Automatic lamination robot for transformer iron core

A transformer core and robot technology, which is applied in the manufacture of inductors/transformers/magnets, manipulators, program-controlled manipulators, etc., can solve the problems of low efficiency of transformer core lamination process, low degree of automation, light labor and high intensity, etc. Achieve the effect of realizing on-duty operation, improving stacking quality and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

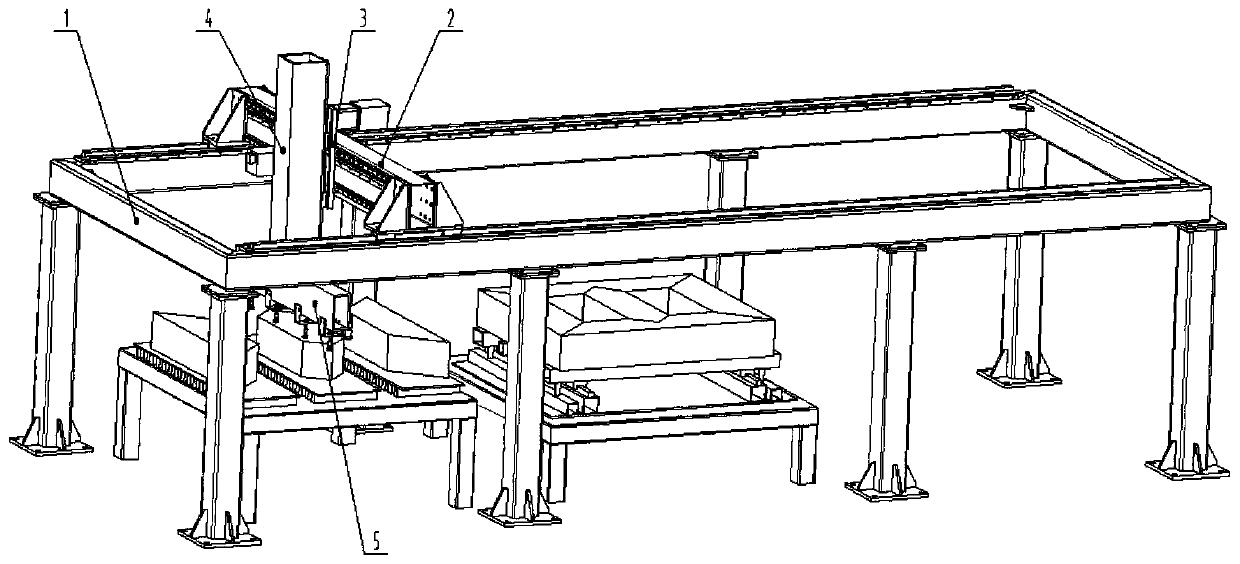

[0044] Such as Figure 1-Figure 12 As shown, a machine vision-based automatic lamination robot for transformer cores described in this example includes a main frame 1, a large beam assembly 2, a lateral movement assembly 3, a longitudinal movement assembly 4, and a rotation assembly 5 , The control module is set in the control cabinet;

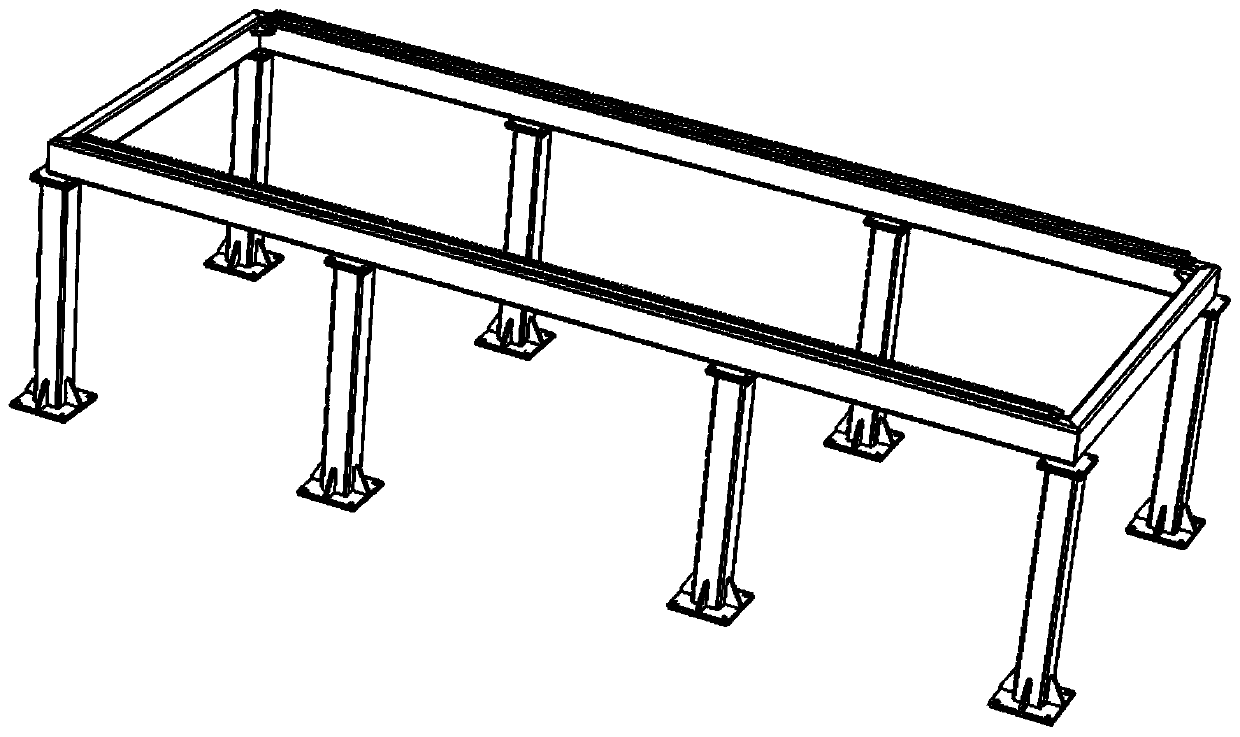

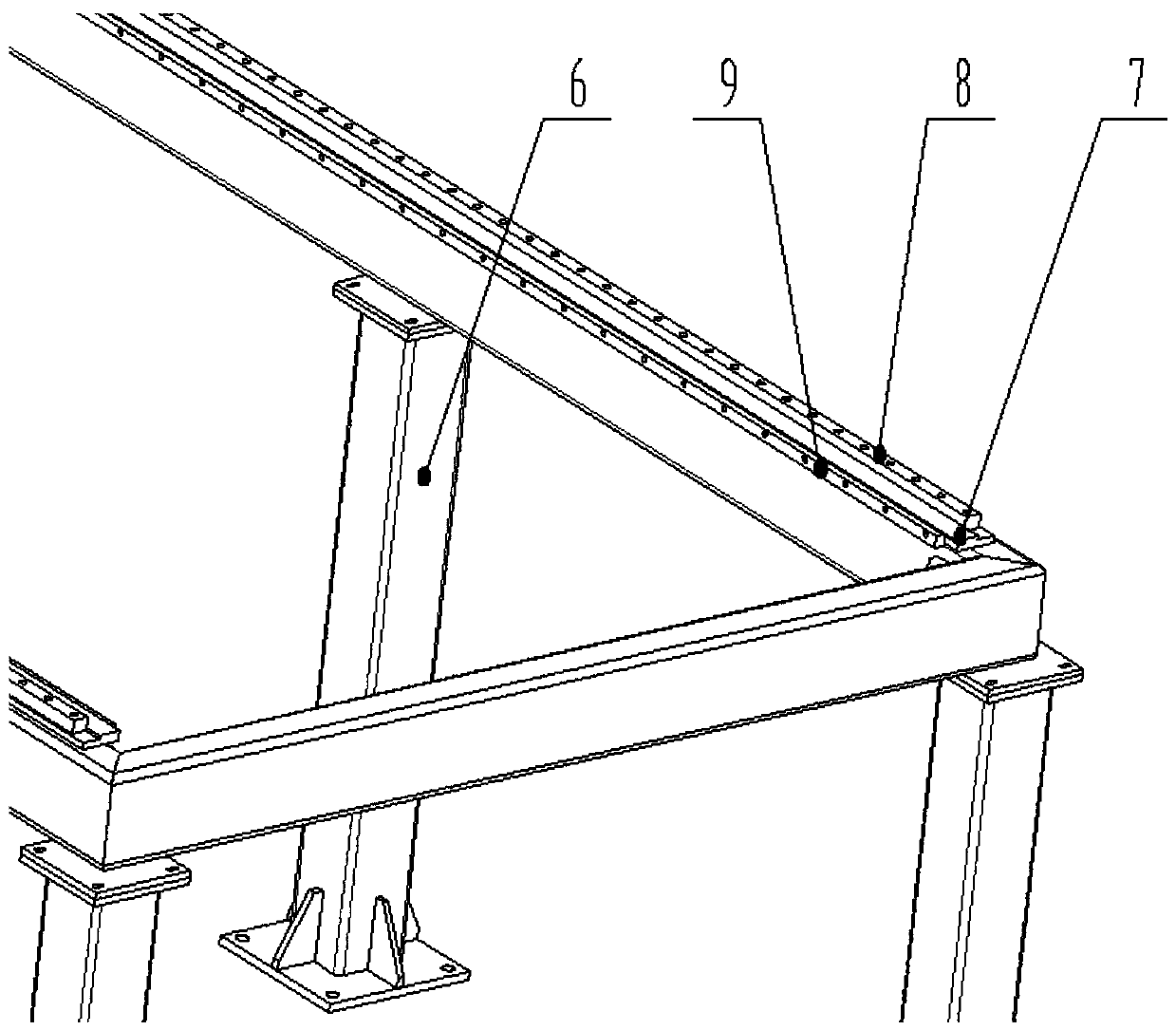

[0045] In the main frame assembly 1, there are eight columns 6 to support the whole system, and two sets of rail pads 7 are installed on the left and right sides above the main frame 1 to fix the linear guide rails...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com