Rotary flow aeration biological filter

A biological aerated filter and water flow technology are used in biological aerated filters, and lightweight materials are used as fillers. It can solve the problems of high pretreatment requirements, easy blockage of biological aerated filters, and large amount of backwashing water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

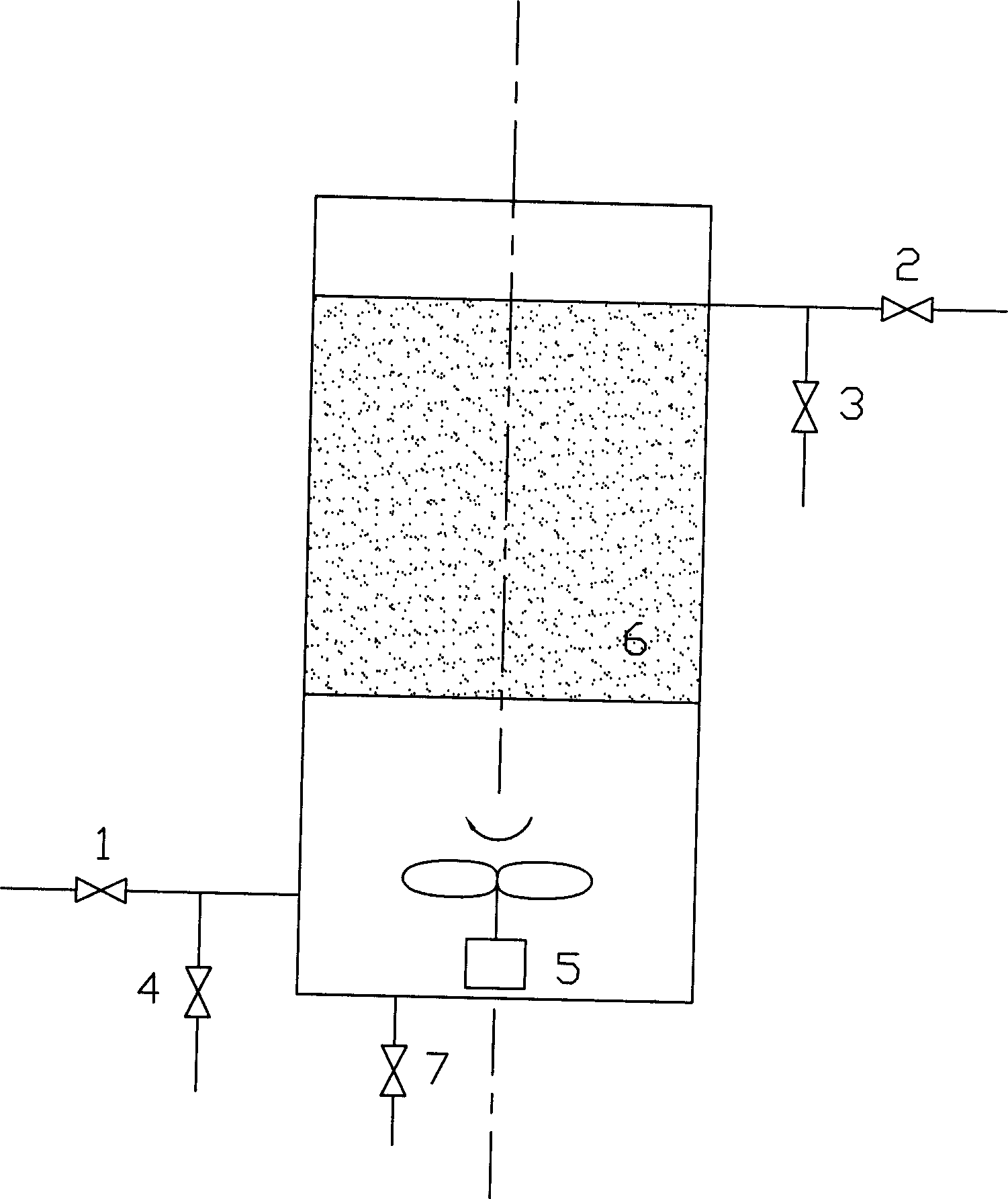

[0009] When the biological aerated filter normally treats sewage, open the valves 1 and 2, the sewage enters from the bottom valve 1, passes through the reaction and filtration of the filter material in the biological aerated filter, and the water is discharged from the upper valve 2. At this time, the valves 3 and 4 are closed. The air valve 7 opens the aeration. The submersible mixer 5 rotates at a slow speed to fully mix the incoming water with the sewage in the filter tank and distribute the water evenly.

[0010] When the filter water head increases and the water output decreases, the biological aerated filter stops the water intake and enters the flushing state. Close the valves 1, 2, 3, 4, 7; the submersible mixer 5 rotates rapidly, driving the water flow and the filter material to rotate, and the speed gradient G value generated by the stirring power in the water is 100-300s -1 In between, the stirring time is 10-20 minutes to make the biofilm on the filter material f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com