Electronic expansion valve rotary type multiple stations integration testing device

An electronic expansion valve and comprehensive testing technology, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of low overall testing efficiency, time-consuming installation of test pieces, and time-consuming replacement of fixtures, etc., to achieve Improve the degree of test automation, improve market competitiveness, and save working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

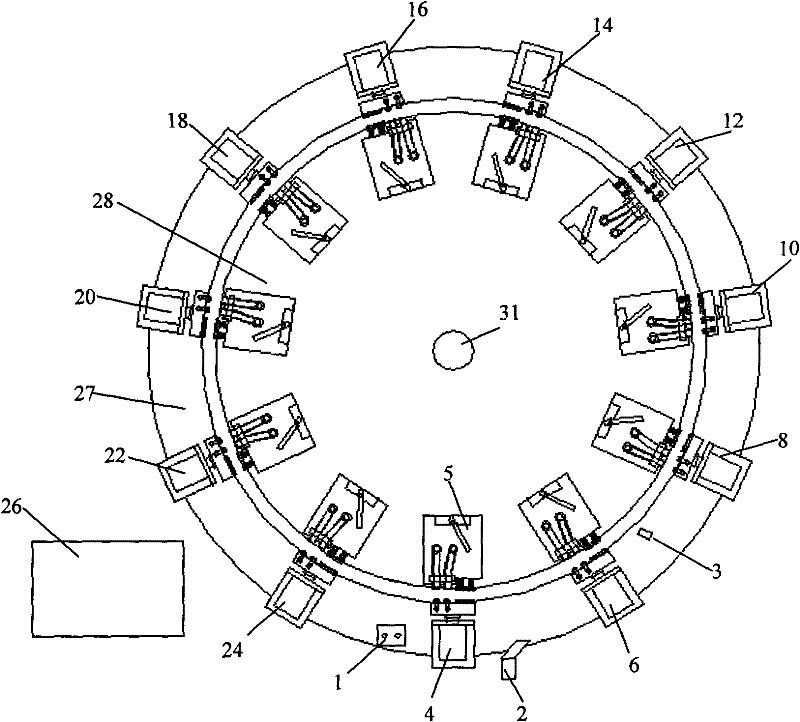

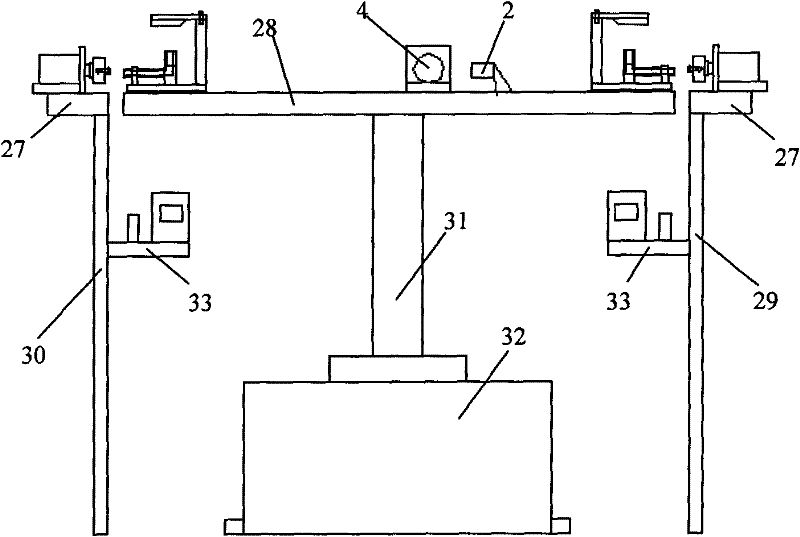

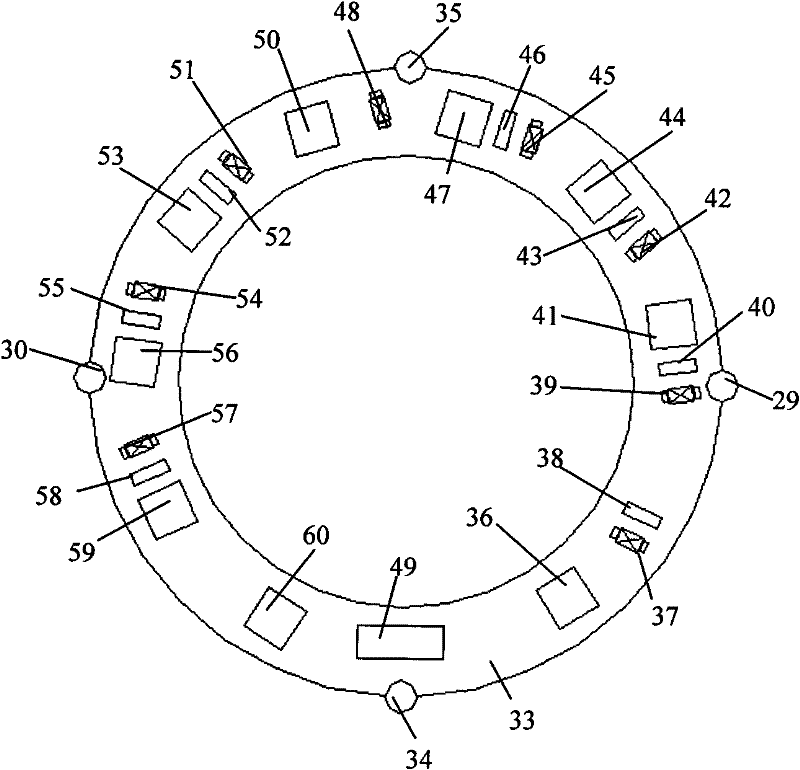

[0026] Such as figure 1 , figure 2As shown, the device adopts a circular rotary workbench 28, the peripheral ring part of the workbench surface is a fixed workbench 27, and the fixed workbench 27 is supported on evenly distributed first columns 34, second columns 29, and third columns 35. 1. On the fourth column 30, the control cabinet 26 is arranged on the left side of the fixed workbench 27, and the fixed workbench 27 is evenly distributed counterclockwise from the first column 34 to install the valve loading and unloading station 4, the valve closing station 6, and the flow rate of the valve closing Measuring station 8, the first station for valve opening point measurement 10, the second station for valve opening point measurement 12, no-load flow measurement station 14, high pressure valve opening station 16, load flow measurement station 18, small flow measuremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com