Quick air-drying device for camshaft

A camshaft, fast technology, applied in heating devices, dryers for static materials, drying, etc., can solve the problems of low automation and complex structure, achieve high automation, reduce labor intensity, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

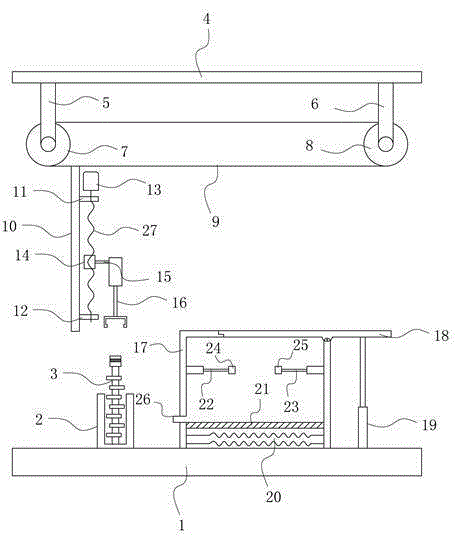

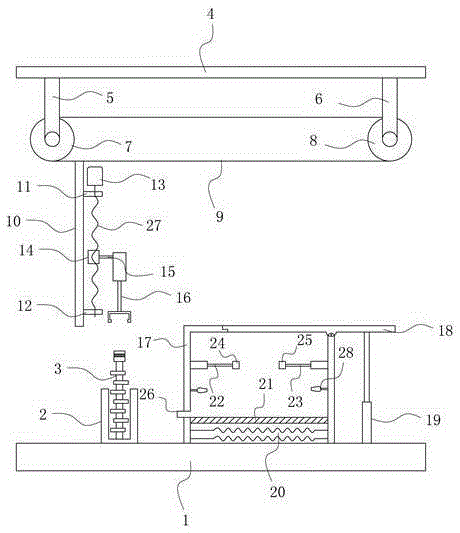

[0022] Both the left and right walls of the drying device 17 inboards are provided with fans 28 .

[0023] Base 1 right side lower end is provided with controller 29, and controller 29 is connected with electric gear 7, servomotor 13, thumb cylinder 16, extension cylinder 19, heating device 20, left cylinder 22, right cylinder 23 and blower fan 28 respectively.

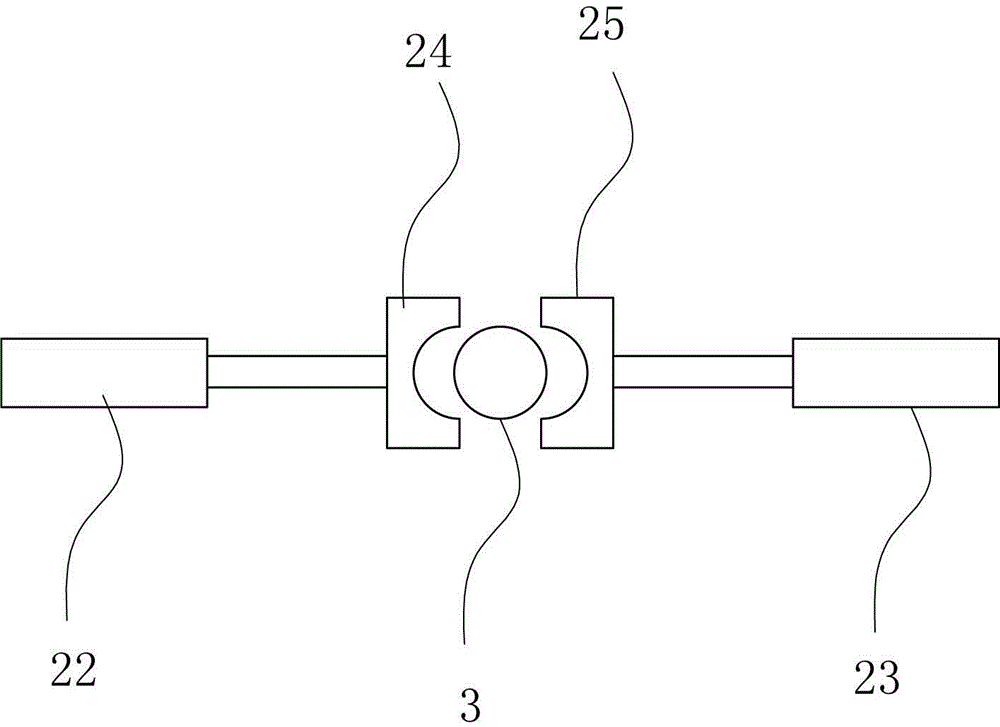

[0024] Working principle: The worker puts the cleaned camshaft 3 into the rack 2, the servo motor 13 drives the screw 27 to reverse, the nut 14 moves downward on the screw 27, and the nut 14 drives the thumb cylinder 16 through the connecting rod III 15 Moving downward, when the thumb cylinder 16 pushes against the camshaft 3, the servo motor 13 stops rotating, the thumb cylinder 16 clamps the camshaft 3, the servo motor 13 drives the screw 27 to rotate forward, and the nut 14 moves upward on the screw 27 , the nut 14 drives the thumb cylinder 16 to move upward through the connecting rod Ⅲ15, the electric gear 7 rever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com