Energetic room-temperature curing agent based on hydroxyl-terminated polybutadiene bonding system and solidified body thereof and preparation method thereof

A technology of hydroxyl-terminated polybutadiene and room temperature curing agent, which is applied in chemical instruments and methods, preparation of organic compounds, adhesives, etc., can solve problems such as high curing molding temperature and unsatisfactory properties of cured products, and achieve the goal of curing products containing Performance improvement, suitable for large-scale industrial production, and wide environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for preparing an energetic room-temperature curing agent based on a hydroxyl-terminated polybutadiene bonding system, that is, a method for preparing 5-nitrobenzene-1,3-dinitrile oxide, comprising the following steps:

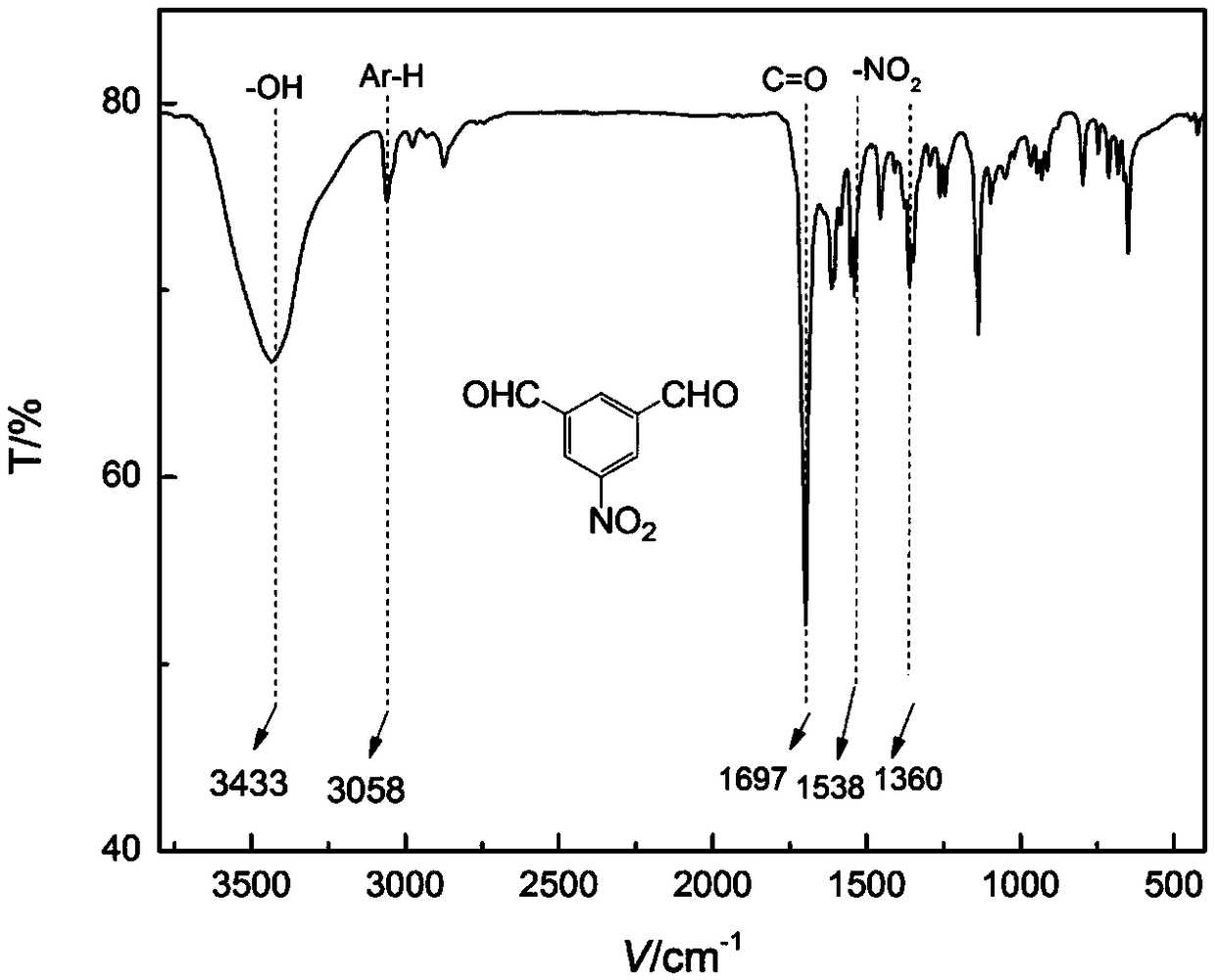

[0046] a. Nitration: Add 13.4g of 1,3-phthalaldehyde and 12.2g of acetyl nitrate into a 250ml three-neck flask under ice bath temperature, mix well and carry out nitration reaction at 40°C for 100 minutes; wait for the reaction to complete Finally, the reaction product is poured into ice water while it is hot (the volume consumption of ice water can be 1 to 4 times the volume of the material after the reaction, and the ice water is a mixture of ice and water with a temperature of 0 to 4 ° C, the same below), and the yellow color is immediately precipitated. Suction filter the solid, wash the solid with ice water, and dry to obtain a pale yellow 5-nitrobenzene-1,3-dicarbaldehyde solid for use;

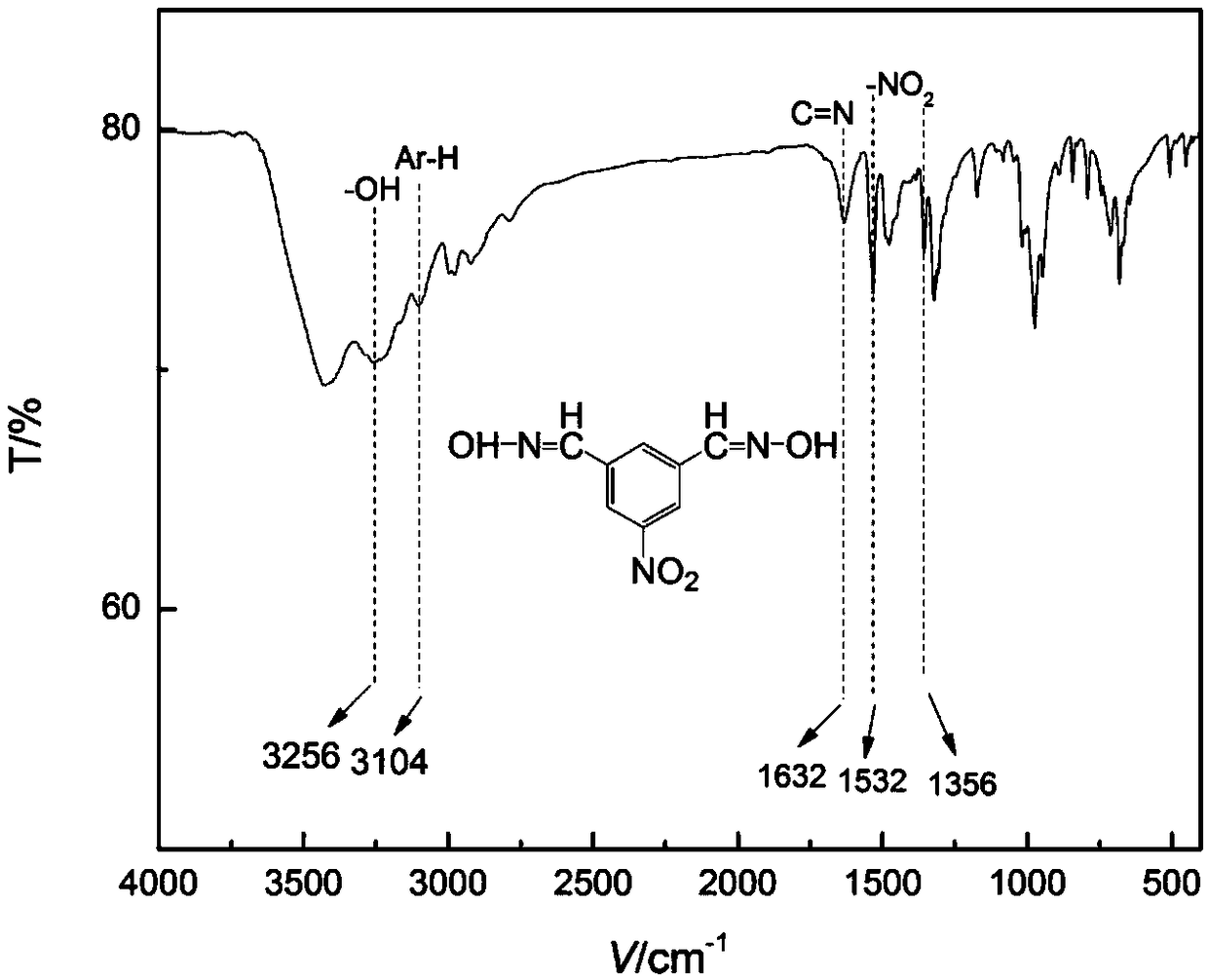

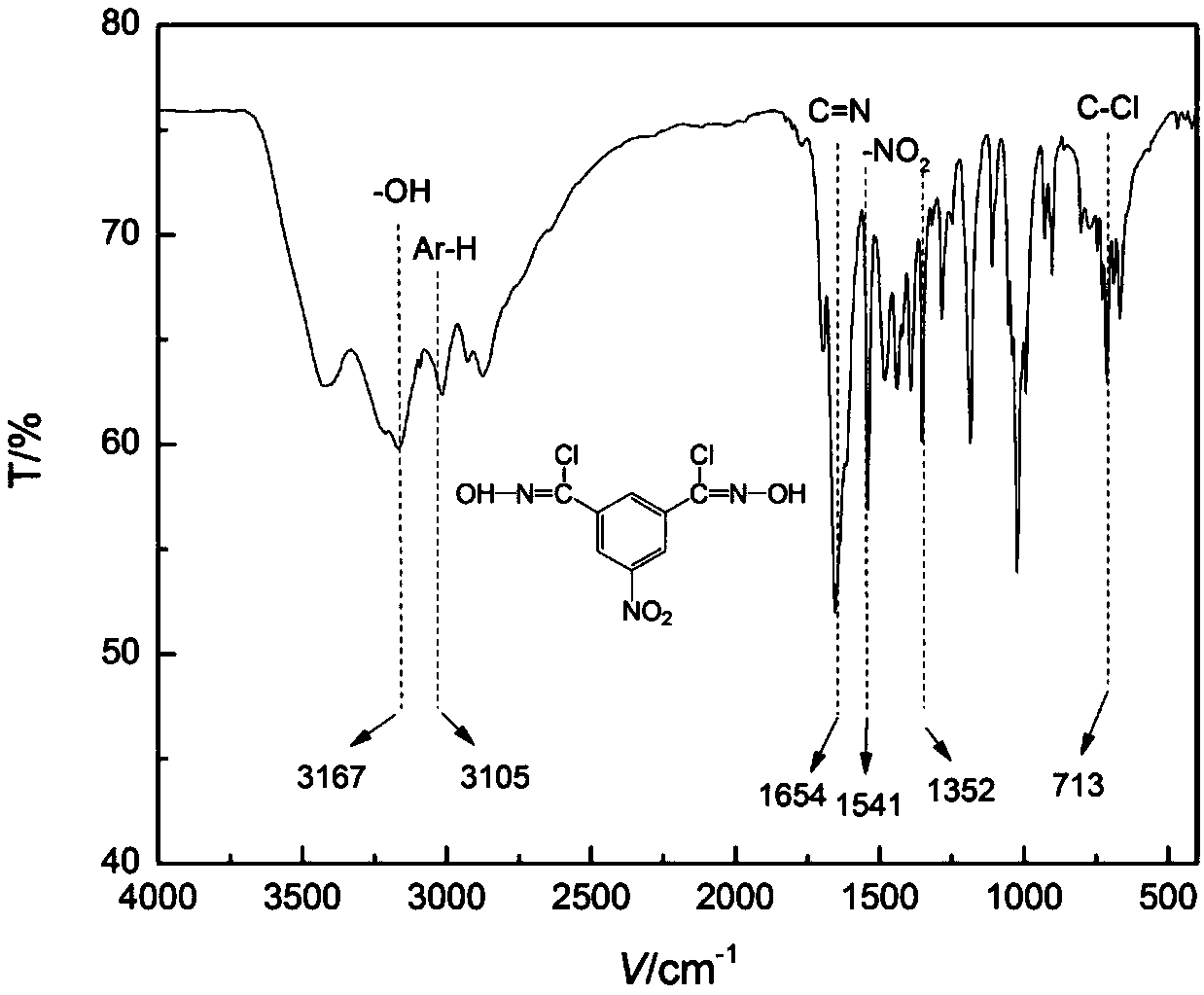

[0047] b. Oximation: Add 17.9g of 5-nitrobenzene-1,...

Embodiment 2

[0055] A method for preparing an energetic room-temperature curing agent based on a hydroxyl-terminated polybutadiene bonding system, that is, a method for preparing 5-nitrobenzene-1,3-dinitrile oxide, comprising the following steps:

[0056] a. Nitration: Add 13.4g of 1,3-benzenedicarbaldehyde to a 250ml three-necked flask, dissolve it in 44mL of concentrated sulfuric acid, and add the mixed acid dropwise (the mixed acid is 13mL of concentrated sulfuric acid and 27mL of concentrated nitric acid) mixed acid) mixed uniformly and then carried out nitration reaction at 50°C for 80 minutes; after the reaction was completed, pour the reaction product into ice water while hot (the volume of ice water can be 1 to 4 times the volume of the material after the reaction, and the ice water can be A yellow solid was precipitated immediately in a mixture of ice and water at a temperature of 0-4°C, the same below), and was filtered with suction, washed with ice water, and dried to obtain a li...

Embodiment 3

[0065] A method for preparing an energetic room-temperature curing agent based on a hydroxyl-terminated polybutadiene bonding system, that is, a method for preparing 5-nitrobenzene-1,3-dinitrile oxide, comprising the following steps:

[0066] a. Nitration: Add 13.4g of 1,3-benzenedicarbaldehyde to a 250ml three-necked flask, dissolve it in 44mL of concentrated sulfuric acid, and add the mixed acid dropwise (the mixed acid is 13mL of concentrated sulfuric acid and 27mL of concentrated nitric acid) mixed acid) mixed uniformly and then carried out nitration reaction at 50°C for 80 minutes; after the reaction was completed, pour the reaction product into ice water while hot (the volume of ice water can be 1 to 4 times the volume of the material after the reaction, and the ice water can be A yellow solid was precipitated immediately in a mixture of ice and water at a temperature of 0-4°C, the same below), and was filtered with suction, washed with ice water, and dried to obtain a li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com