Multi-lead-screw synchronous motor lifting rod

A lifting rod and lead screw drive technology, applied in the direction of lifting devices, etc., can solve the problems of increasing motor power consumption, large friction area, easy wear of nuts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

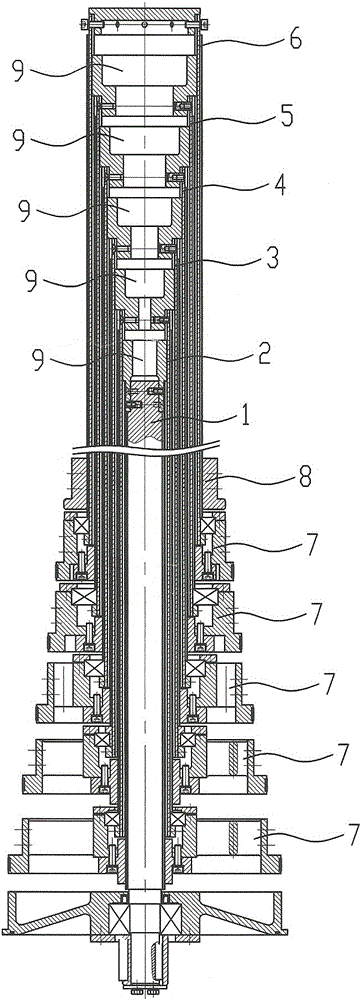

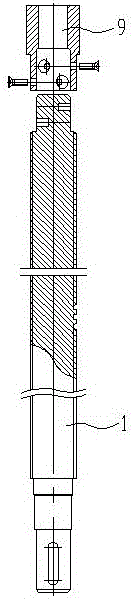

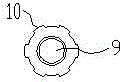

[0018] see figure 1 - Figure 9 , the multi-screw synchronous electric lifting rod of the present invention has a tube body (not shown in the figure) and a tube body screw drive device, the screw drive device includes a plurality of round tube screw screws 1, 2, 3, 4 , 5, 6, the innermost round tube screw is the bottom screw 1, the outermost round tube screw is the top tube screw 6, and the rest of the round tube screw is the inner tube screw 2, 3 , 4, 5, the lower ends of the bottom screw 1 and the inner tube screw 2, 3, 4, 5 are respectively connected with an annular lower sleeve 7, and the lower end of the top tube screw 6 is engaged with a nut 8, The upper ends of the bottom screw 1 and the inner tube screw 2, 3, 4, 5 are connected with an annular upper sleeve 9, and the outer peripheral wall of the annular upper sleeve 9 has a guide key 10 along the axial direction; The inner wall of the inner tube screw 2 , 3 , 4 , 5 and the jack screw 6 has an axial guide groove 11 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com