A kind of polypropylene physical foam composite board and its manufacturing process

A technology of physical foaming and manufacturing process, which is applied in the field of plastic foaming and compounding, can solve the problems of fast burning speed, insufficient strength and corrosion in case of fire, and achieve the effects of simple production process, slow burning speed and good heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

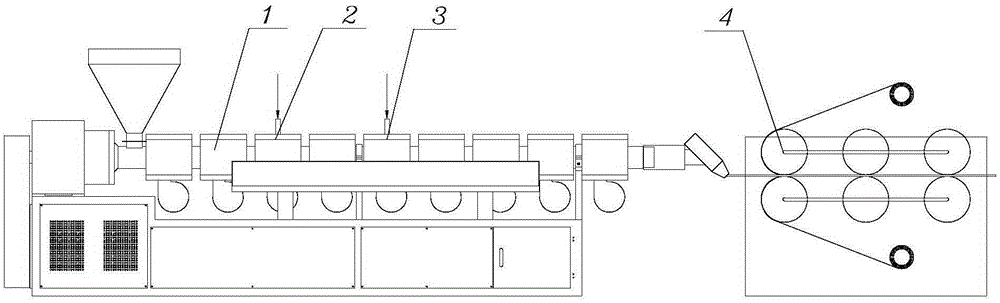

[0030] The manufacturing process of a kind of polypropylene physical foaming composite plate that present embodiment provides, such as figure 1 As shown, the equipment adopts a single-screw extruder 1 with a length-to-diameter ratio of 36:1 and ten stages of heating temperature. , 230°C, 220°C, 208°C; gas injection pressure requirements: inject liquid additives in the third section 2, the pressure is: 10MPa, inject nitrogen in the sixth section 3, the pressure is: 25MPa; The formula is as follows by weight percentage: 93% polypropylene, the model is Yangzi Petrochemical F401, the compatibilizer is 3%, the model is Nanjing Huadu Technology Industry Co., Ltd. HD900P, the nucleating agent is 2%, the model is Nanjing Huadu Technology Industry Co., Ltd. HD101 , No. 15 white oil 2%; the composite fabric on both sides of the foam layer is flannelette.

[0031] With the above-mentioned equipment and setting process, the foaming material is extruded through the mold and directly extru...

Embodiment 2

[0033] The process parameters of this embodiment are the same as those of Example 1, the difference being that the formula of the foamed layer is different, and the formula of the foamed layer is as follows by weight percentage: 90% polypropylene, the model is Yangzi Petrochemical F401, 8% compatibilizer, The model is Nanjing Huadu Technology Industry Co., Ltd. HD900P, nucleating agent 1%, the model is Nanjing Huadu Technology Industry Co., Ltd. HD101, No. 15 white oil 1%; the composite fabric on both sides of the foam layer is fleece.

[0034] Using the above-mentioned equipment and setting process, the foaming material is extruded through the mold and directly extruded onto the roller located on the velvet cloth, and is extruded and shaped by the upper and lower rollers. The foaming degree of the finished product reaches 75%. The 2.5mm thick double suede PP foam composite board has 2-3 times the tensile strength and 1.5-3 times the bending strength of the traditional foam com...

Embodiment 3

[0036] The process parameters of this embodiment are the same as the process parameters of Example 1, the difference is that the formula of the foam layer is different, and the formula of the foam layer is as follows in percentage by weight: polypropylene 96%, the model is Yangzi Petrochemical F401, compatibilizer 2%, The model is Nanjing Huadu Technology Industry Co., Ltd. HD900P, the nucleating agent is 1.2%, the model is Nanjing Huadu Technology Industry Co., Ltd. HD101, No. 15 white oil 0.8%; the composite fabric on both sides of the foam layer is flannelette.

[0037] Using the above-mentioned equipment and setting process, the foaming material is extruded through the mold and directly extruded onto the roller located on the velvet cloth, and is extruded and shaped by the upper and lower rollers. The foaming degree of the finished product reaches 83%. The 5.5mm thick double suede PP foam composite board has 4-5 times the tensile strength and 2.5-4 times the bending strengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com