Method for producing core-pulling and resetting mechanism of injection mould

A technology of injection mold and reset mechanism, which is applied in the field of mold-opening core-pulling and mold-clamping reset mechanism, can solve the problems of high core-pulling slider, large volume, large slope of top locking surface, instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

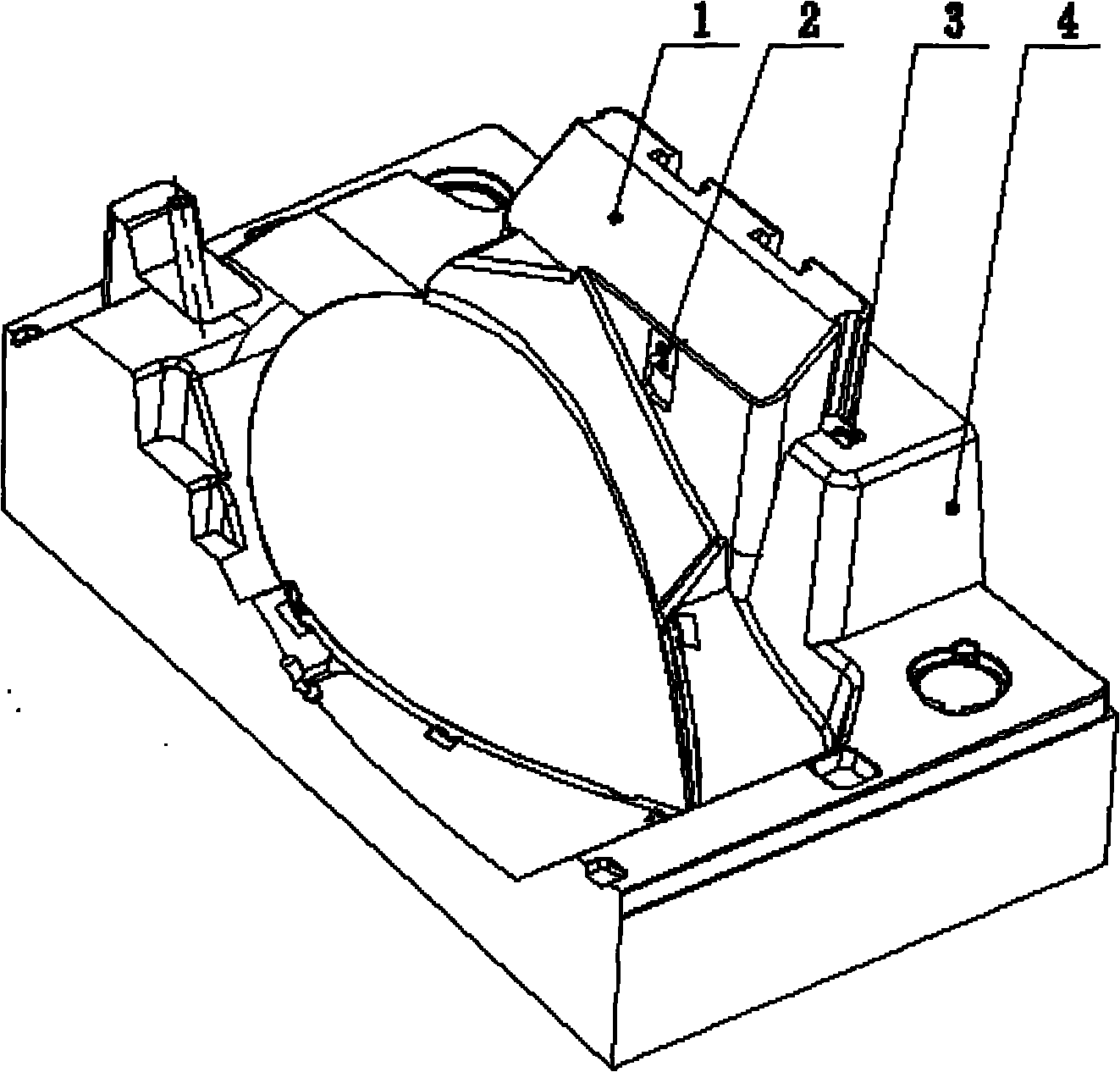

[0015] Depend on figure 1 Known, it is the core-pulling and resetting mechanism of the injection mold of the present embodiment, which is composed of a fixed mold 4, a spring 5, an oil cylinder 6 and a movable mold 10.

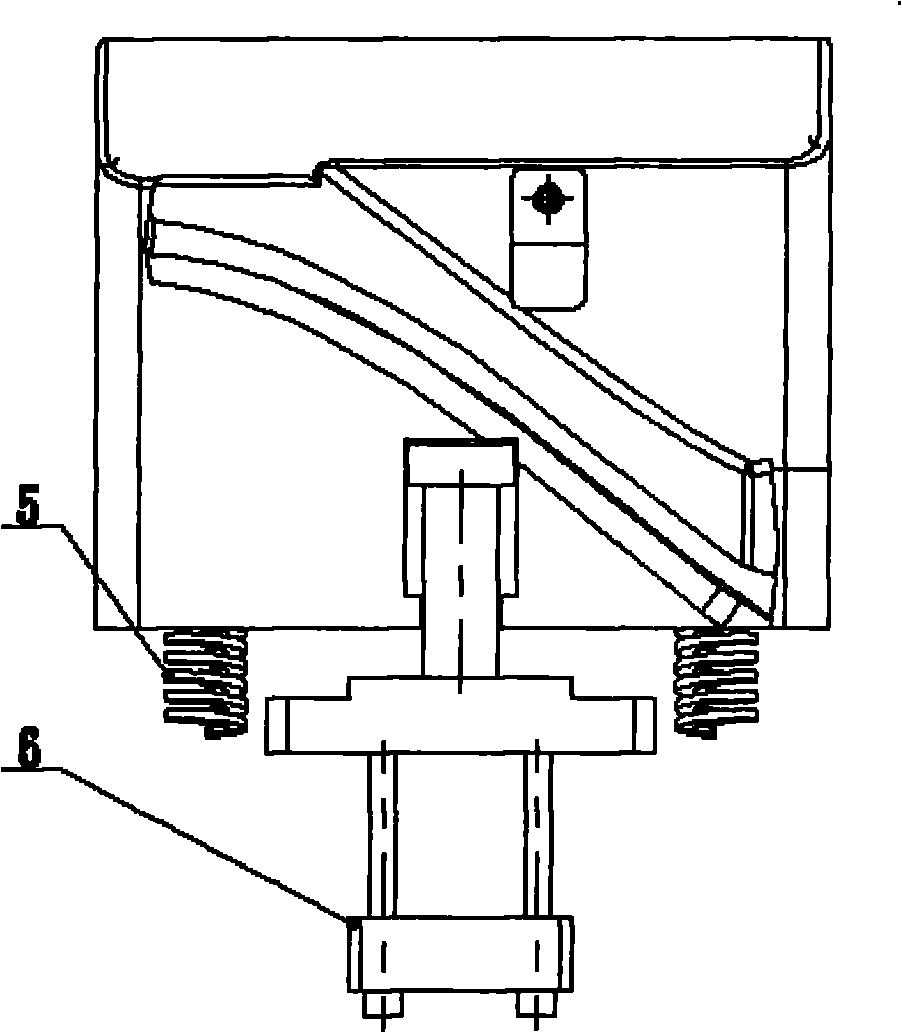

[0016] Depend on figure 2 It is a left view of the present embodiment, a chute 7 is opened on the left side of the fixed mold 4, and the core-pulling slider 1 can slide up and down in the chute 7.

[0017] Depend on image 3 It is a schematic diagram of the structure of the fixed mold, and the fixed mold 4 has a core-pulling slider 1, a buckle 2 and a limit block 3.

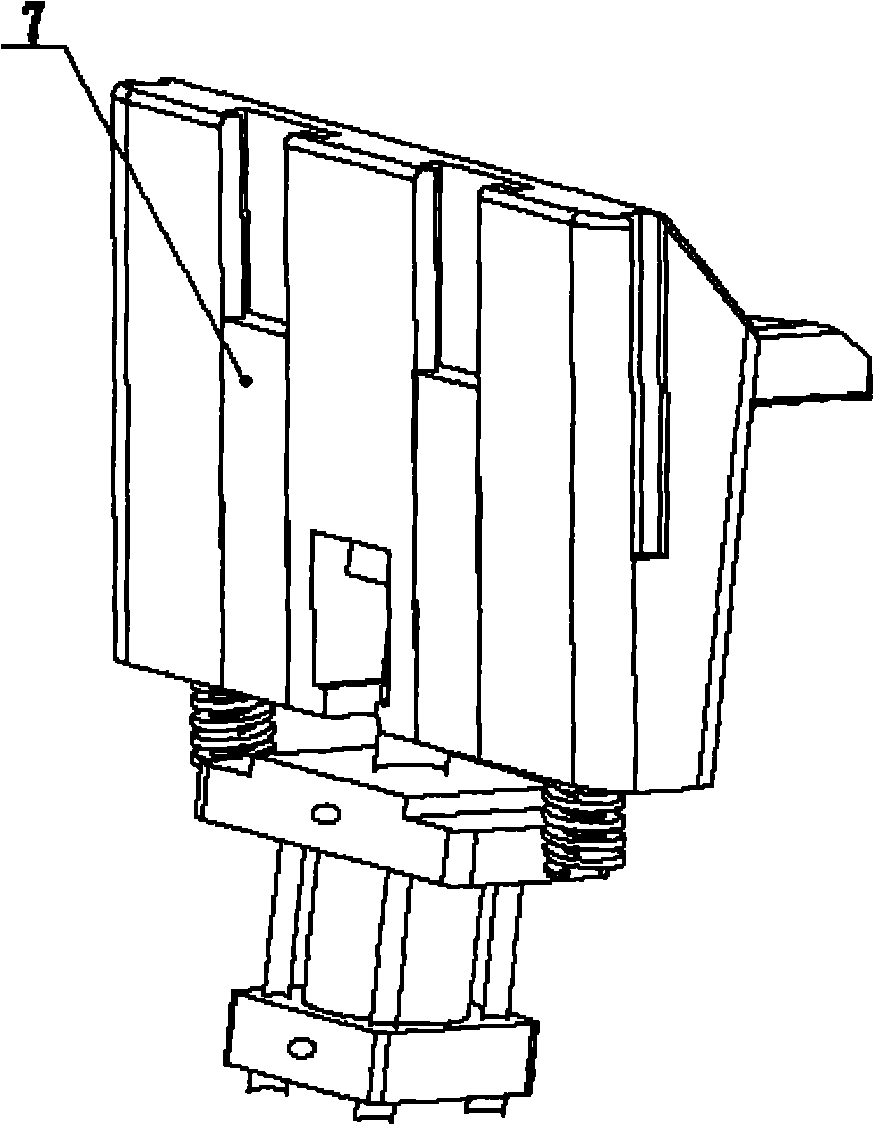

[0018] Depend on Figure 4 It is a schematic diagram of the structure of the movable mold, and the movable mold 10 has a positioning block 8 and a locking block 9.

[0019] When the movable and fixed molds are closed, the buckle 2 and the positioning block 8 are buckled together, the spring 5 is forced to shrink, and the locking block 9 is pressed tightly on the top slope of the core-pulling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com