Solar cell, solar cell string and lamination tile photovoltaic module

A technology for solar cells and photovoltaic modules, applied in photovoltaic power generation, electrical components, circuits, etc., can solve problems such as the reduction of output power of shingled photovoltaic modules, and achieve the effect of avoiding hot spot effects and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

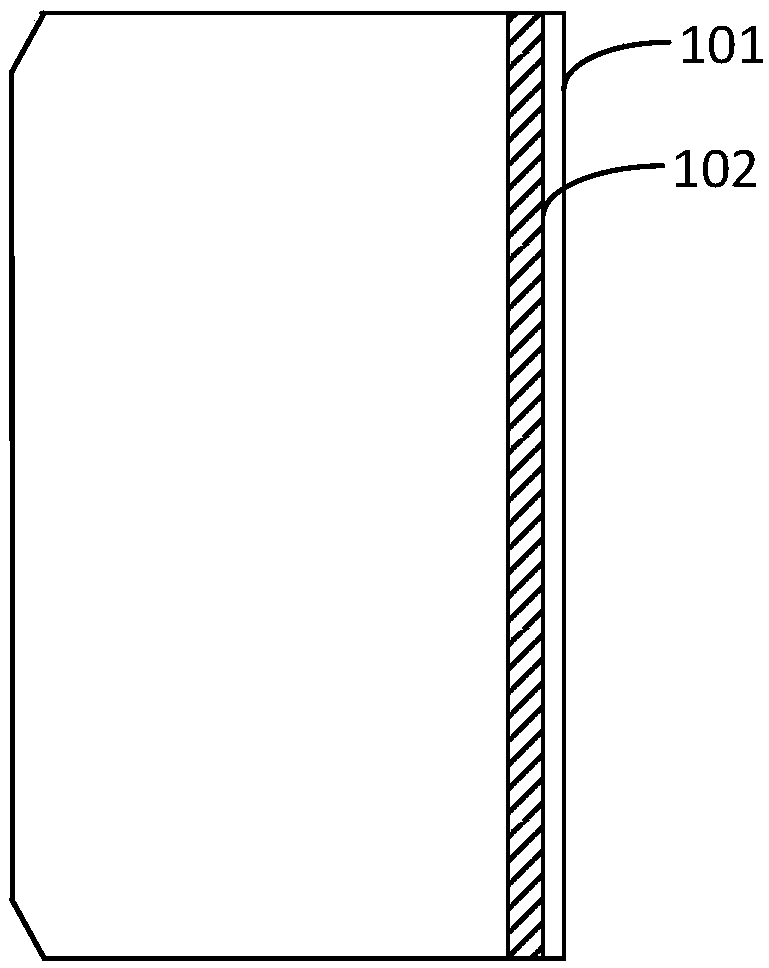

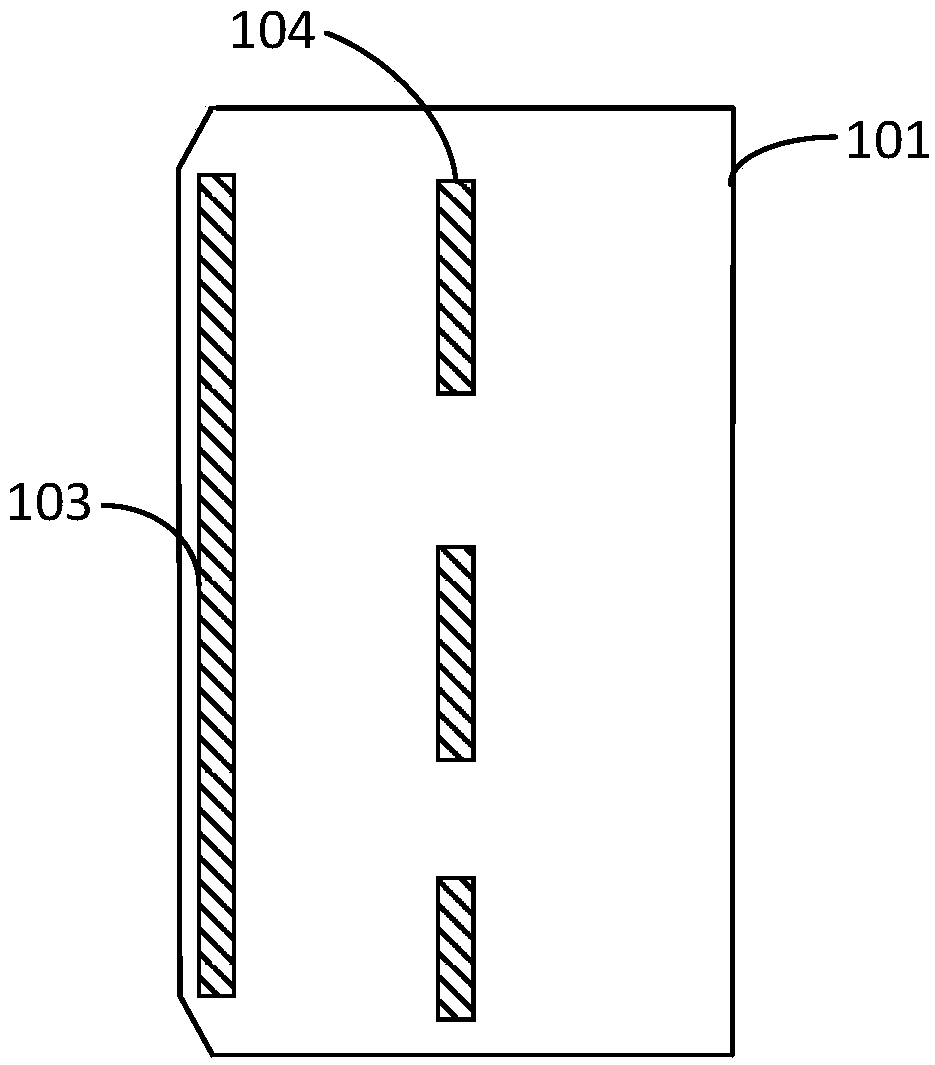

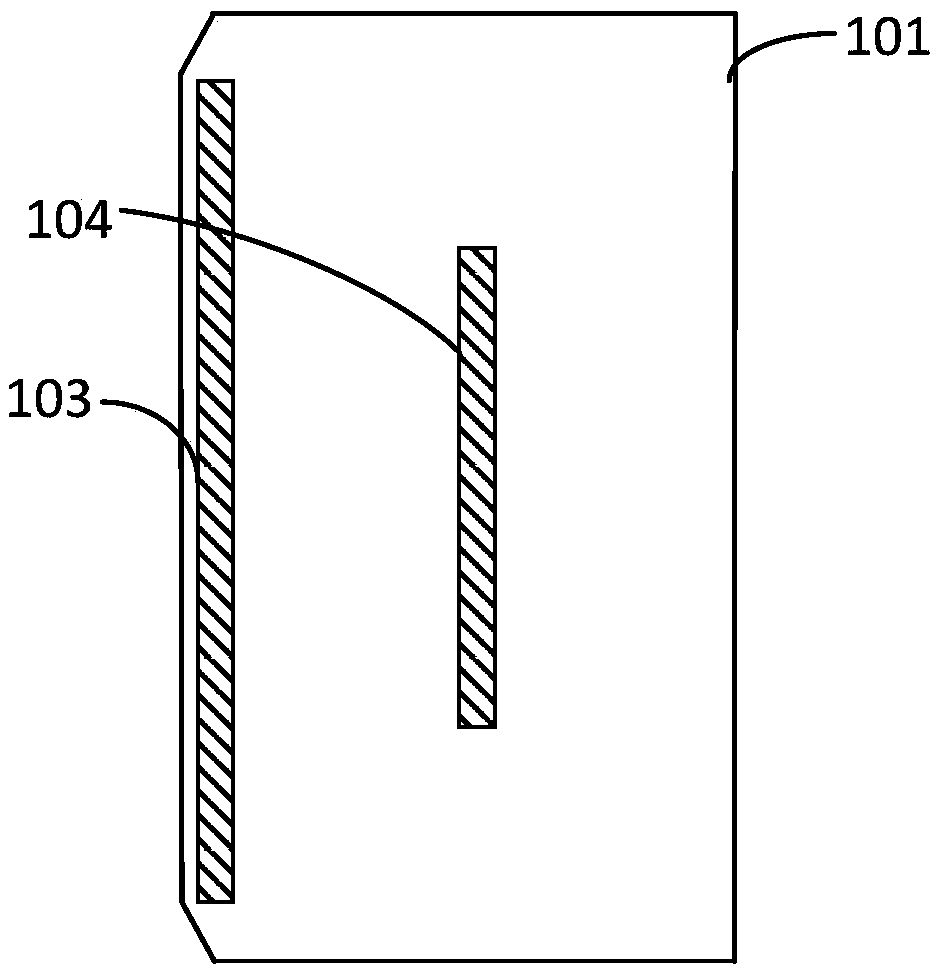

[0025] Please refer to Figure 1 to Figure 3 , the front side of the solar cell 101 is provided with a front busbar 102, and the back side of the solar cell 101 is provided with a back busbar 103, and the front side busbar 102 and the back side busbar 103 are respectively located in the solar cell 101 on both sides. The back side of the solar cell 101 is further provided with an auxiliary grid line 104 parallel to the rear main grid line 103 .

[0026] In this embodiment, the front busbar 102 is provided on the front side of the solar cell 101 , and the back busbar 103 is provided on the back side. The distance between the front busbar 102 and one edge of the solar cell 101 is less than or equal to 1 mm, and the distance between the back busbar 103 and the other edge of the solar cell 101 is less than or equal to 1 mm. The front side of the solar cell 101 is also provided with front fine grid lines (not shown in the drawings), and the back side is also provided with rear fin...

Embodiment 2

[0032] Please refer to Figure 4 to Figure 5 , a solar cell string, including: a plurality of solar cells 101 according to Embodiment 1 of the present invention, and the solar cells 101 are connected in a shingled shape, wherein, the front busbar 102 of any solar cell 101 and its adjacent The rear busbars 103 of the solar cells 101 are overlapped.

[0033] The back of the solar cells in the solar cell string in this embodiment is provided with additional grid lines 104. When the solar cell strings are connected into shingled photovoltaic modules, the current can bypass the solar cells through the additional grid lines 104 to avoid hot spots. Effect, will not lead to the failure of the entire battery string, so that the output power of the photovoltaic module will not be significantly reduced, and there is no need to connect bypass diodes, which can save costs.

[0034] Please refer to Figure 6 , Shingled photovoltaic module, including: a plurality of solar cells as describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com