Emulsified soybean protein feed and production method thereof

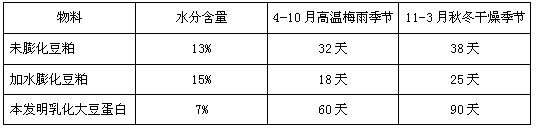

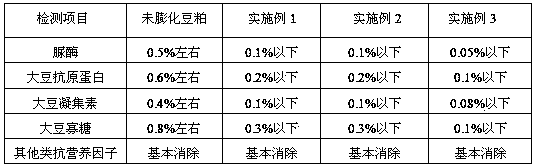

A soybean protein and production method technology, applied in animal feed, animal feed, application, etc., can solve the problems of easy mold and deterioration of feed, unfavorable long-term storage, and short storage time, so as to improve growth rate and reproductive ability, improve Palatability and appetite, effect of improving digestion and absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

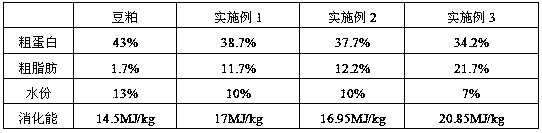

Embodiment 1

[0039] Weigh 100 kg of emulsified soybean oil and 900 kg of soybean meal, send the weighed soybean meal into the mixer, slowly add the emulsified soybean oil and stir for 3 minutes under agitation, then input the prepared mixture into the extruder for expansion, at a temperature of 120°C and 20 kg of pressure for puffing for 12 seconds, and finally the obtained emulsified soybean protein feed is pulverized by a pulverizer, passed through a 10-40 mesh sieve, and packaged.

Embodiment 2

[0041] Weigh 100 kg of emulsified lard and 900 kg of soybean meal, send the weighed soybean meal into the mixer, slowly add emulsified lard and stir for 5 minutes under agitation, then input the prepared mixture into the extruder for expansion, The temperature is 120° C., and the pressure is 20 kg, and it is expanded for 12 seconds. Finally, the obtained emulsified soybean protein feed is pulverized by a pulverizer, passed through a 10-40 mesh sieve, and packaged.

Embodiment 3

[0043] Stir and mix 100 kg of emulsified lard and 100 kg of emulsified soybean oil, weigh 800 kg of soybean meal, send the weighed soybean meal into a mixer, and slowly add the mixed emulsified soybean oil and emulsified lard under agitation and stir for 5 Minutes, then enter the prepared mixture into the extruder for expansion, and expand for 14 seconds at a temperature of 150°C and a pressure of 25 kg. Finally, the obtained emulsified soybean protein feed is crushed by a pulverizer and passed through a 10-40 mesh sieve. Package.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com