Technology for preparing natural gas through self-heating catalytic gasification of fire coal, and system thereof

A catalytic gasification and self-heating technology, applied in the direction of fuel, petroleum industry, gas fuel, etc., can solve problems such as poor fluidization state, complicated process flow, and high energy consumption of the process, and achieve industrial scale-up is simple and easy , good technical economy and high system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

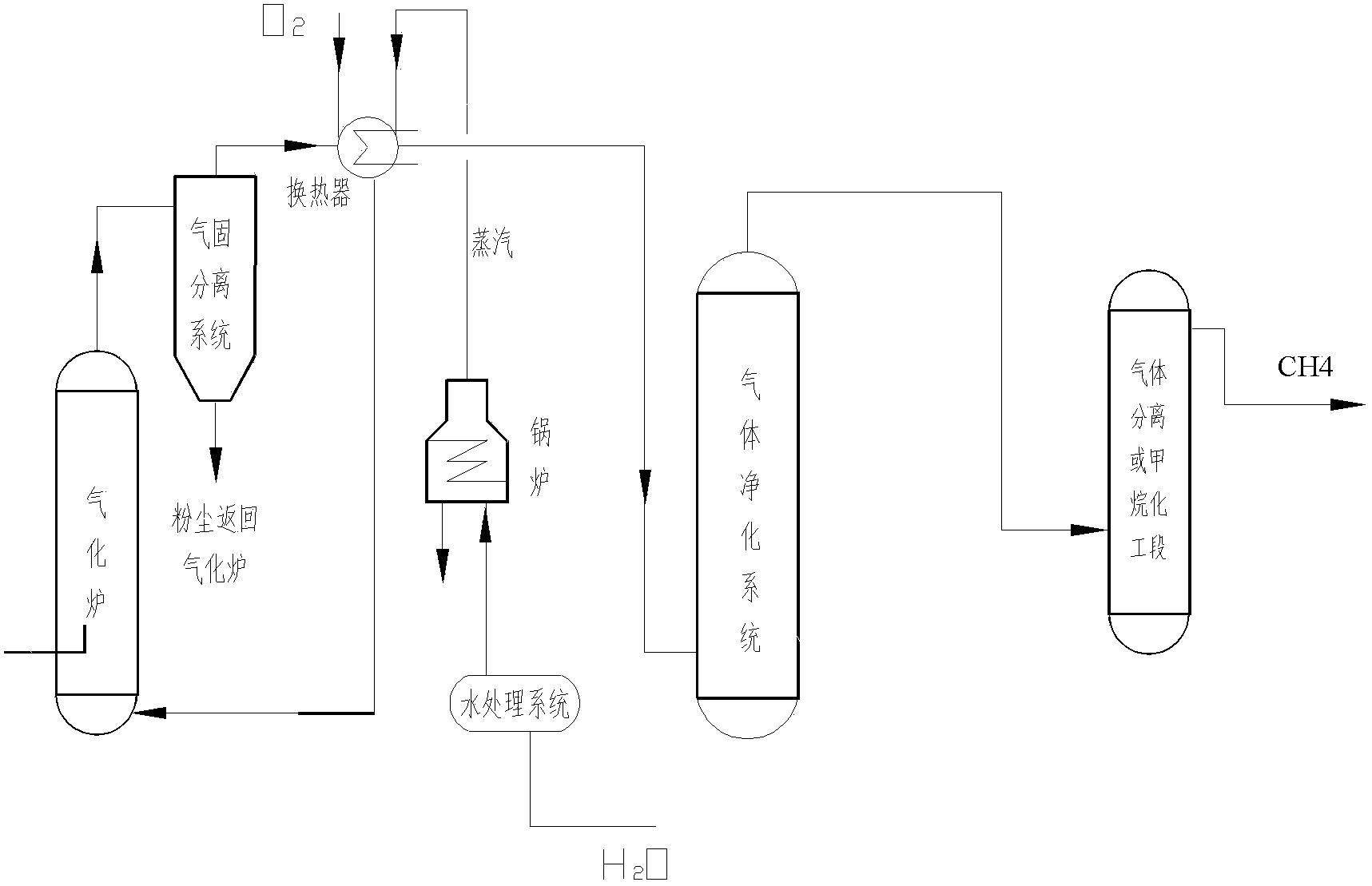

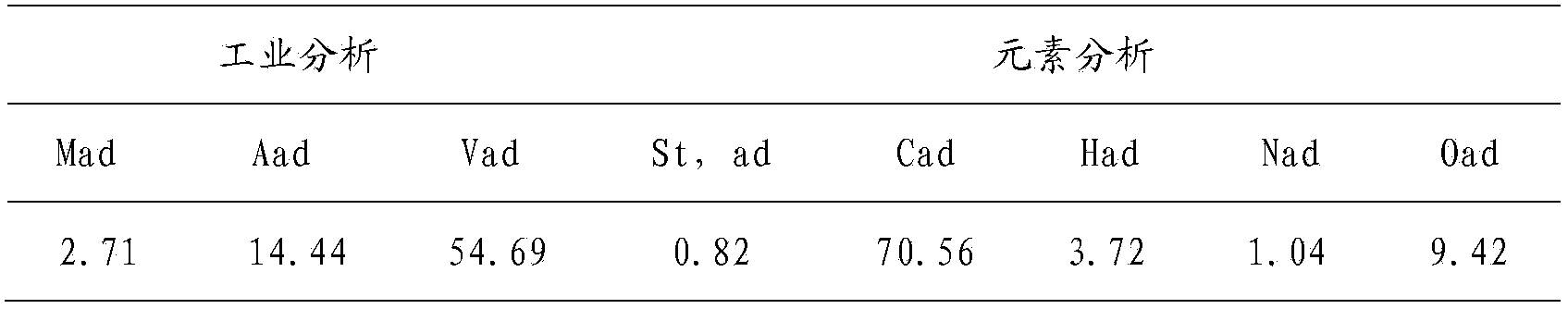

[0065] according to figure 1 and figure 2 The embodiment in the assembly is used for the equipment of the process of producing natural gas through coal catalytic gasification of coal self-heating according to the present invention.

[0066] The process as described in the specific embodiment section is used for coal-fired self-heating coal catalytic gasification to produce natural gas. Wherein, the temperature of the gasifying agent is 500°C.

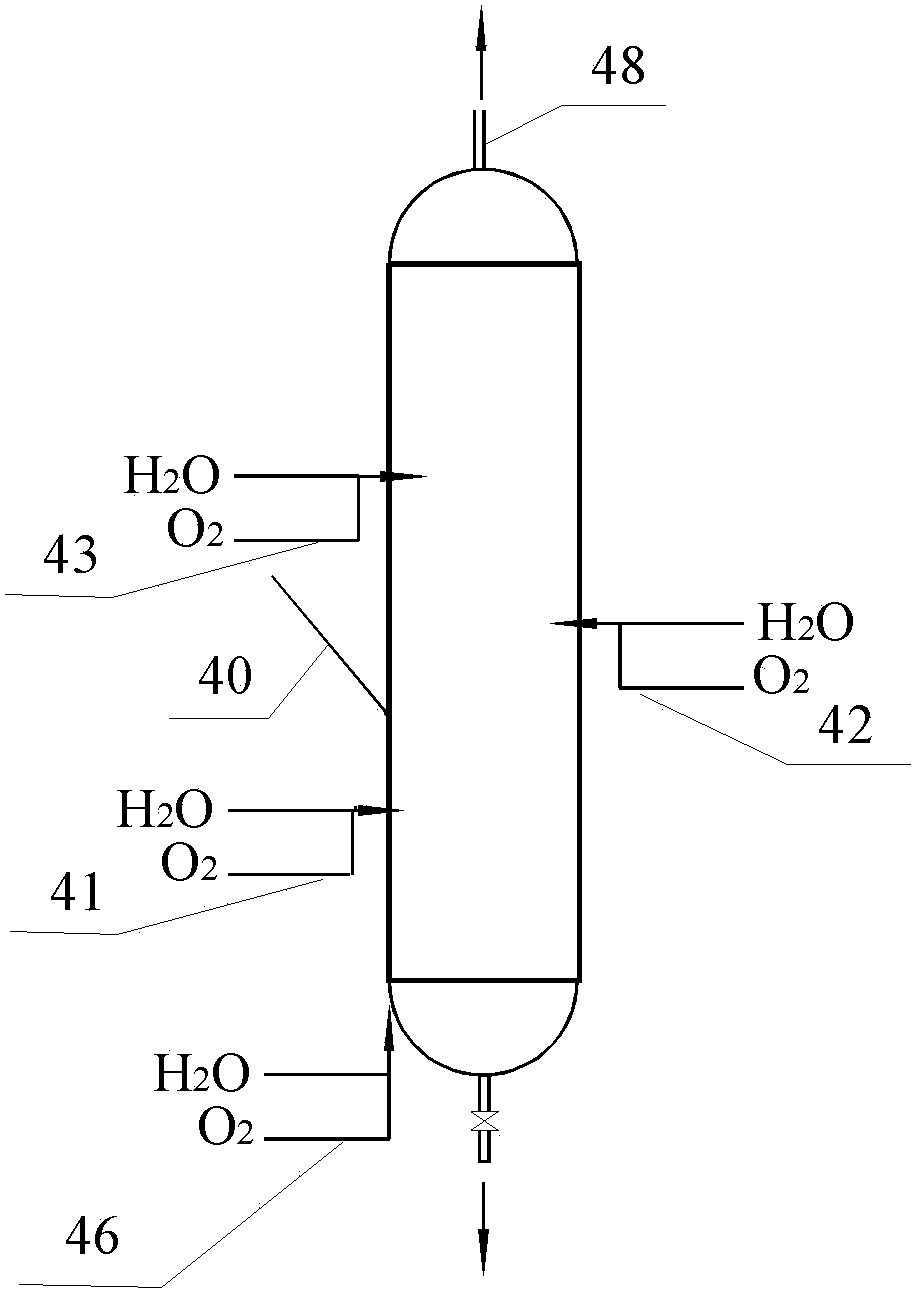

[0067] In the gasification agent introduced into the gasification device 20, the oxygen concentration of the gasification agent entering the gasification device 20 from the distribution plate is 5mol%, and the gasification agent entering the gasification device 20 from the bed gas distribution device is The oxygen concentration was 10 mol%.

[0068] In the above equipment for coal-fired self-heating coal catalytic gasification to produce natural gas, the specific structure for supplying gasification agent in a dispersed manner is as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com