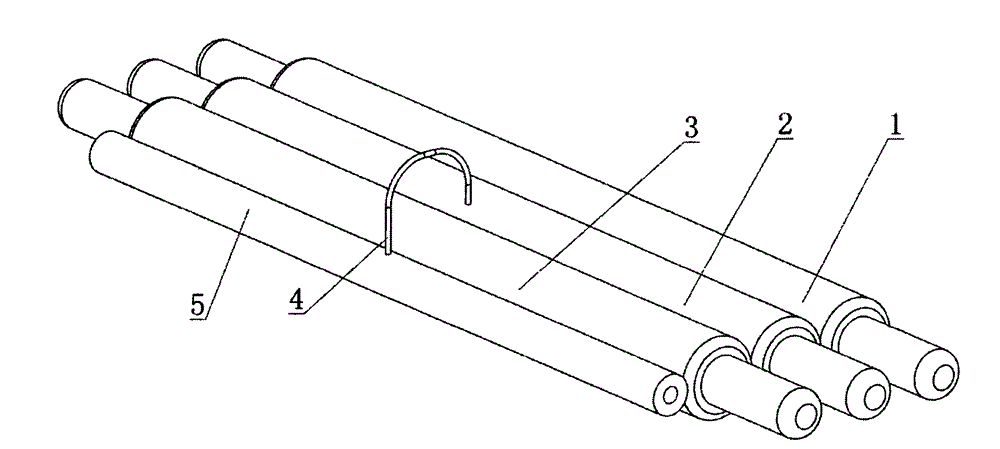

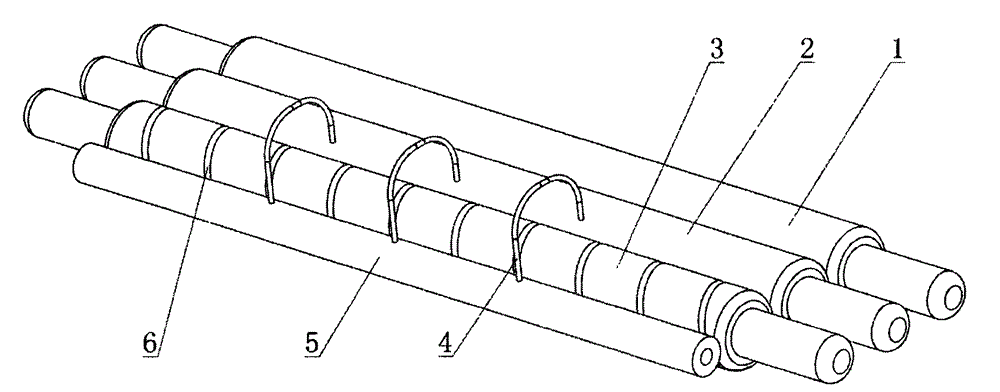

Gluing unit of CTP (Computer To Plate)

A technology of plate making machine and cot, applied in the direction of coating, device for coating liquid on the surface, etc., can solve the problems of low work efficiency, dirty layout, etc. The effect of printing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The invention will be described in further detail below in conjunction with the accompanying drawings and examples, but the following examples are only examples of the present invention, and do not represent the limited scope of rights of the present invention. The scope of protection of the present invention is defined in the claims prevail.

[0014] according to figure 1 and figure 2 The present invention is described in detail. A gluing unit of a CTP plate-making machine according to the present invention includes a rubber pressing roller 1 , a gluing roller 2 , a gluing roller 3 , and a gluing tube 5 installed on a frame (not shown in the figure). Three glue outlet holes (not shown in the figure) are evenly distributed on the upper glue pipe 5, and a glue outlet pipe matched with the glue outlet hole is provided on the glue outlet hole. The roll surfaces of the upper rubber roller are respectively tangent to the roller surfaces of the pressure rubber roller and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com