Treatment method of high-salt and high-hardness organic wastewater in fly ash landfill

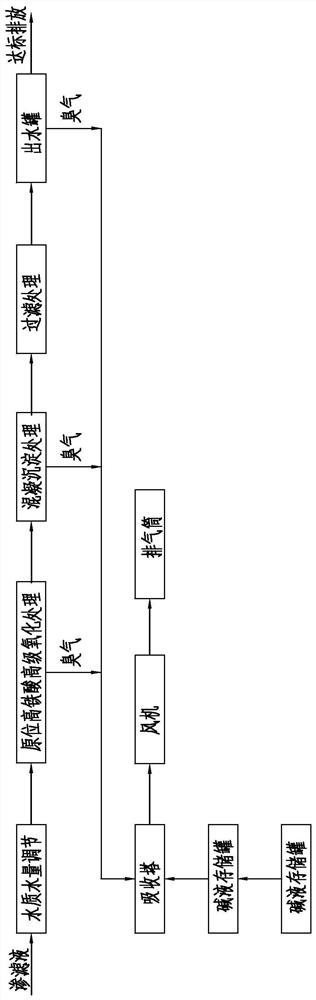

A technology of organic wastewater and treatment methods, applied in water/sewage treatment, adsorption water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems of membrane tube blockage, poor sedimentation effect, high investment and maintenance costs, and achieve Guarantee stability and automation, and solve the effect of complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

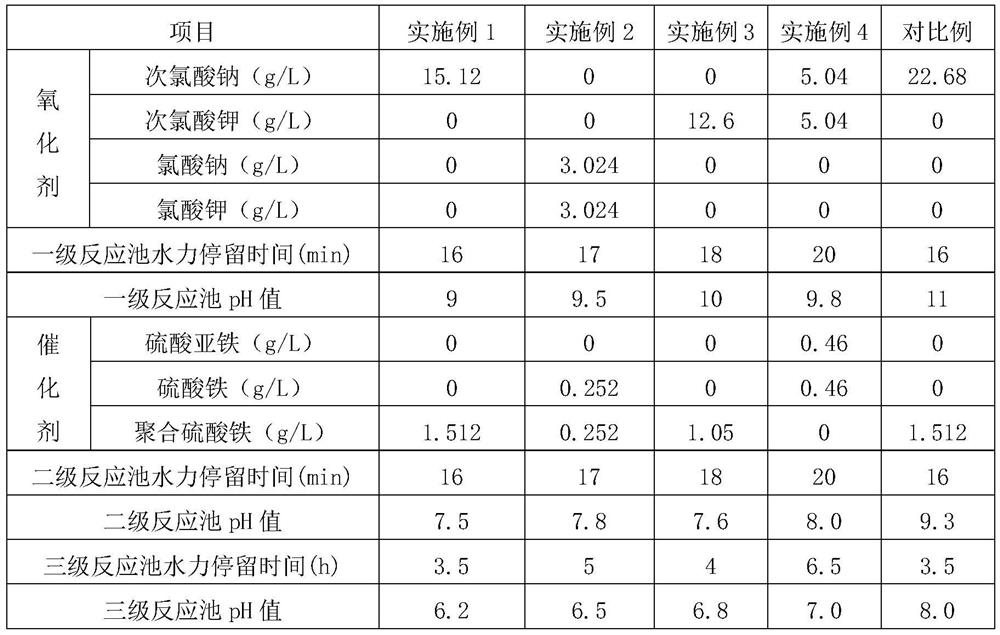

[0032] The fly ash landfill of a medical waste incineration plant in a certain place is divided into four reservoir areas, which are the main leachate water quality of the second phase south reservoir, the main leachate water quality of the second north reservoir, and the secondary leachate water quality and For the water quality of secondary leachate in the North Reservoir of Phase II, see Table 1 for specific parameters of water quality in each reservoir area.

[0033] Table 1 Unit: mg / L (except pH)

[0034] project CODcr Total Cadmium total lead chloride SS pH Water quality of the main leachate in the second phase of South Reservoir 2880 0.004 ND 85050 602 10.33 Phase II South Reservoir Leachate 3200 ND ND 90550 501 9.90 Water quality of the main leachate of the second phase North Reservoir 3960 ND 13.3 133350 507 11.28 Water quality of secondary leachate in North Reservoir Phase II 3620 ND 0.048 126900 48...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com