Liquid working medium temperature change self circulation power generation device and power generation method

A technology of working fluid temperature and power generation device, which is applied in hydropower generation, renewable energy power generation, engine components, etc., can solve the problems of high cost, waste of energy, and small proportion, and achieve the effect of low cost and high power generation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

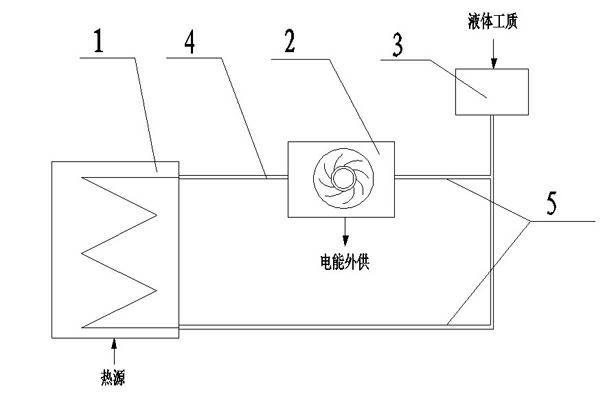

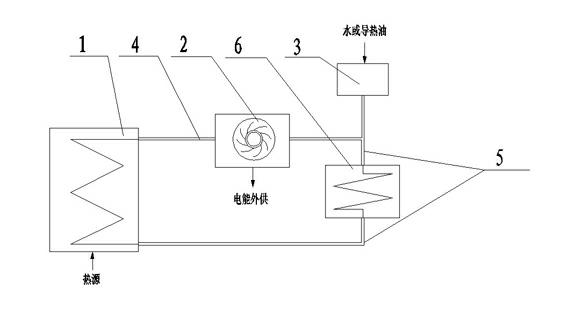

[0022] Embodiment one, with reference to the attached figure 2 , the present embodiment is a self-circulating heating furnace applying the present invention to increase the power generation function, and extending it into a power generating heating furnace.

[0023] The radiator 6 is installed on the connecting pipe 5 at the outlet of the hydro-generator 2. After the heated liquid working medium passes through the hydro-generator 2 to generate electricity, it enters the radiator 6 to cool down, and the radiator transfers the heat of the liquid working medium to the required heat. For users, the liquid working fluid after the temperature is lowered automatically flows back to the lower inlet of the liquid working medium heater 1, forming a loop of natural circulation of the liquid working medium.

[0024] The radiator 6 of the heating furnace for power generation can be one or multiple parallel or series installations; the hydroelectric generator can also be installed at the o...

Embodiment 2

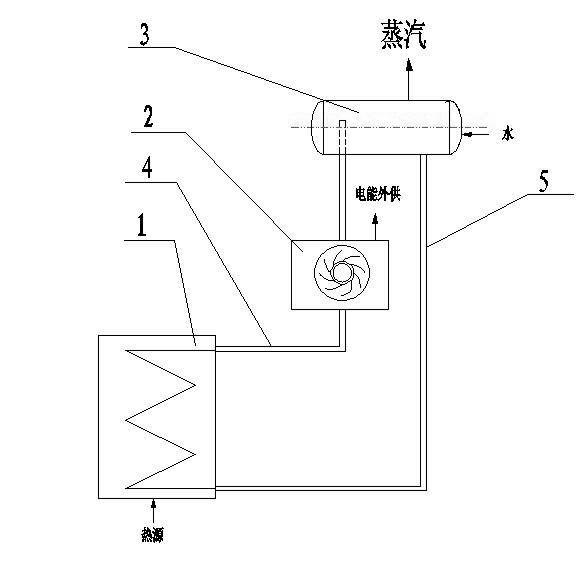

[0025] Embodiment two, referring to the attached image 3 , the present embodiment applies the present invention to a steam boiler to increase the power generation function, and is extended to a steam boiler for power generation.

[0026] The liquid working medium high-level storage tank 3 is a steam drum, and the pipeline 4 is a steam rising pipe connected to the steam drum, extending to 1 / 2 of the liquid level of the steam drum, and the connecting pipe 5 is connected to the bottom outlet of the steam drum and the heater inlet. 4 is equipped with a hydroelectric generator, and the liquid working medium is water; the water is heated in the liquid working medium heater 1, and the temperature increases, and the volume increases to form a steam-water mixture. The outlet is discharged along the pipeline 4 and passes through the hydro-generator 2 to push the hydro-generator to do work. The electric energy is supplied externally. After decompression, the steam-water mixture enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com