Cage-type heating unit for crystal growth

A heating device and crystal growth technology, applied in crystal growth, single crystal growth, post-processing devices, etc., can solve problems such as difficulties, and achieve the effect of improving heating efficiency and uniform temperature field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further described below in conjunction with embodiment; The following embodiment is not for the limitation of the present invention, only as the mode of supporting the realization of the present invention, any equivalent structural replacement within the technical framework disclosed in the present invention, all is the present invention. the scope of protection of the invention;

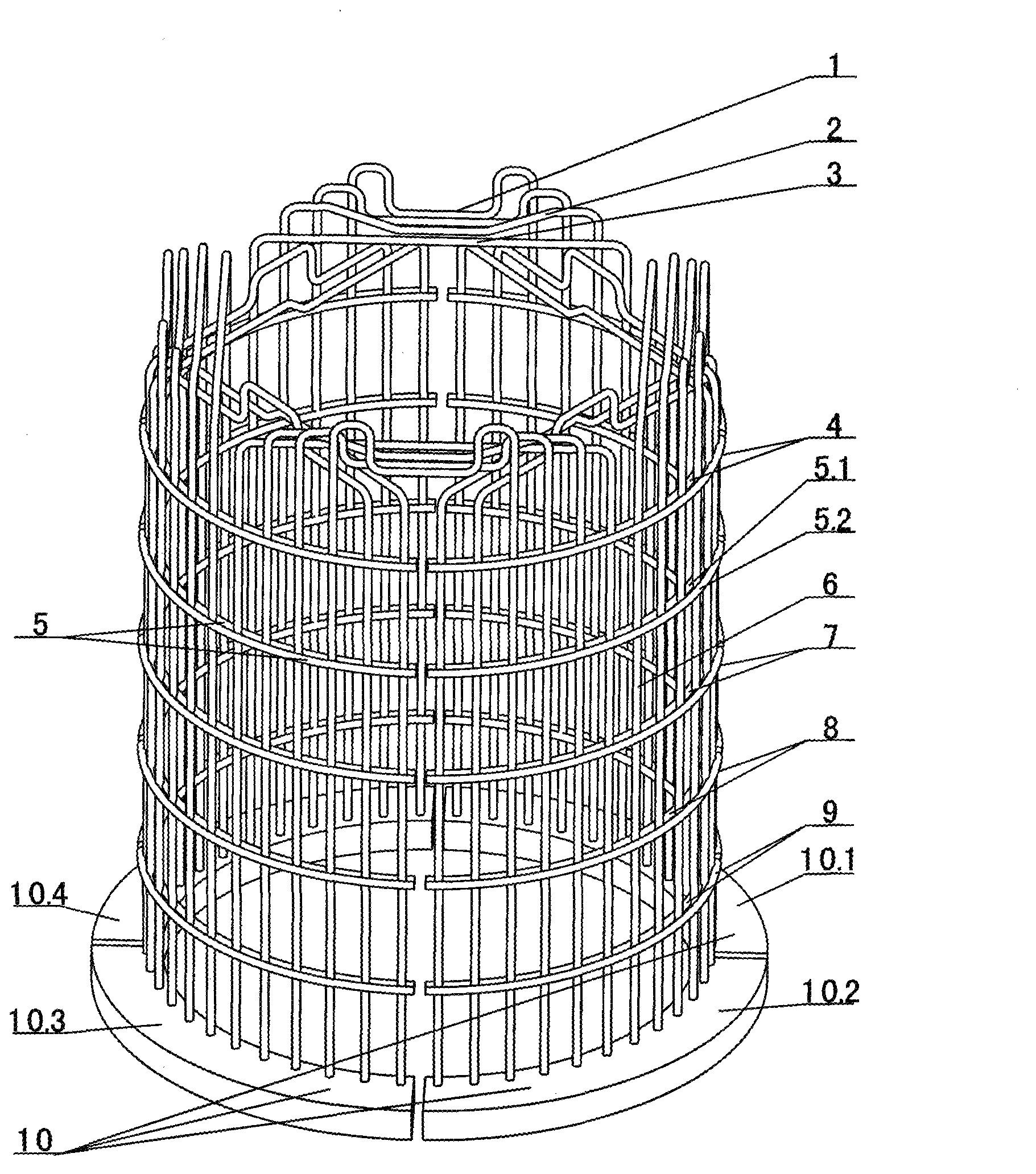

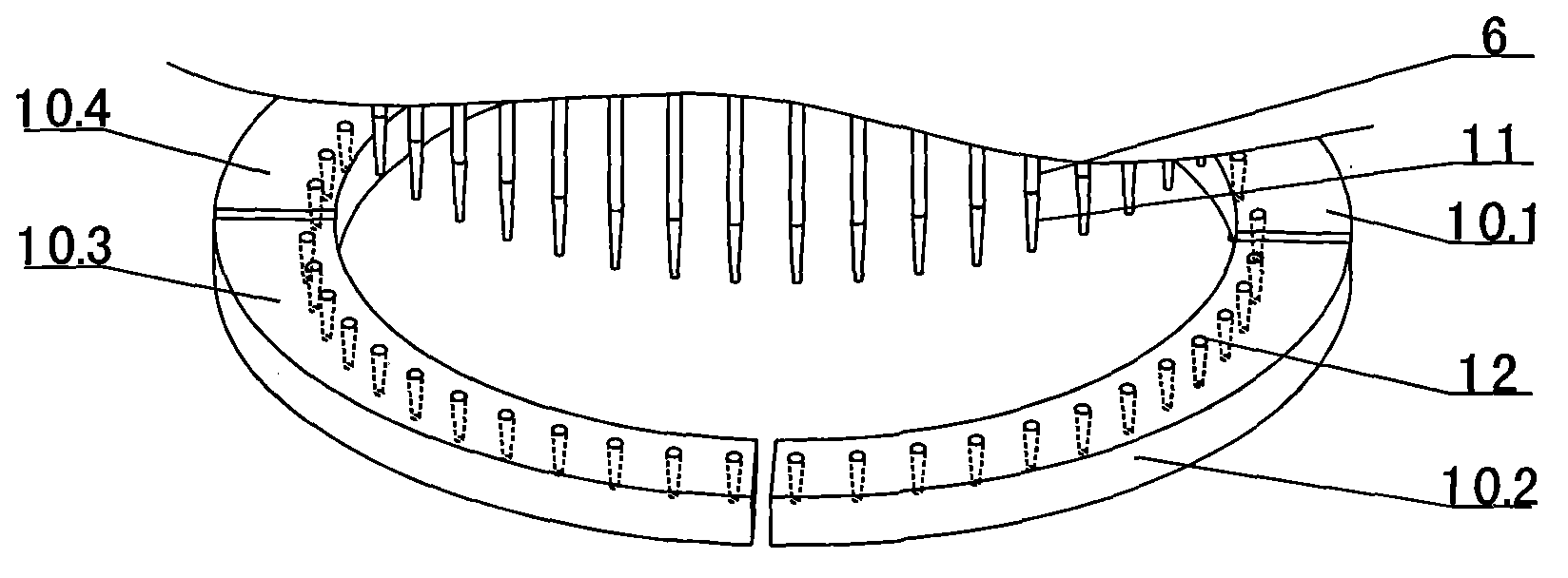

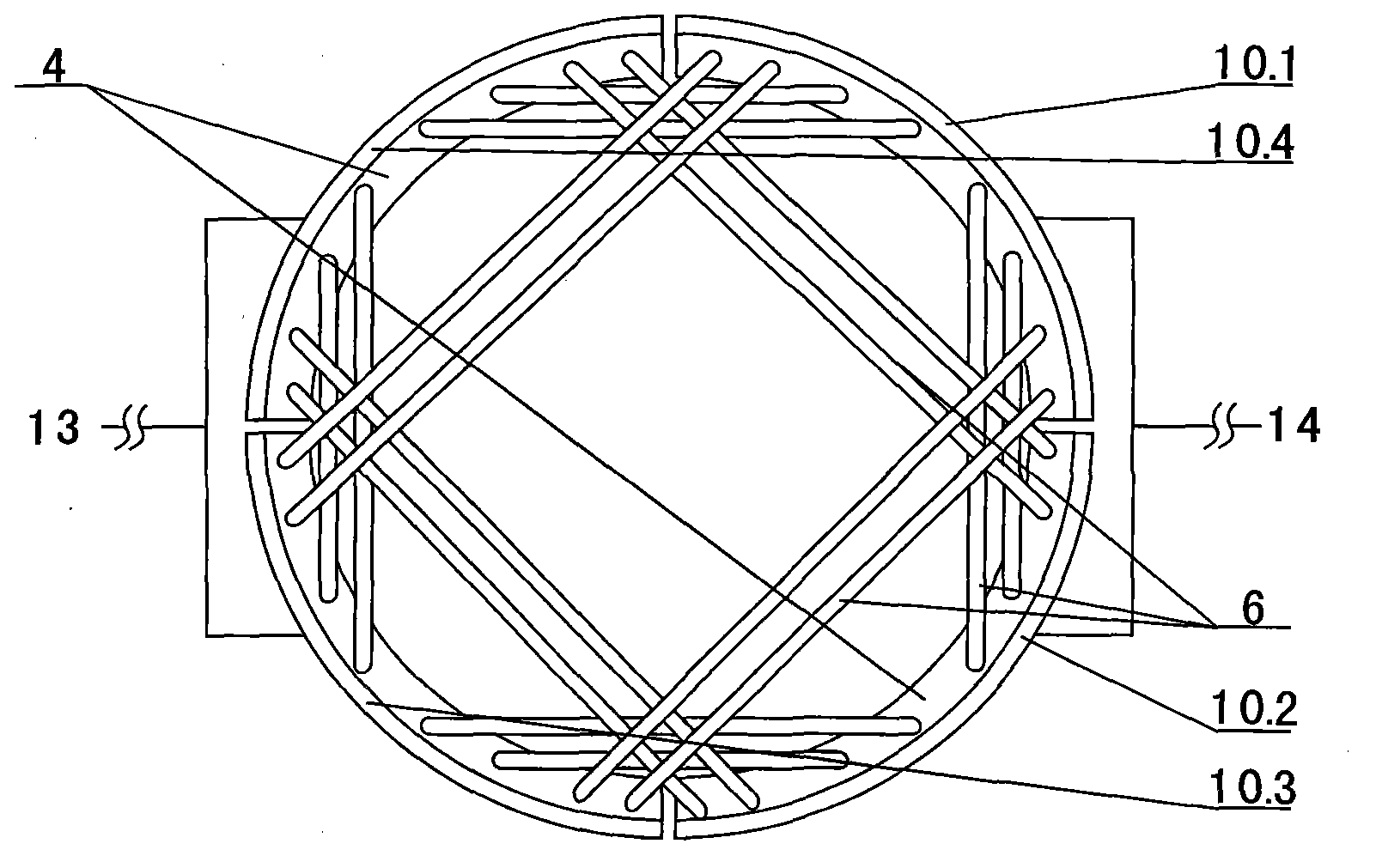

[0024] combined with Figure 1~5 Provided in the cage heating device for crystal growth, the invention is attached figure 1 A form is given for the base 10, that is, the base 10 is composed of four quarter circles; that is, the first quarter base 10.1, the second quarter base 10.2, and the third quarter circle The base 10.3 and the fourth quarter base 10.4; a full circle is formed by the aforementioned four quarter circles, but the full circles formed by the four quarter circles are spaced from each other, corresponding to four The upper part of the quarter circle i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com