Production process for integrated solar cell with diodes and manufacturing method for photovoltaic assembly

A technology for solar cells and production processes, applied in final product manufacturing, electrical components, sustainable manufacturing/processing, etc., can solve the problems of poor battery volt-ampere characteristic curve, complicated welding process, unsightly appearance, etc., and prolong the service life. , The effect of solving the hot spot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

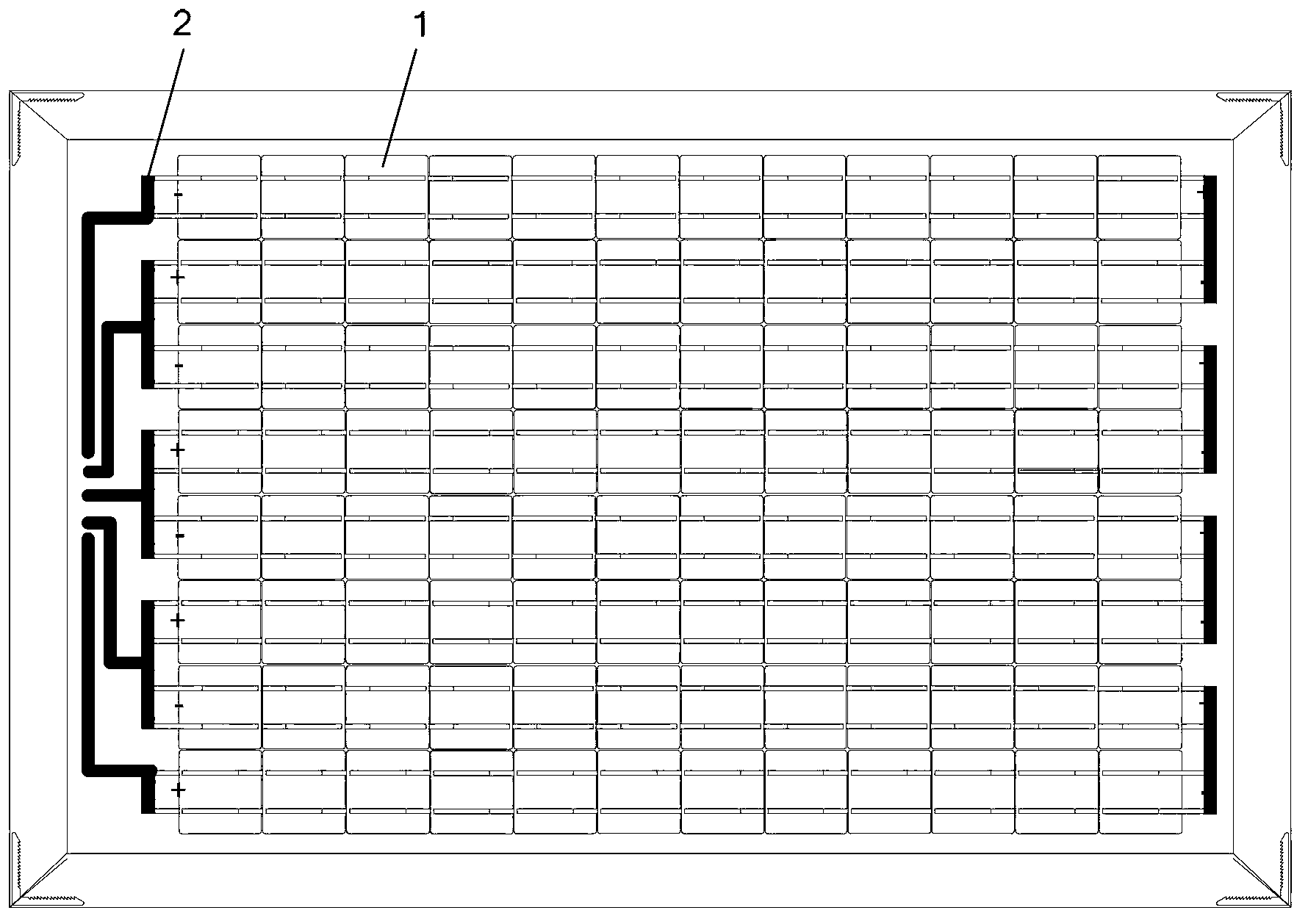

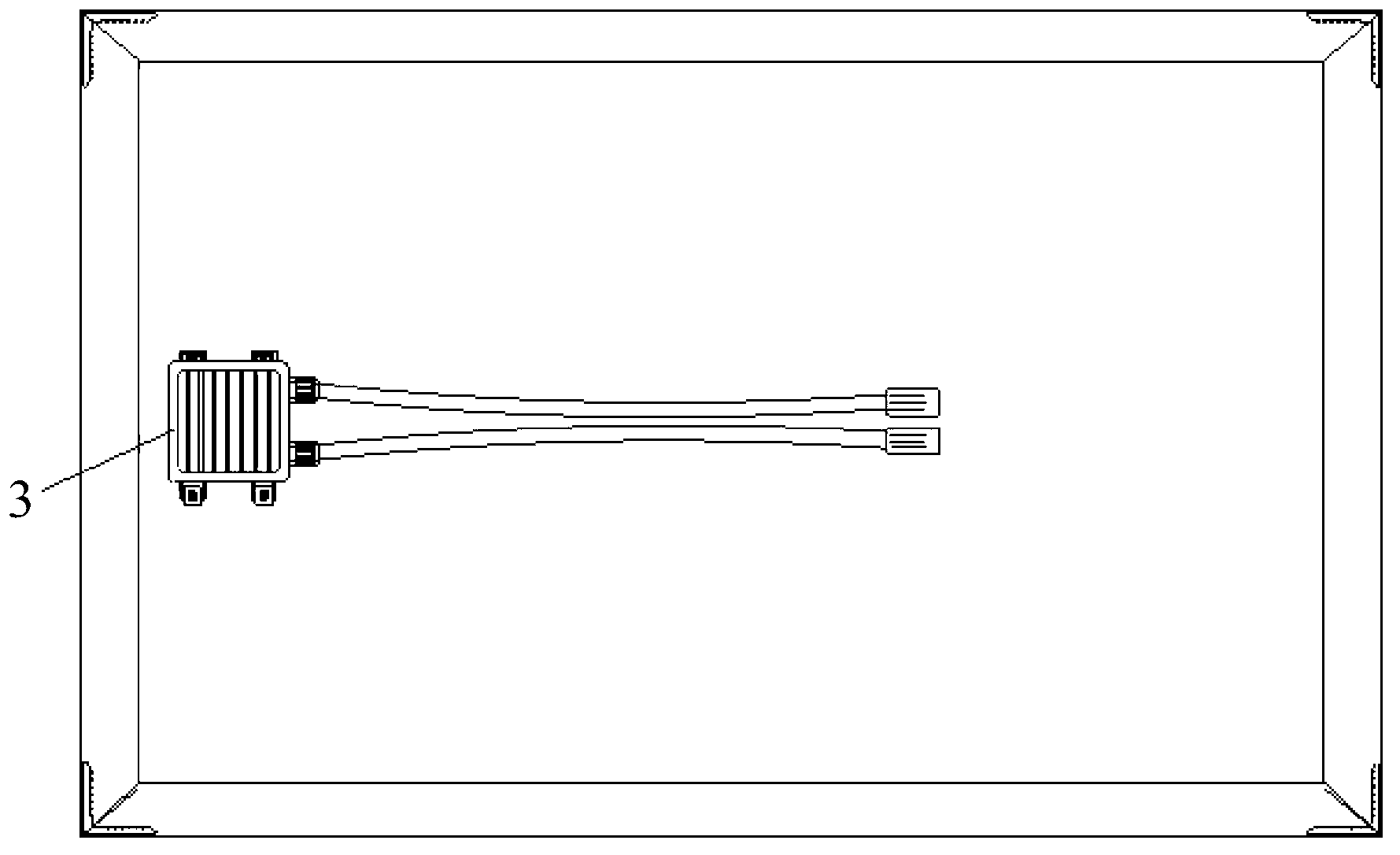

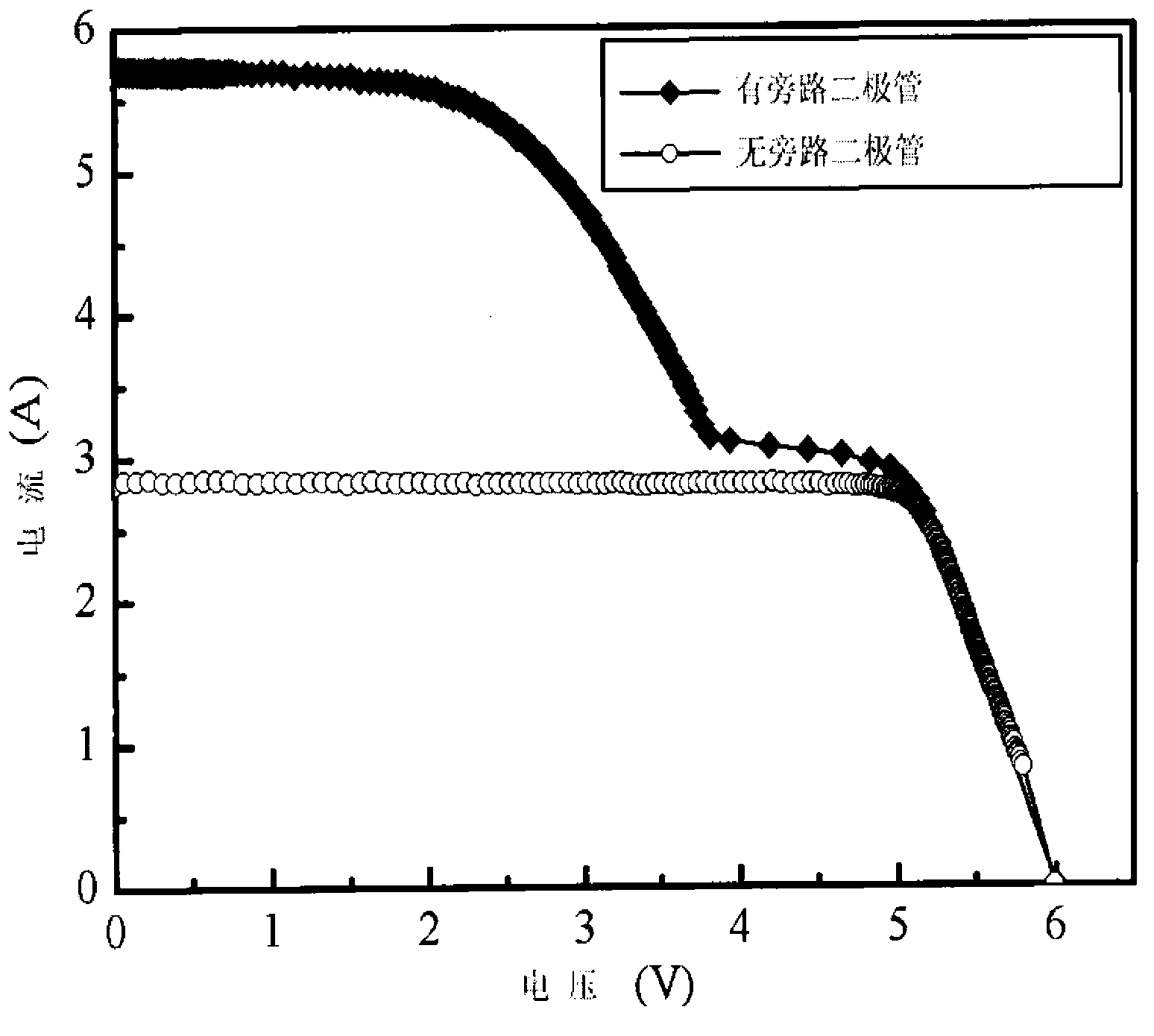

[0077] The invention discloses a production process of a solar battery with integrated diodes, which avoids the influence of bypass diodes on the light-receiving area of the solar battery, has good volt-ampere characteristic curves, and completely solves the hot spot effect of the solar battery.

[0078] On the basis of the above-mentioned production process of solar cells with integrated diodes, the present invention also discloses a method for manufacturing photovoltaic components, so as to improve power generation efficiency, reduce power generation losses and prolong the operating life of the components.

[0079] In order to better understand the technical solution of the present invention, the terms relevant to this case are now explained as follows:

[0080] Photovoltaic module: also called solar cell module and solar panel, it is a photovoltaic power generation product that converts solar energy into electrical energy, and is the core part of a solar power generation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com