Continuous type platform printing device

A printing device and platform technology, applied in printing devices, printing, typewriters, etc., can solve problems such as uneven fabrics and irregular patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

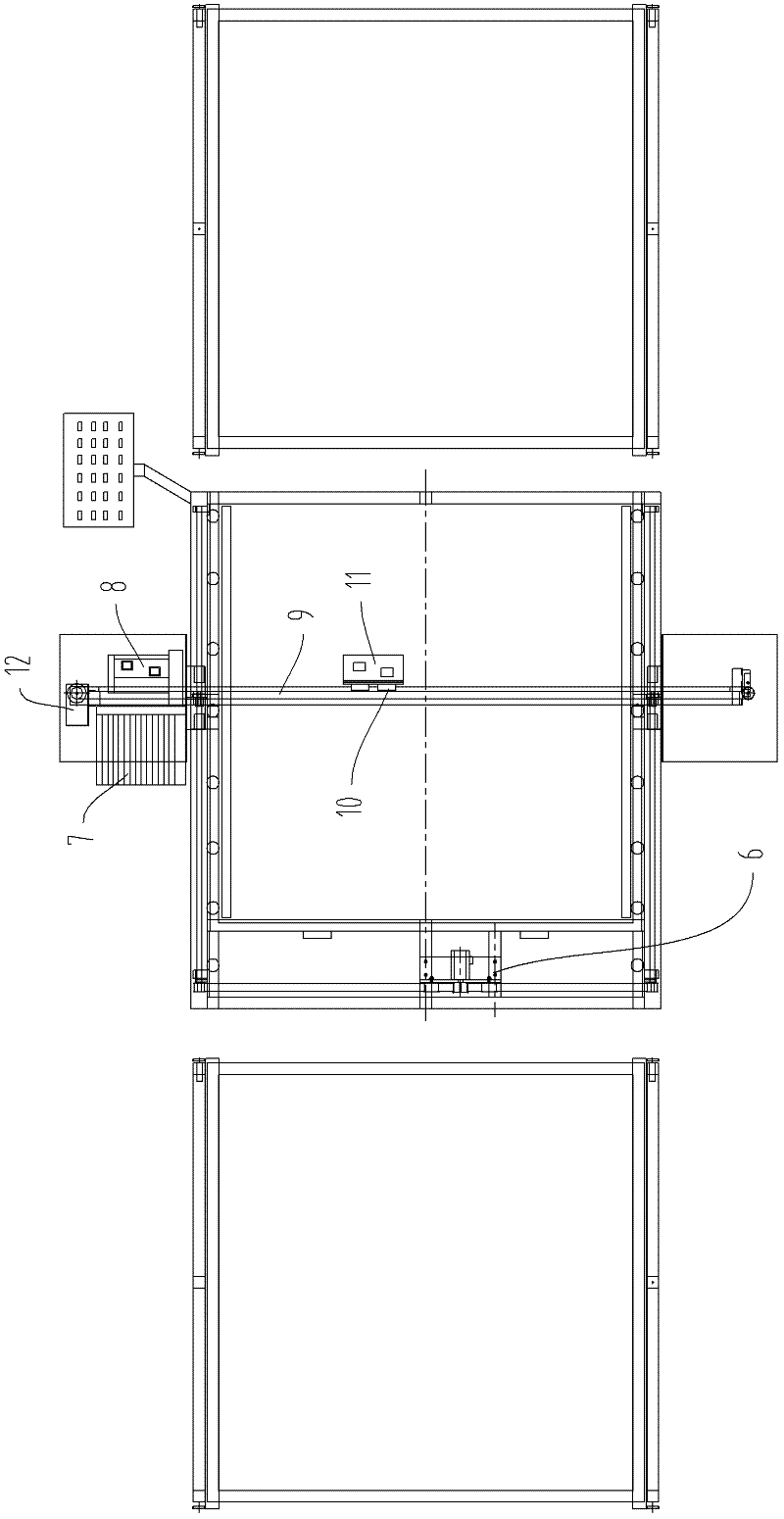

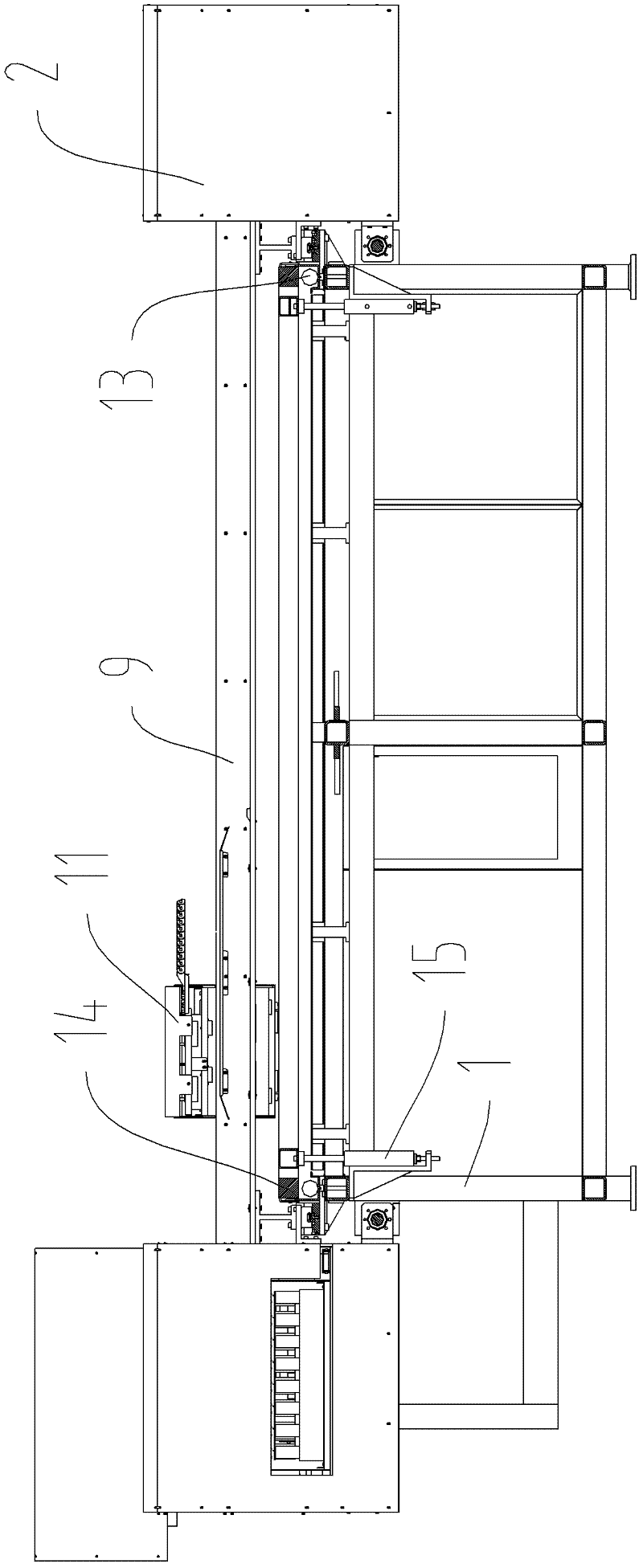

[0017] see Figure 1-3 The continuous flatbed printing device includes a frame 1, and two supports 2 are arranged on both sides of the frame longitudinally sliding through two guide rails 3. Two lead screws 4 are rotated on the frame below the two supports, and the nuts 5 that cooperate with the lead screws are fixed on the supports; The main drive mechanism 6 is connected.

[0018] An ink stack 7 and an ink-absorbing seat 8 are arranged on the support on the left side, and the guide rails 9 extending in the transverse direction are connected between the two supports. The seat is provided with a dolly driving device 12 that drives the printing dolly to move along the guide rail.

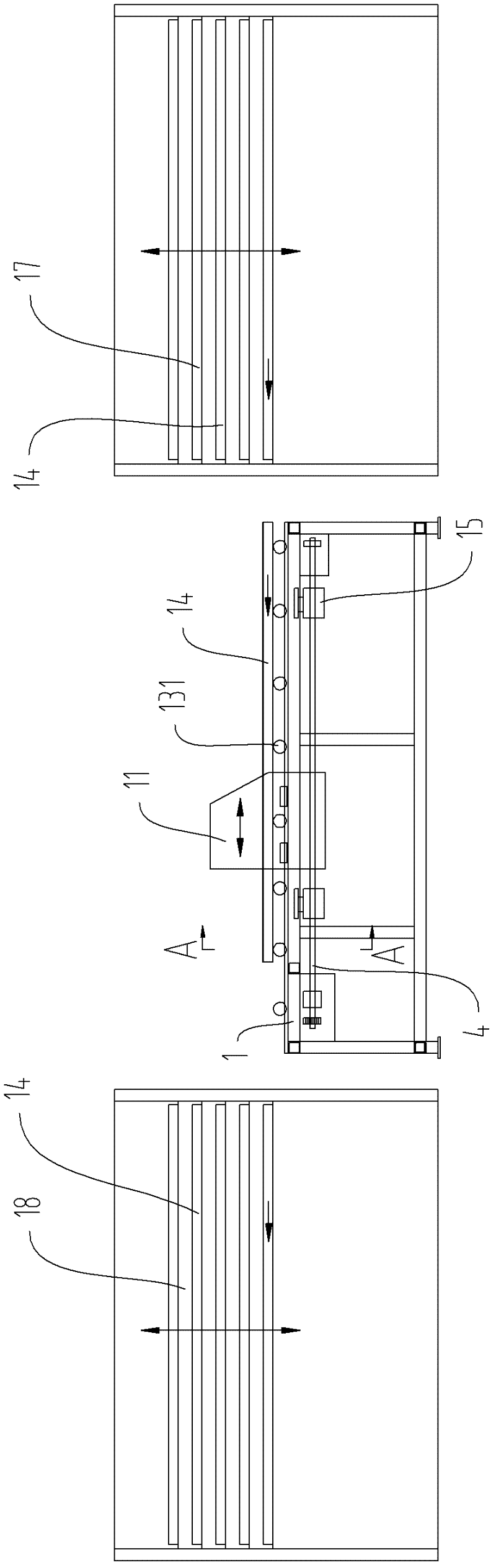

[0019] Two slide rails 13 extending longitudinally are arranged on both sides of the frame, and each slide rail is composed of a plurality of rolling balls 131 arranged on the frame. The upper surface can be provided with a rectangular printing platform 14 for printing media, which is slidably arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com