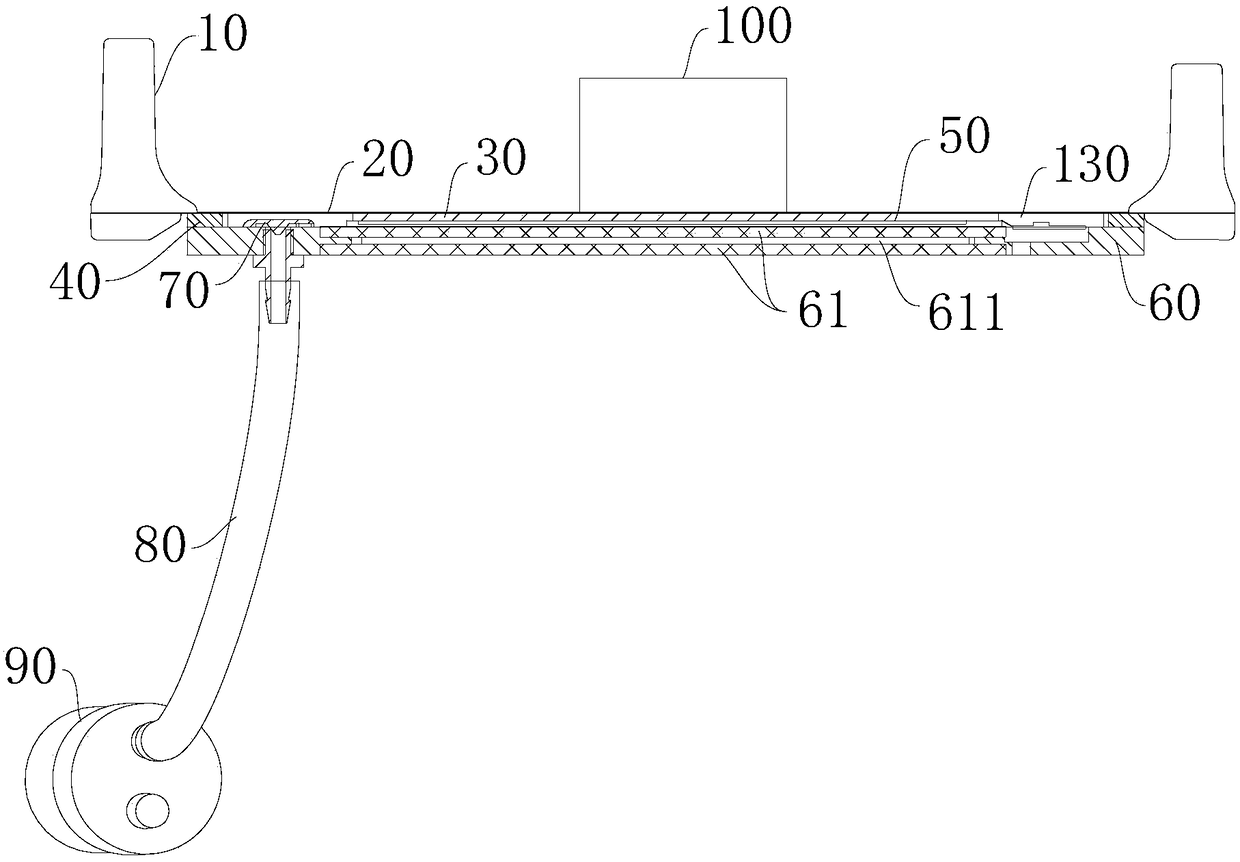

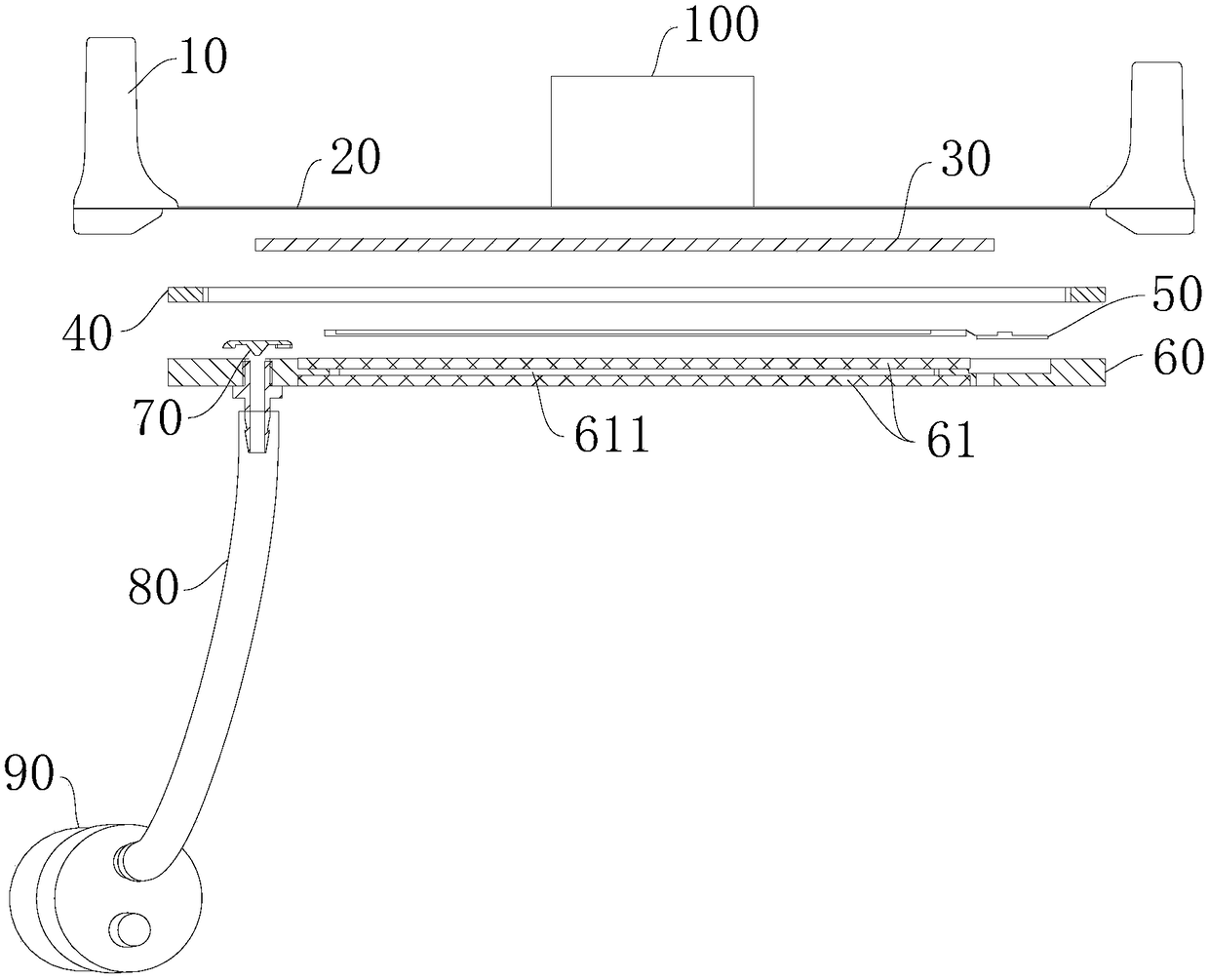

[0051] Specific embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not intended to limit the present disclosure.

[0052] The inventor found in the research that when each layer is printed, there is adhesion between the cured resin and the upper layer of printing body and resin pool film. In order to maintain the continuation of printing, that is, there is a need for Replenish the liquid resin, and the cured resin should be separated from the resin pool membrane as well as possible. If the separation force is too large, it may cause the current layer of prints to peel off from the previous layer of prints, resulting in printing failure or defects on the surface of the printed model. ; If the separation force is too small, the printing process can be carried out sequential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com