Automatic network-arranging welding equipment

A technology of welding equipment and automatic rowing, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low automation of welding machinery and low production efficiency, and achieve high stability of net discharge welding, net discharge welding Fast speed, solve the effect of low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

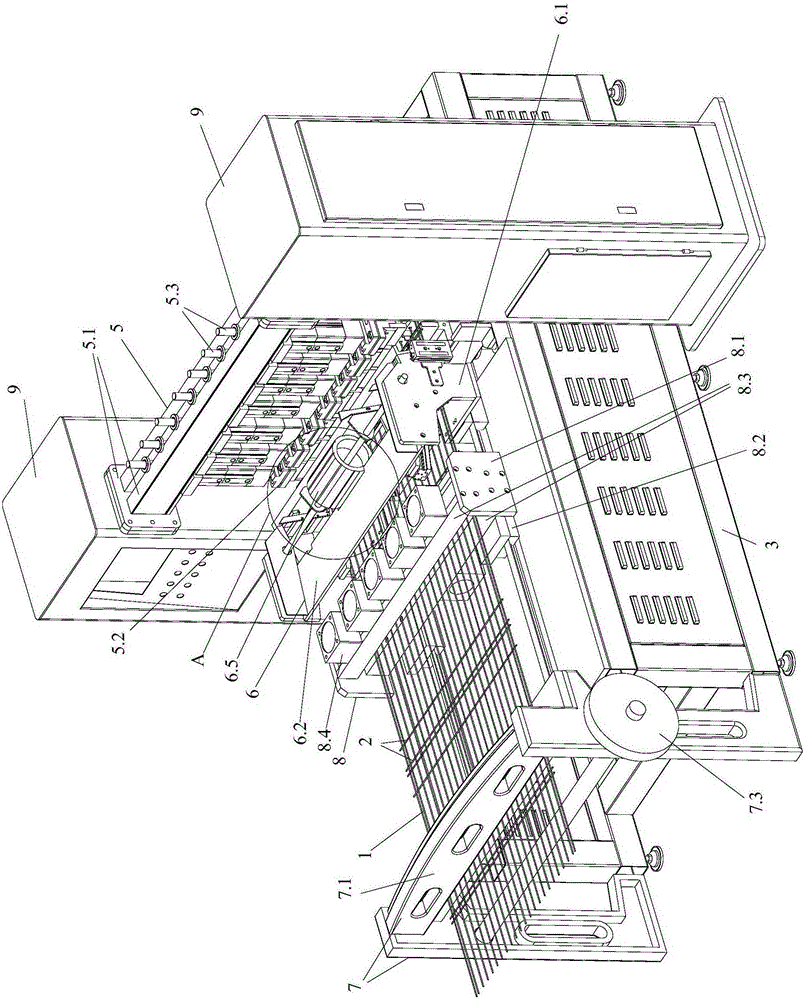

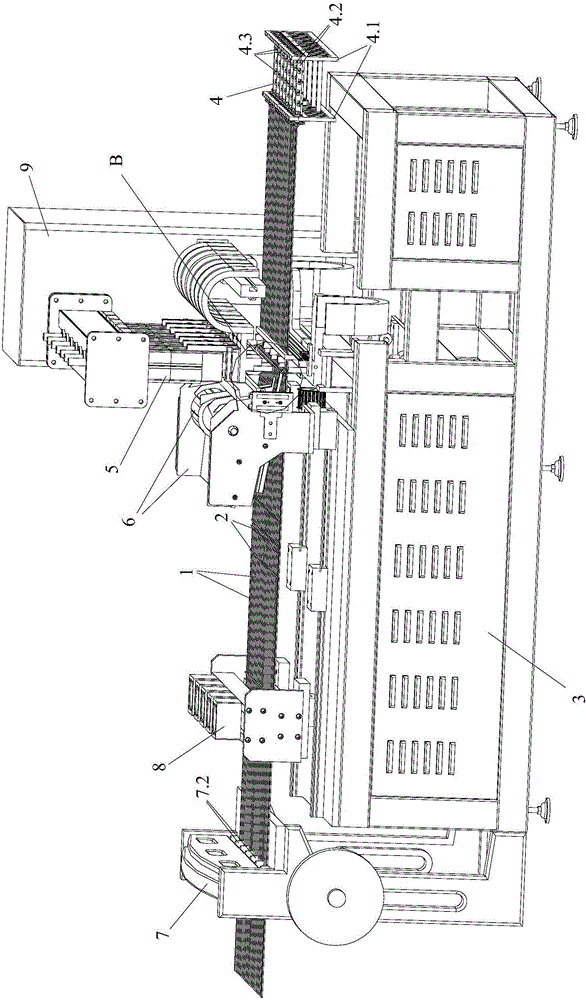

[0037] Such as Figures 1 to 5 As shown, the present invention is an automatic screen welding equipment, which is used to arrange and weld the longitudinal wire 1 and the horizontal wire 2 to form a wire mesh; it includes:

[0038] Rack 3;

[0039] The longitudinal mesh arrangement mechanism 4 arranged at the front end of the frame 3 is used to straighten and arrange the longitudinal mesh 1;

[0040] The welding mechanism 5 straddling the frame 3 is used to weld the horizontal mesh 2 and the longitudinal mesh 1 to form a wire mesh;

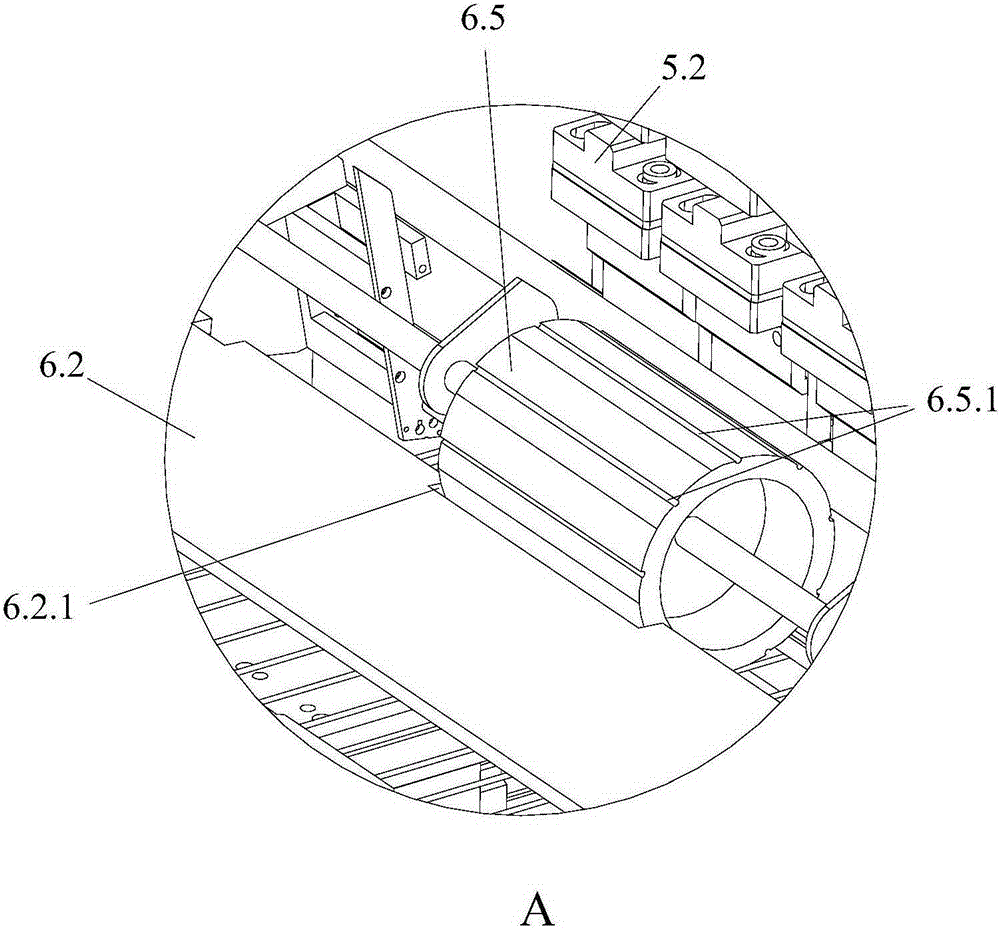

[0041] The horizontal wire unloading mechanism 6 straddling the frame 3 and arranged on one side of the welding mechanism 5 is used to transport the horizontal mesh 2 to the welding station of the welding mechanism 5 and position it;

[0042] The cutting mechanism 7 arranged at the rear end of the frame 3 is used to cut the wire mesh formed by welding;

[0043] A wire drawing mechanism 8 connected to the frame 3 is used to clamp the mesh and pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com