Rotation type multi-station combination property auxiliary testing device of solenoid valve coil

A solenoid valve coil, comprehensive performance technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of low degree of testing automation, low testing accuracy, and high labor costs, to improve the degree of testing automation and market competition. The effect of saving energy and working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with drawings and embodiments.

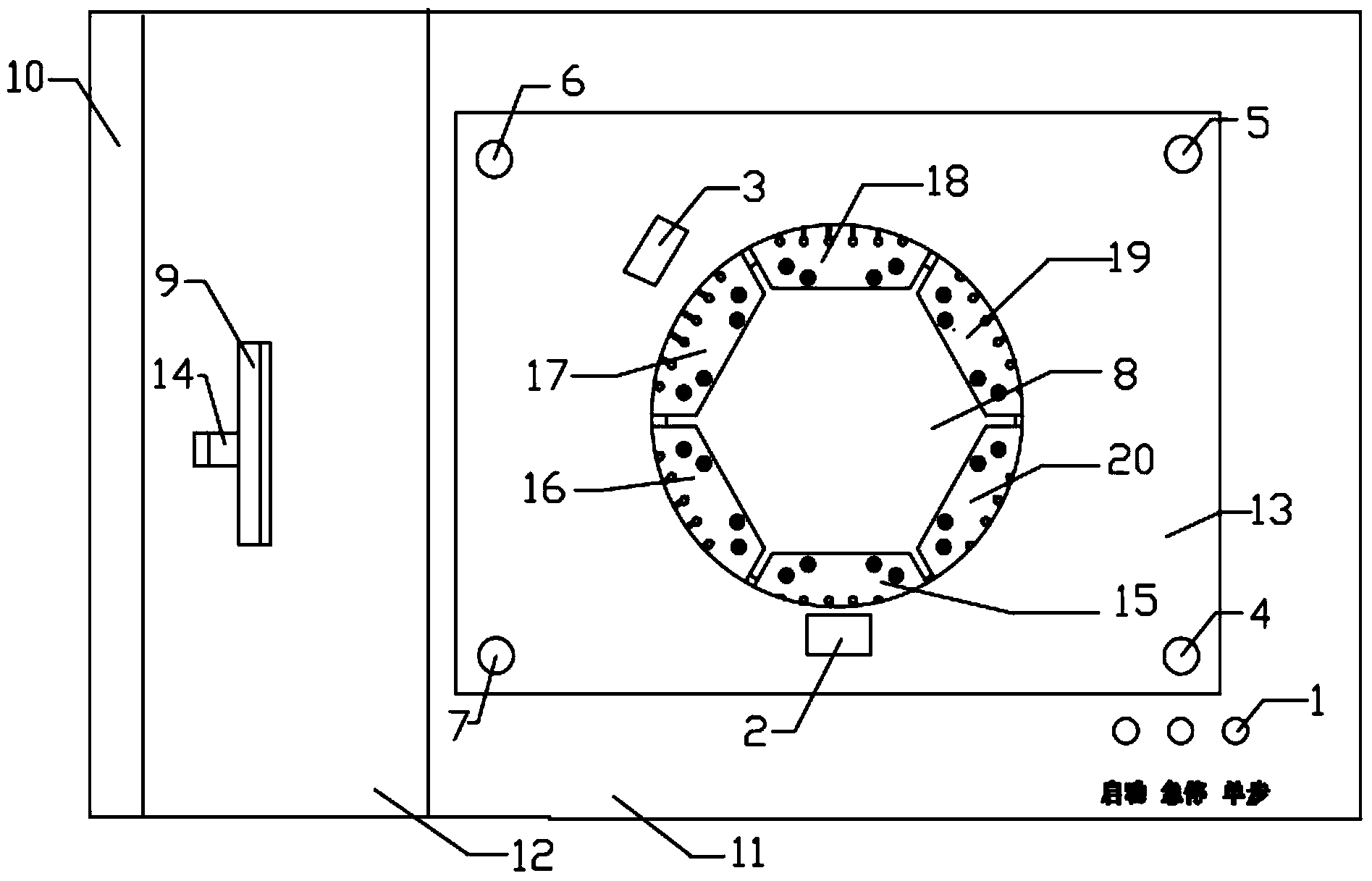

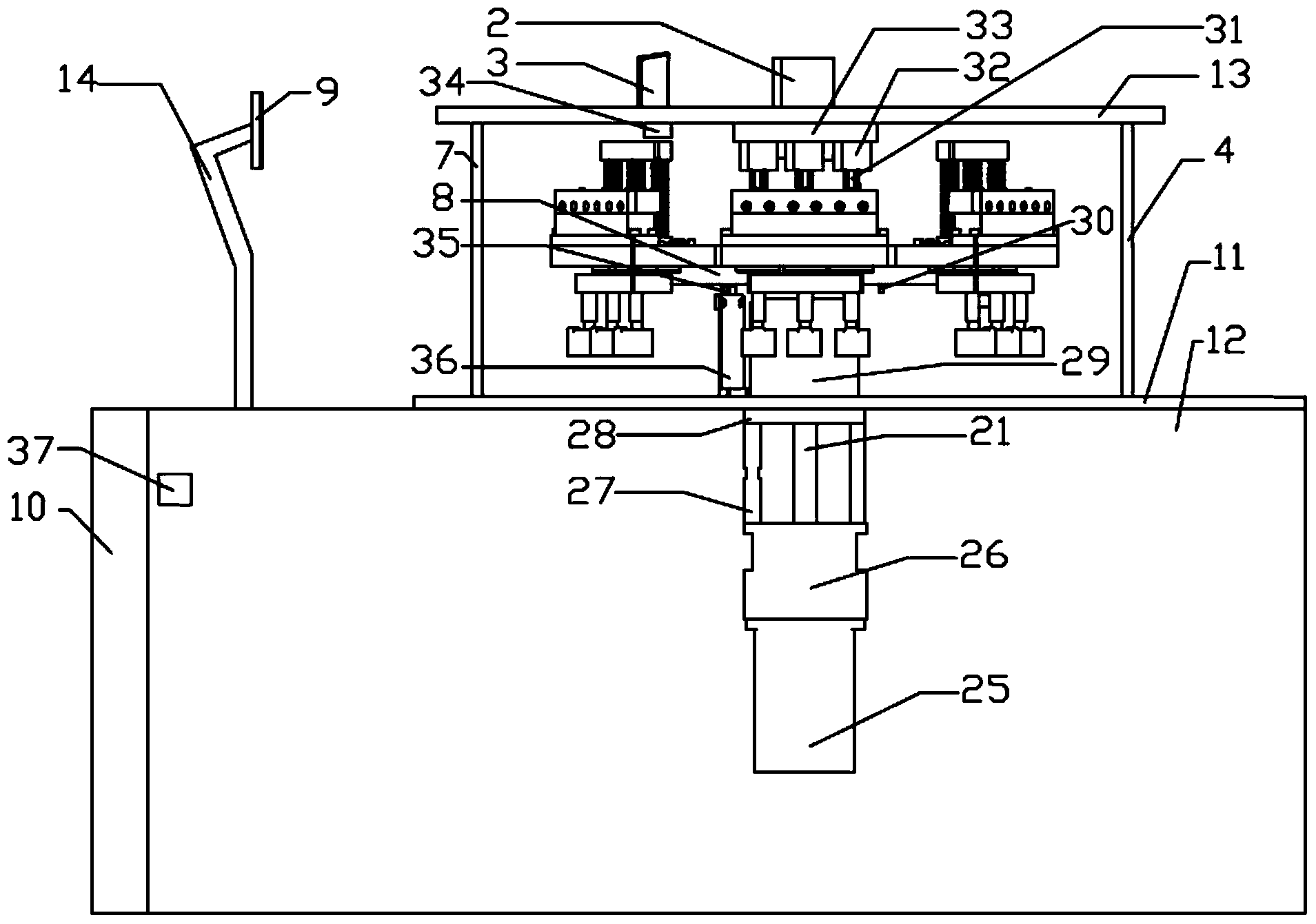

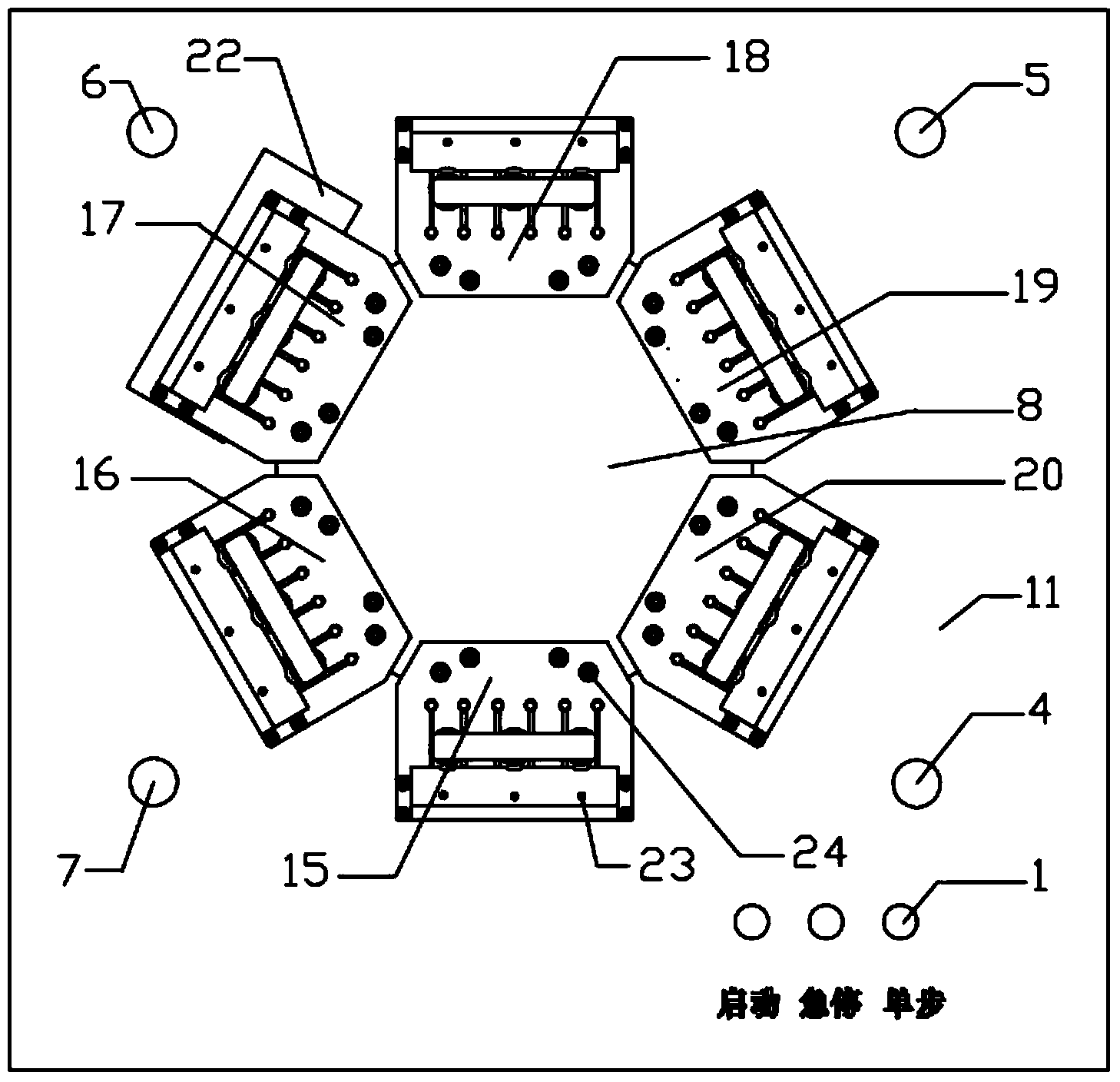

[0037] Such as figure 1 , figure 2 As shown, the device of the present invention includes a rotary table 8, a fixed base plate 11, a cabinet 12, a top plate 13, a rotating shaft 21, a stepper motor 25, a speed reducer 26, a support column 27, a first connecting block 28, a rotation support column 29, The blocking member 30 and the photoelectric switch 35; the electrical control cabinet 10 is installed on one side of the cabinet 12.

[0038]The cabinet 12 is provided with a fixed base plate 11, and the top plate 13 is connected with the fixed base plate 11 through the first column 7, the second column 6, the third column 5, and the fourth column 4 supported on the four corners. The center of the top plate 13 has a hole. The connecting block 28 is fixedly connected to the lower bottom surface of the fixed base plate 11, the lower end of the first connecting block 28 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com