Automatic component insertion machine

An automatic plug-in machine and manipulator technology, applied in the direction of electrical components, electrical components, and electrical components to assemble printed circuits, can solve the problems of low degree of automation, low production efficiency, insufficient stability, etc., to improve the degree of automation, improve The efficiency of work, the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

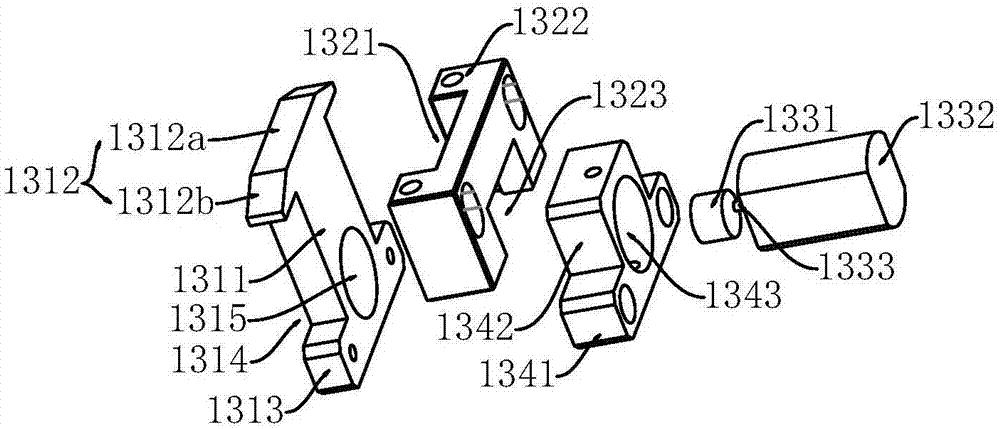

[0036] Please refer to the drawings in the accompanying drawings, wherein like reference numerals refer to like components. The following description is based on illustrated specific embodiments of the invention, which should not be construed as limiting other specific embodiments of the invention not described in detail herein.

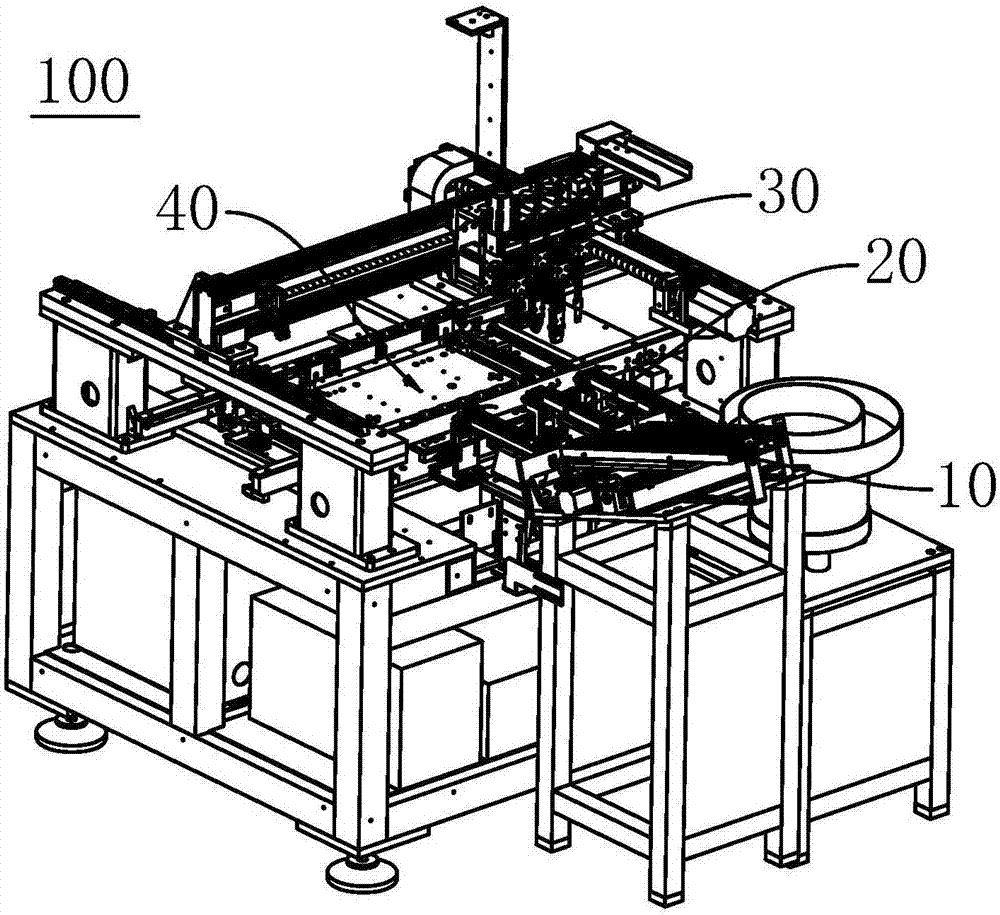

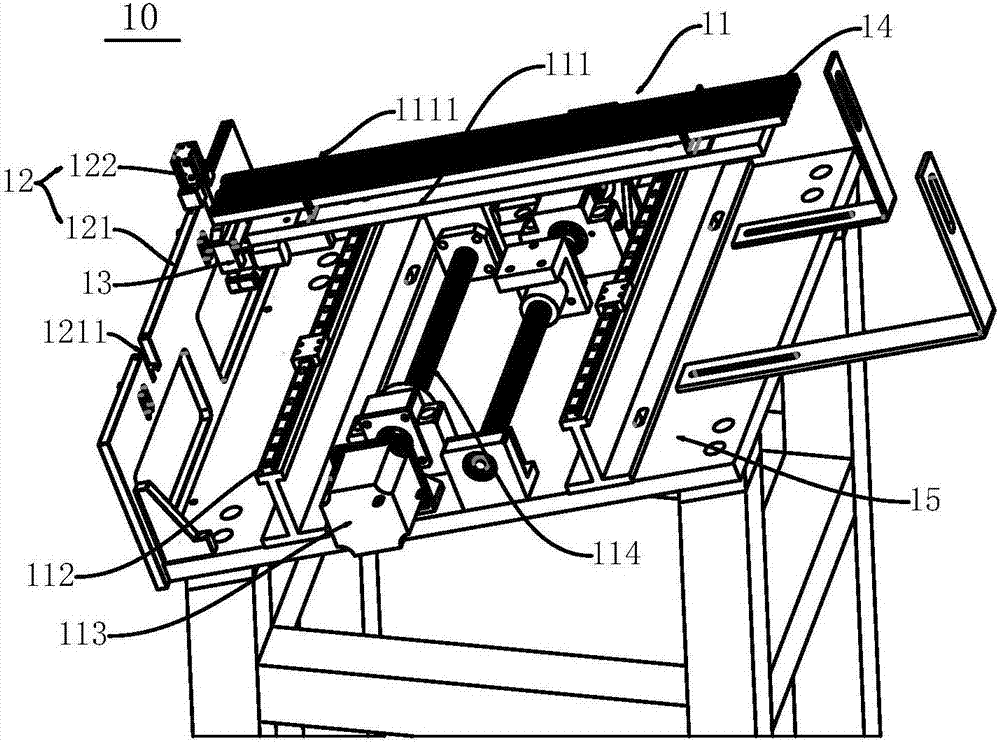

[0037] Please refer to figure 1 , figure 1 It is a structural schematic diagram of a preferred embodiment of the automatic plug-in machine of the present invention; the automatic plug-in machine 100 of the present invention includes a feeding device, a material transfer device 20, a plug-in manipulator device 30 and a PCB board transfer device 40, wherein the feeding device includes a tube Charge feeder 10 and bulk feeder.

[0038] The feeding device is used to provide materials, including a tube charging feeder 10 for providing tube charging and a bulk material feeder for providing bulk materials; the material transfer device 20 has a plug-in robo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com