Blending type LED backlight

A LED backlight, hybrid technology, applied in the field of LED backlight, can solve the problems of low utilization rate of light source, waste of energy, etc., and achieve the effect of high utilization rate of light source, saving energy, and increasing the separation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments

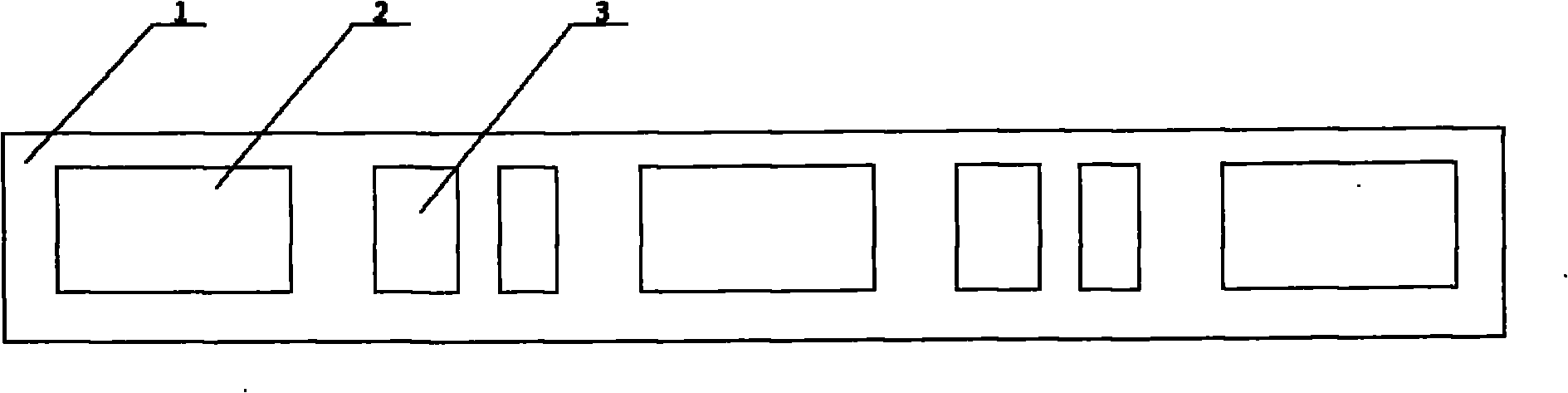

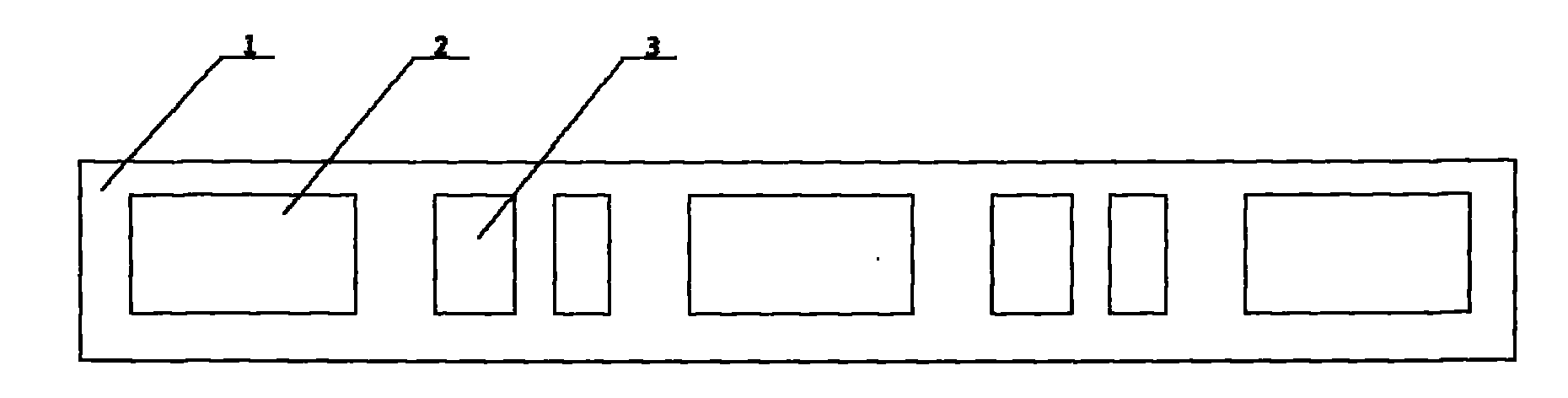

[0015] see figure 1 , a mixed-type LED backlight source, including an LED light bar 1 and a main LED2, the number of the main LED2 is at least one, and is uniformly arranged on the LED light bar 1, the special feature of the present invention is that the main LED2 is provided with At least one sub-LED3, and the color gamut of the sub-LED3 is the same as that of the main LED2, the sub-LED3 has at least one type, and the power of the sub-LED3 is smaller than that of the main LED2.

[0016] Preferably, there are one to five types of sub-LED3, and more preferably, there are two types of sub-LED3.

[0017] Preferably, the auxiliary LEDs 3 arranged between the main LEDs 2 are evenly arranged along the LED light bar 1 , and each main LED 2 and auxiliary LED 3 are respectively equipped with an independent power supply.

[0018] When in use, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com