Metal shaping method based on local constrained electrochemistry

An electrochemical processing and localized technology, applied in electrochemical processing equipment, metal processing equipment, circuits, etc., can solve the problems of low processing accuracy, large shape restrictions, easy annealing, etc., and achieve a large processing size range, no The effect of material hardness limitation and precision limitation is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

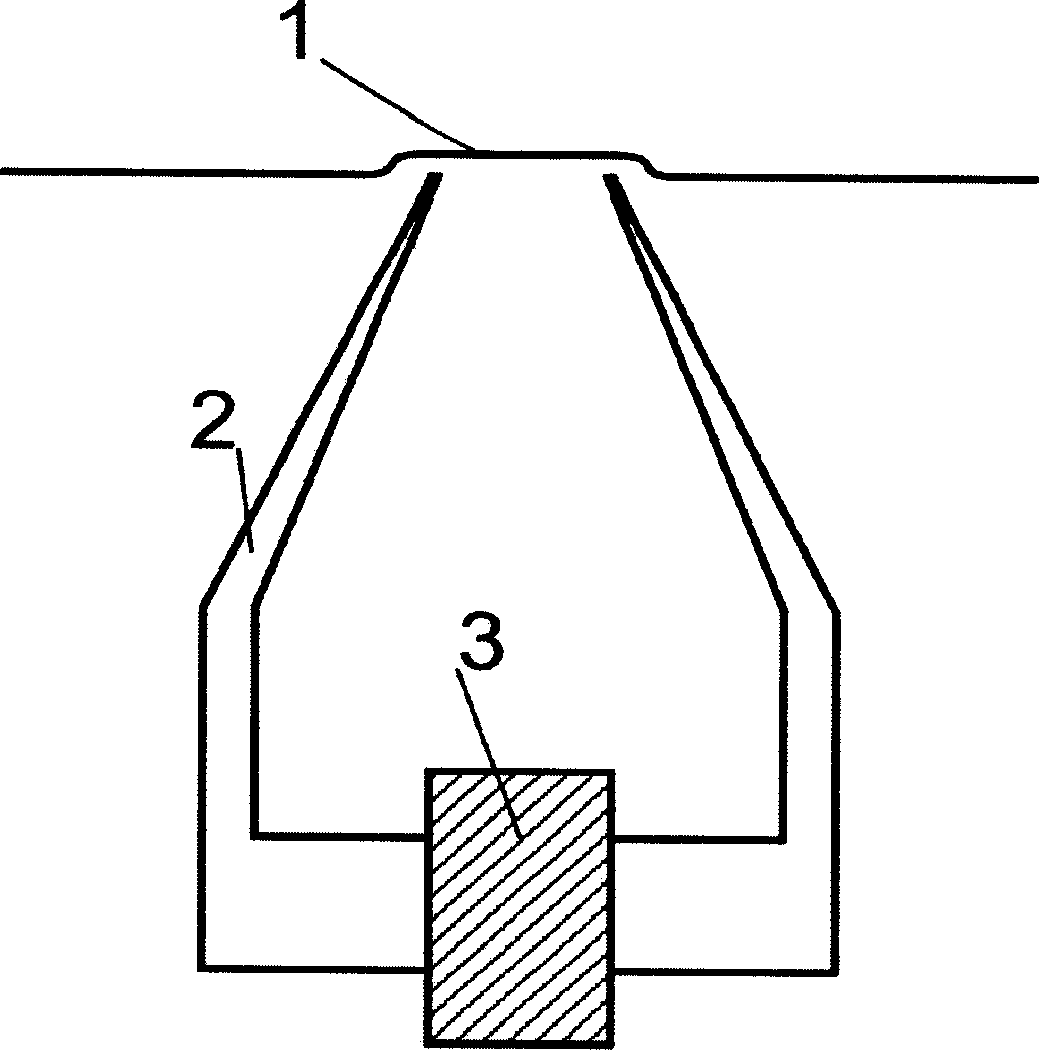

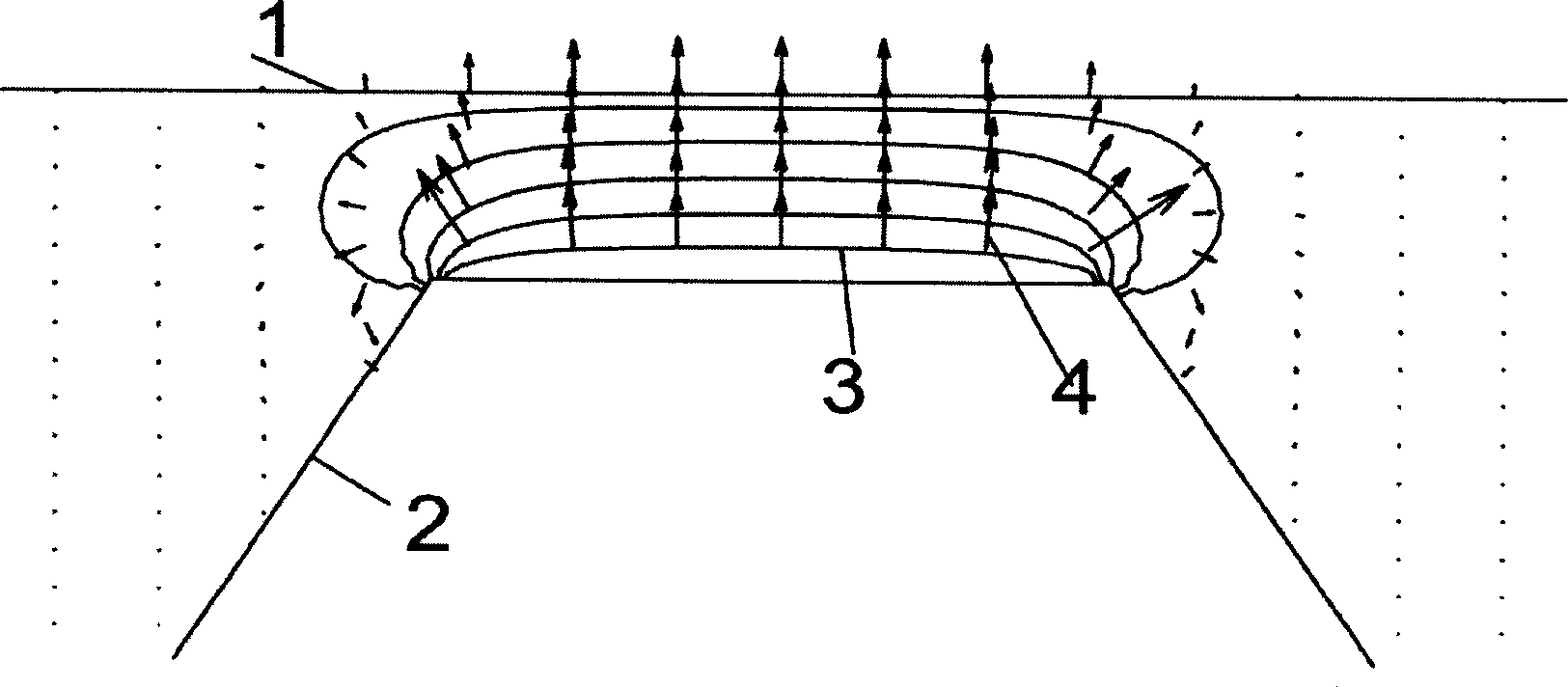

[0010] In the electrolytic cell for the material to be processed, the metal material is the anode, and the cathode is placed in a semi-closed conical confinement tube made of insulating material. The tip opening of the confinement tube faces and is close to the anode, such as figure 1 . Under the appropriate voltage, the potential of the nozzle is slightly higher than the electrolytic potential of the metal material. Due to the resistance of the solution, only the material near the nozzle can lose electrons and enter the electrolyte. And repeat this process to achieve the purpose of processing. In order to take into account the speed, the rough blank can be processed with a large-aperture constrained tube first, and then processed with a small-aperture constrained tube. Conversely, if the processing environment is changed to electroplating, and the workpiece is the cathode, selective surface treatment can be done to improve the finish and corrosion resistance of the parts. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com