Vibratory spiral fluidized horizontal shell-and-tube heat exchanger

A horizontal tube-and-vibration-spiral technology, applied in heat exchanger types, indirect heat exchangers, fixed tubular conduit components, etc., can solve the problems of difficult concentration adjustment operation technology and difficulty in adjusting the range to meet engineering requirements, etc. achieve effective cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

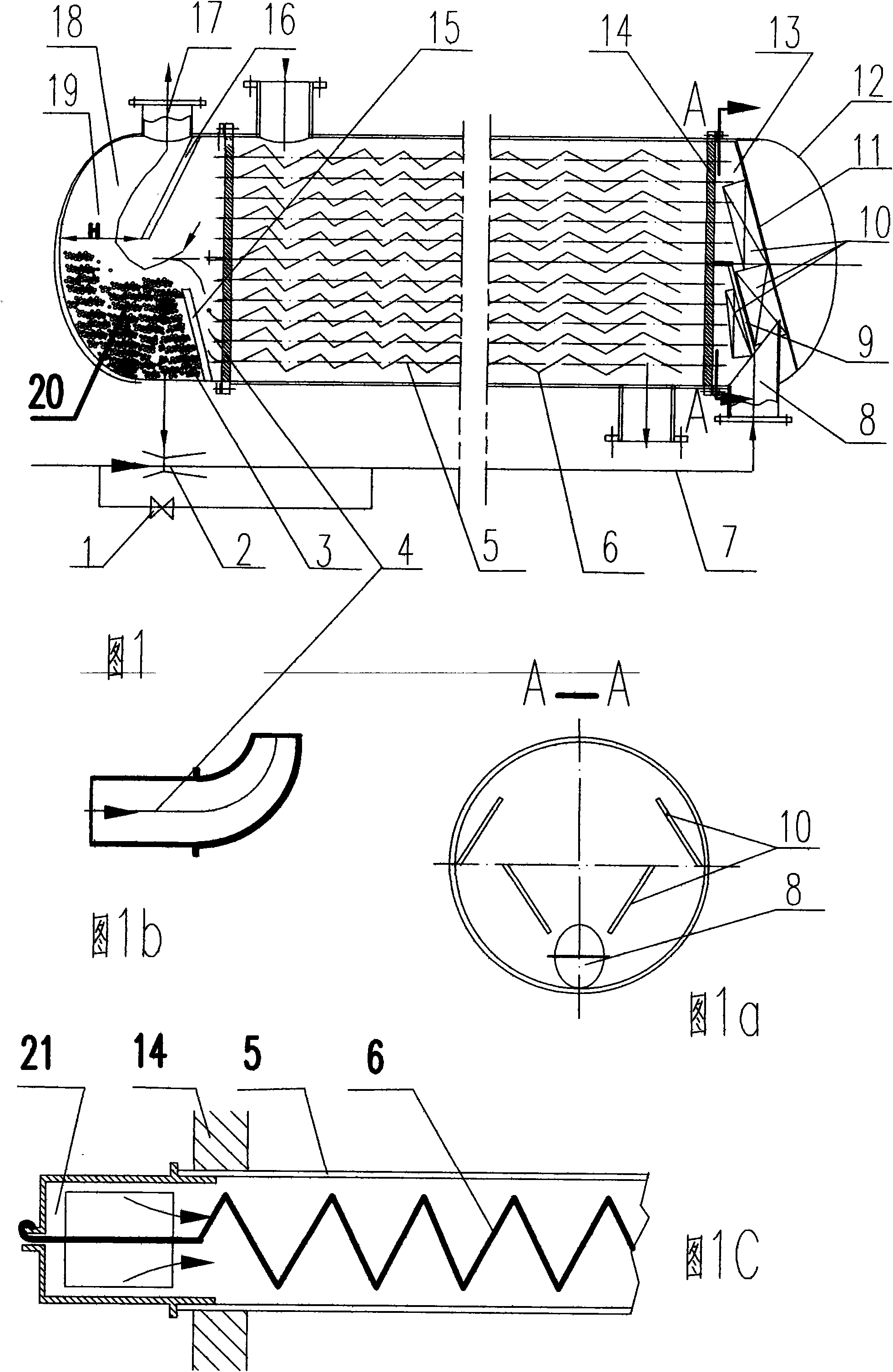

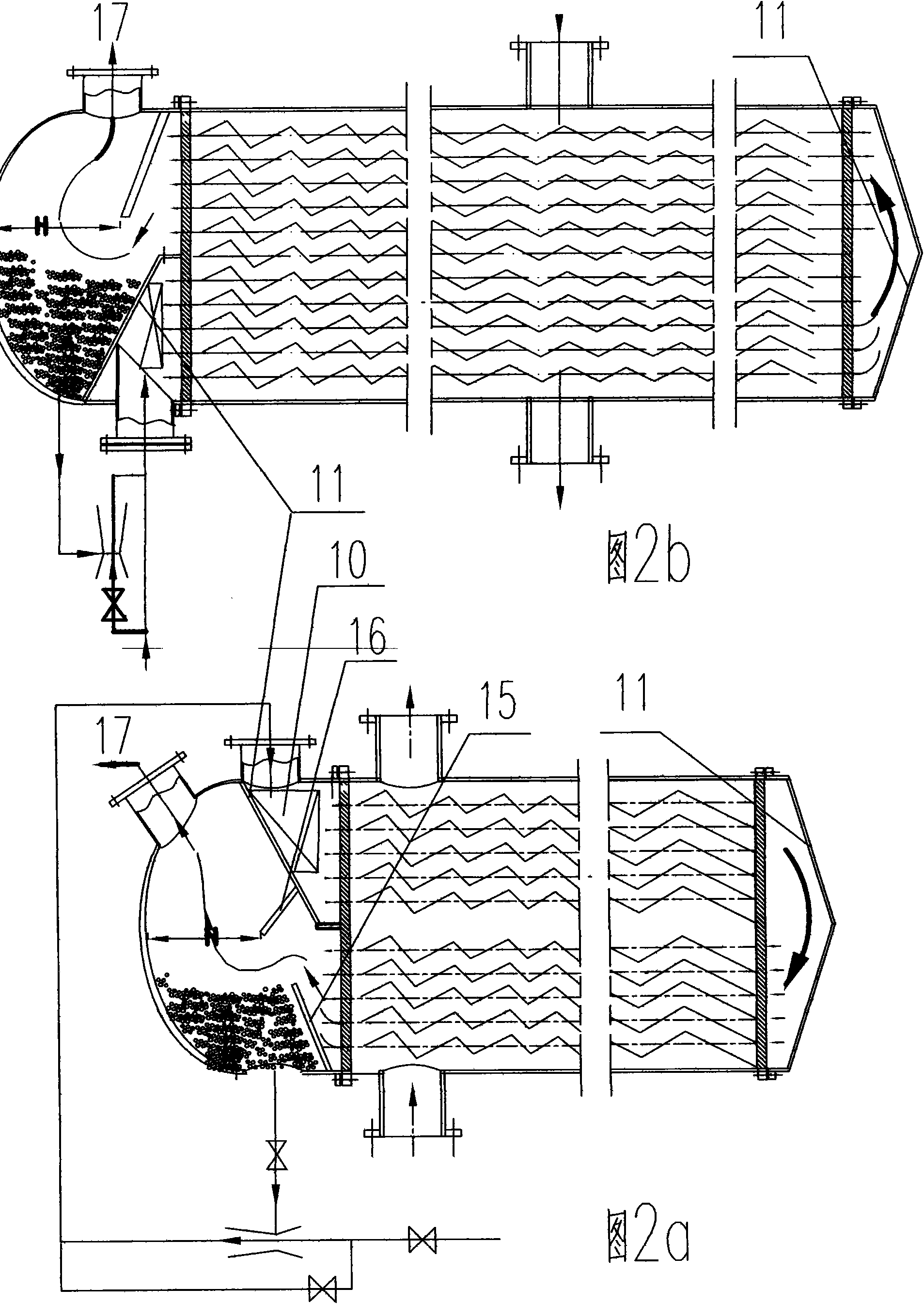

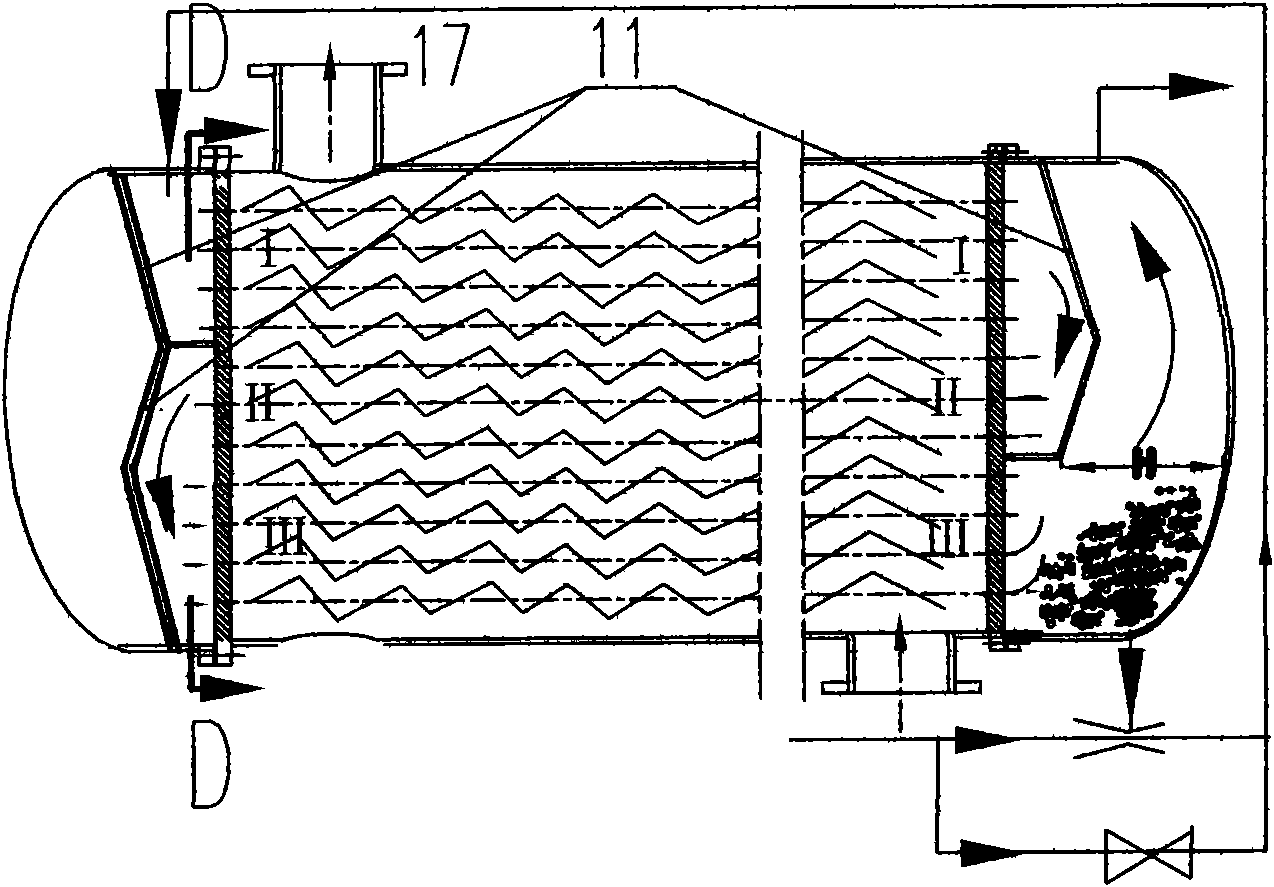

[0020] Attached below figure 1 , 1a , 1b, 1c, 2a, 2b, 3a, 3b, 4a, 4b, 4c, the present invention is described in further detail.

[0021] In the figure, 1 regulating valve 2 Venturi 3 fluidizing ball 4 accelerating elbow 5 heat exchange tube 6 steel wire helix 7 inlet pipeline 8 inlet pipe 9 partition uniform distribution plate 10 radial uniform distribution plate 11 uniform distribution cover 12 pressure bearing end Cover 13 Evenly distributed tube box 14 Tube plate 15 Circulation tank partition 16 Sand plate 17 Outlet tube 18 Outlet tube box 19 Maximum cross section 20 Fluidized ball circulation tank 21 Fixing frame

[0022] A vibrating spiral fluidized horizontal tube-and-tube heat exchanger, the main components of which are a uniformly distributed tube box 13, an outlet tube box 18, a heat exchange tube 5, a steel wire helix 6, a fluidizing ball 3, a Venturi 2, and a regulating valve 1. 7 inlet pipes and 8 outlet pipes. Each heat exchange tube 5 is provided with a steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com