A method for preparing ion-type pressure array sensors based on 3D printing

An array sensor and 3D printing technology, applied in the field of 3D printing, can solve problems such as complex process, popularization and utilization of unfavorable materials, and difficult preparation of array sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1) Solution configuration;

[0049] Use a graduated cylinder to measure the Nafion solution 40ml and 10ml of dimethylacetamide (DMAC) with a mass fraction of 5% to mix, and magnetically stir and heat to concentrate until the concentration of Nafion is 40%;

[0050] 2) Planix gel configuration;

[0051] Weigh 4g of F-127 white powder, dissolve it in 6g of water, use a planetary mixer to stir evenly into a transparent gel, use a print head for preliminary inspection, the gel can be extruded into a uniform filament;

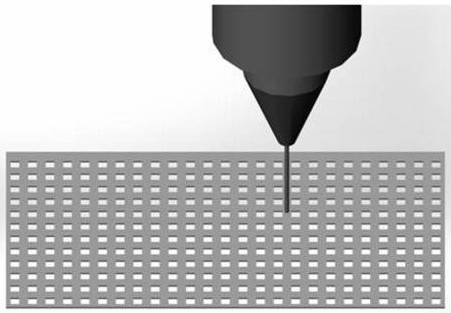

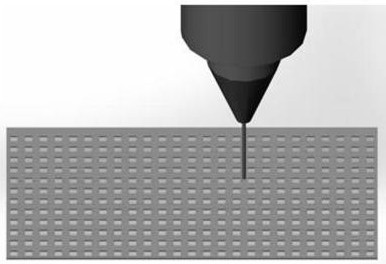

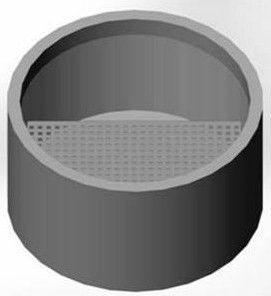

[0052] 3) Composite printing process;

[0053] S301, first load the ion polymer ink and F127 gel into the direct-writing printer with double nozzles, and adjust the extrusion air pressure for printing the ion polymer ink and F127 respectively, so that the nozzles can evenly discharge filaments;

[0054] S302, run the G code of the array model, the printer parameters are set to a layer thickness of 0.25mm, a scanning speed of 35mm / s, and an extrusion pressur...

Embodiment 2

[0060] 1) Solution configuration;

[0061] Use a graduated cylinder to measure 20ml of Nafion solution and 10ml of dimethylformamide (DMF) with a mass fraction of 5% and mix it with magnetic stirring, heating and concentrating until the concentration of Nafion is 60%.

[0062] 2) Planix gel configuration;

[0063] Weigh 3g of F-127 white powder, dissolve it in 7g of water, use a planetary mixer to stir evenly into a transparent gel, use a print head for preliminary inspection, the gel can be extruded into a uniform filament;

[0064] 3) Composite printing process;

[0065] S301, first load the ion polymer ink and F127 gel into the direct-writing printer with double nozzles, and adjust the extrusion air pressure for printing the ion polymer ink and F127 respectively, so that the nozzles can evenly discharge filaments;

[0066] S302, run the G code of the array model, the printer parameters are set to a layer thickness of 0.165mm, a scanning speed of 5mm / s, and an extrusion pr...

Embodiment 3

[0072] 1) Solution configuration;

[0073] Use graduated cylinder to measure the Nafion solution 10ml and 10ml of ethylene glycol (DMF) with a mass fraction of 5% and mix, magnetic stirring, heating and concentration until the concentration of Nafion is 50%

[0074] 2) Planix gel configuration;

[0075] Weigh 3g of F-127 white powder, dissolve it in 7g of water, use a planetary mixer to stir evenly into a transparent gel, use a print head for preliminary inspection, the gel can be extruded into a uniform filament;

[0076] 3) Composite printing process;

[0077] S301, first load the ion polymer ink and F127 gel into the direct-writing printer with double nozzles, and adjust the extrusion air pressure for printing the ion polymer ink and F127 respectively, so that the nozzles can evenly discharge filaments;

[0078] S302, run the G code of the array model, the printer parameters are set to a layer thickness of 0.2mm, a scanning speed of 15mm / s, and an extrusion pressure of 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com