Method used for manufacturing ITO heating plate for large-area LCD screen

A technology of LCD screen and manufacturing method, applied in nonlinear optics, instruments, optics, etc., can solve the problems of low edge temperature, heat accumulation, and high temperature in the middle of the panel, so as to prolong the working life, uniform temperature field distribution, and work effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

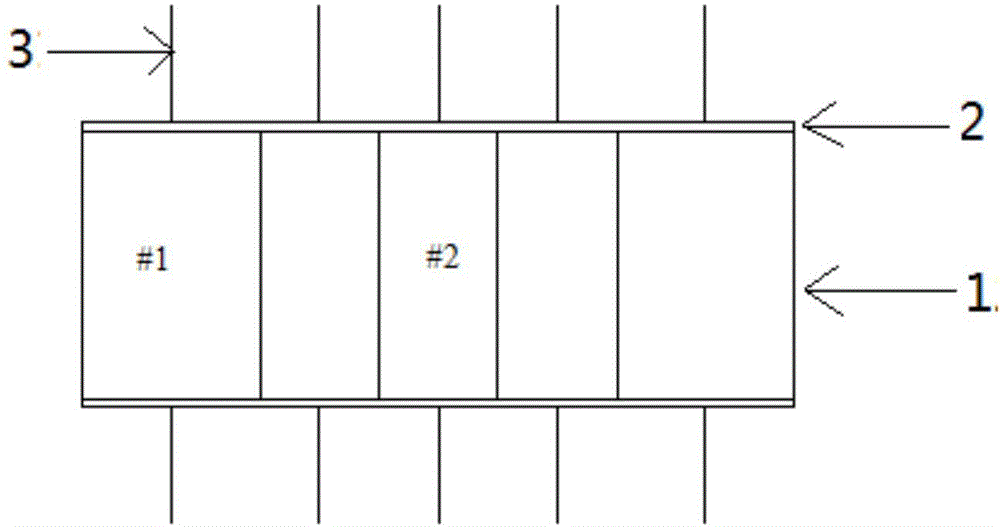

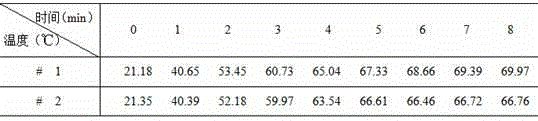

[0022] like figure 1 , 2 As shown, a method for manufacturing an ITO heating sheet for a large-area LCD screen is characterized in that it is designed in a partitioned heating manner, and the entire ITO substrate is partitioned according to a certain area ratio by etching, and the ITO The size of the substrate is 9 inches × 24 inches, and the area ratio of the partition is 6:4:4:4:6, which specifically includes the following steps:

[0023] (1) Cleaning: First, clean the ITO substrate in an ethanol solution containing 4% KOH, then clean it with 95% ethanol, and finally rinse it with secondary water. After washing, place it in the air to dry naturally ;

[0024] (2) Coating photoresist: After evenly coating a layer of photoresist on the ITO substrate, put it in an oven and bake at 90-100°C for 25-30min;

[0025] (3) Exposure: The light emitted by the exposure machine is irradiated on the photoresist (RZJ-304) through the mask plate, and a photochemical reaction occurs; the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com