Continuous printing device and method for outer surfaces of cylinders

A technology of the outer surface and printing device, which is applied in the direction of power transmission device, printing, typewriter, etc., can solve the problems of poor printing quality, non-printing, and gaps in pattern connection, etc., so as to reduce non-printing time, improve printing efficiency, and improve The effect of printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

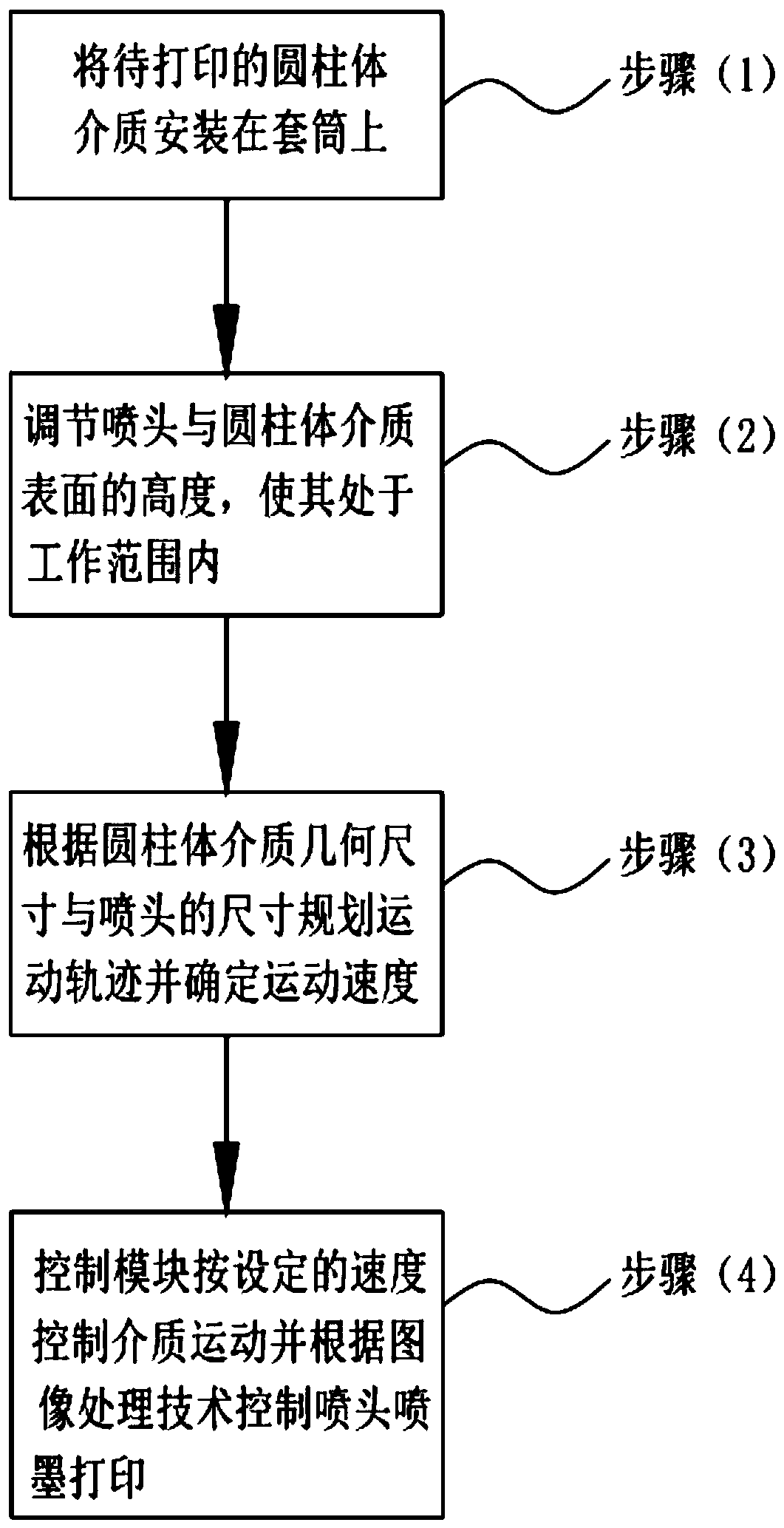

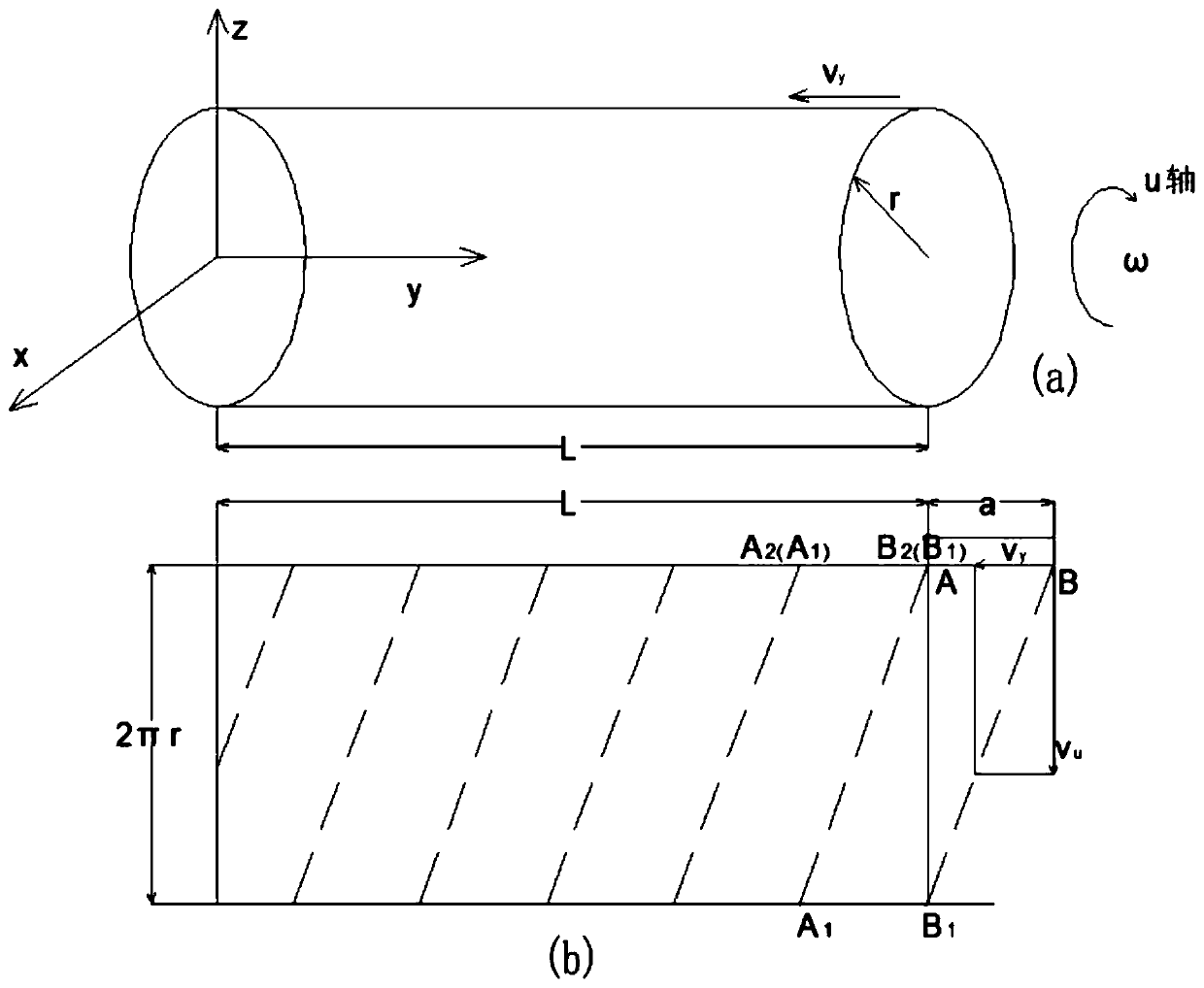

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

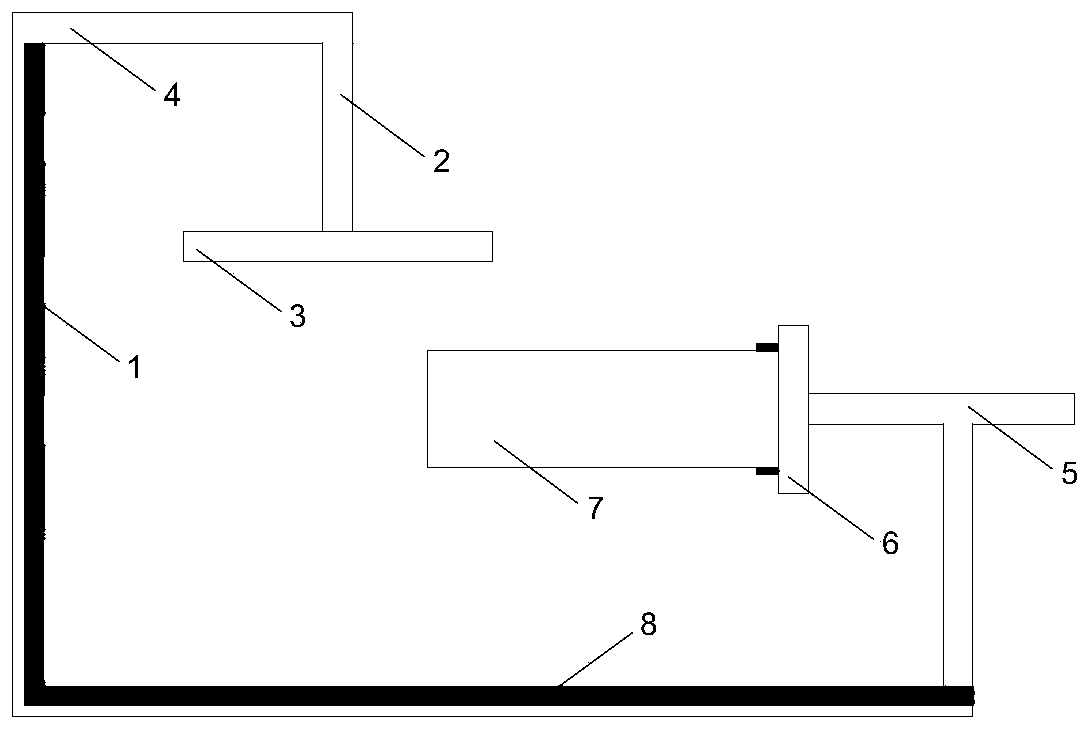

[0038] A continuous printing device on the outer surface of a cylinder in this embodiment includes a cylinder medium installation module, a nozzle adjustment module, a nozzle control module, a main control module, and a motion control module 8;

[0039] The cylinder medium installation module is arranged at one end of the motion control module 8, the nozzle adjustment module is arranged at the other end of the motion control module 8, and the nozzle control module is arranged on the nozzle adjustment module;

[0040] The cylinder medium installation module is used to install the cylinder medium 7 to be printed, the axis of the cylinder and the printing plane of the nozzle, and the sleeve rotation of the cylinder installation module drives the cylinder medium 7 to rotate around the axis during the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com