A device with a magnetic domain wall adjustable manganese oxide film and a magnetic domain wall adjustment method

A manganese oxide and magnetic domain wall technology, which is applied to devices with a magnetic domain wall regulated manganese oxide film and the field of magnetic domain wall regulation, can solve the problems of increasing, a large amount of waste heat, and the inability to reduce the critical current density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

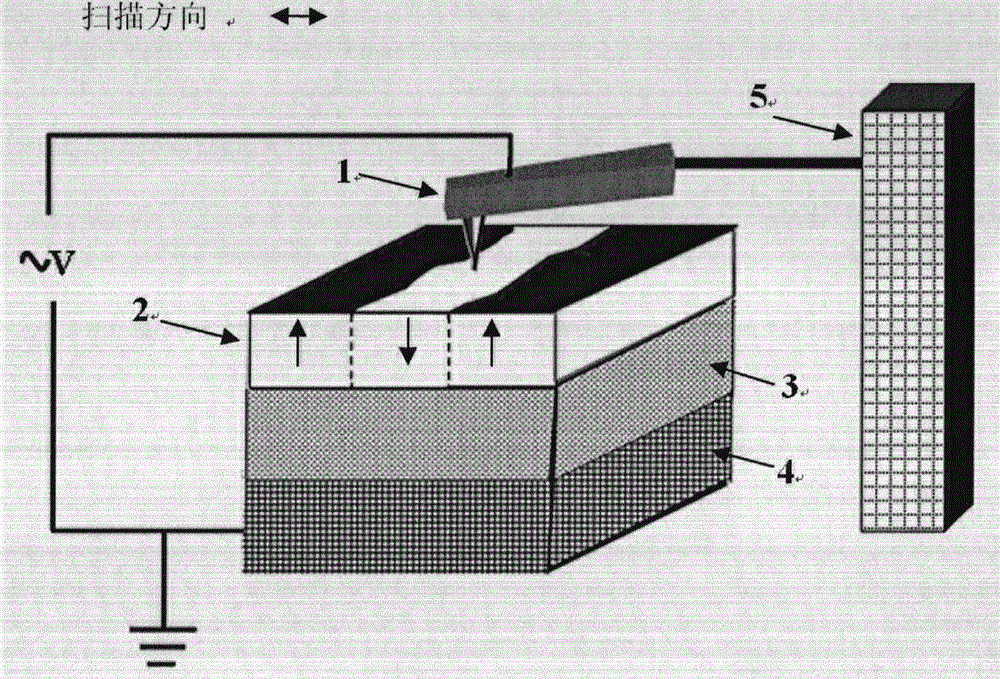

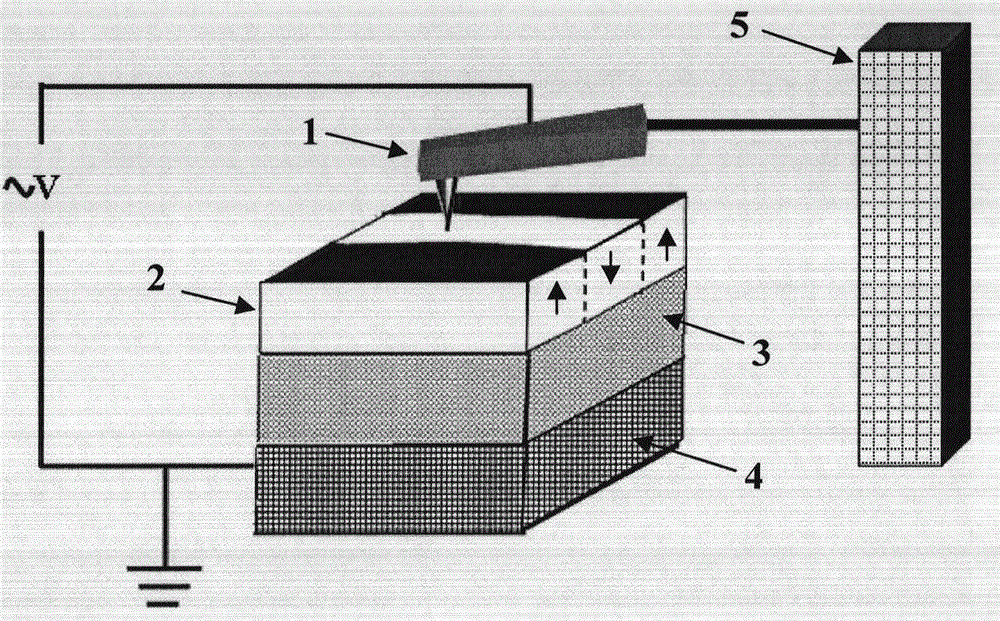

Method used

Image

Examples

Embodiment 1

[0034] Using pulsed laser deposition technology, the optically polished LaAlO 3 (001) Preparation of epitaxially grown La on a single crystal substrate 0.67 Sr 0.33 MnO 3 film. During the preparation process, the substrate temperature was 780°C, the oxygen pressure was 50 Pa, the laser energy was 170 mJ, the frequency was 3 Hz, and the distance between the substrate and the target was 4.1 cm. The coating time is 15 minutes. After preparation, the film is annealed in situ at 700℃, and the oxygen pressure during annealing is 4×10 4 Pa, annealing time is 10 minutes, and then the temperature is cooled naturally. Income La 0.67 Sr 0.33 MnO 3 The thickness is about 100 nm. Label the sample as LSMO / LAO. Take the LSMO / LAO sample out and place it on a metal conductive bottom plate (such as a copper bottom plate), and the sample is in close contact with the conductive bottom plate to form a manganese oxide core unit with adjustable magnetic domain walls.

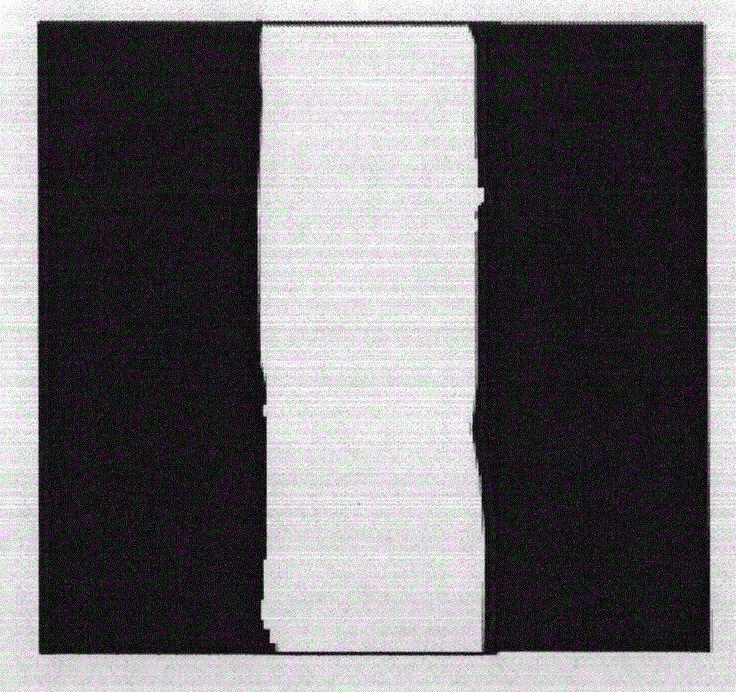

[0035] In the La 0.67 Sr 0.33 ...

Embodiment 2

[0043] Using the same method in Example 1 to prepare La (1-x) Ba x MnO 3 (x=0.2, 0.3), and using the same method for magnetic domain control, the same magnetic domain structure as in Example 1 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com